Gore (日本ゴア)

GORE High Temperature Capacitors for Oil And Gas Power Electronics

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: High Temperature Capacitors

Overview of High Temperature Capacitors

Power electronics in oil and gas downhole tools are subjected to some of the harshest operating conditions on the planet. Design teams have had to work around the challenges of legacy capacitor technologies: using multiple capacitors to meet power needs while overcoming de-rating, innovating specialty mounting techniques for shock & vibration, the use of dewar insulation systems, or even cooling systems to resist extreme temperatures.

But despite the number of incremental improvements, the critical weakness is hidden in the failure mode of traditional capacitor choices. For when they fail, they fail short leading to risk of downhole tool failure.

GORE High Temperature Capacitors reduce the risk of tool failure by delivering stable performance in harsh oil and gas downhole environments. Unlike traditional capacitors, Gore’s technology avoids sudden and complete failure for a more predictable mission completion.

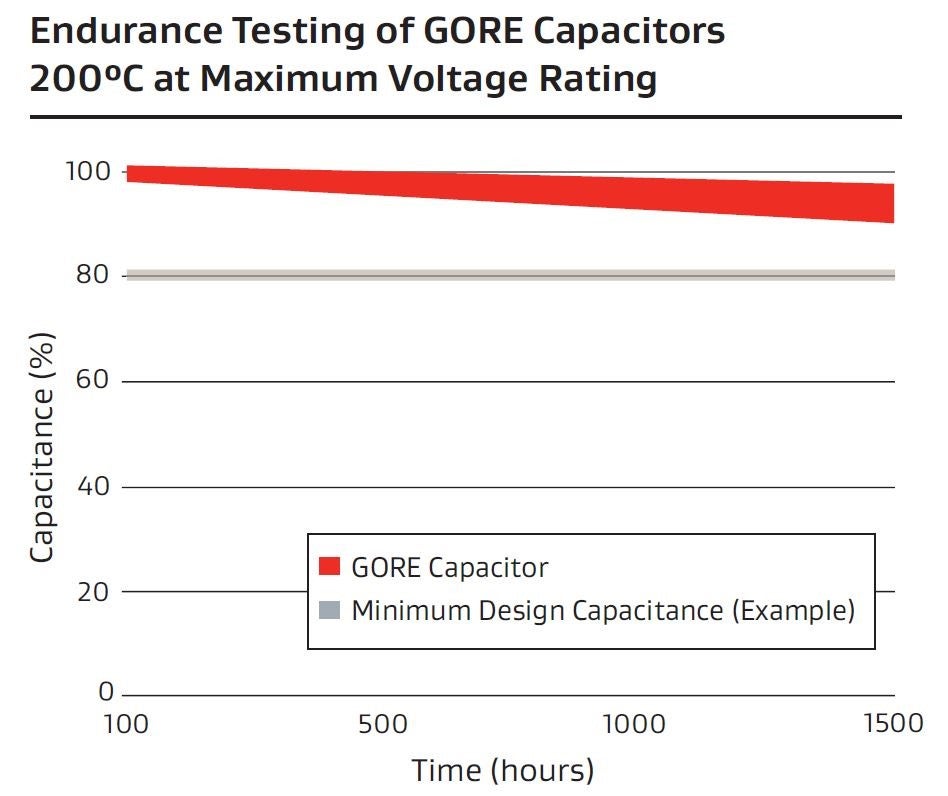

Endurance testing of 111 Gore capacitors at maximum operational ratings indicates 90% probability of capacitance performance. When considering an electronic system design that requires a minimum 80% starting capacitance to operate with stability, at least 95% of GORE™ capacitors will pass at 1000 hours and at least 91% at 1500 hours (95% confidence levels). For actual operating conditions below the maximum ratings, expectations of capacitor longevity can be substantially extended.

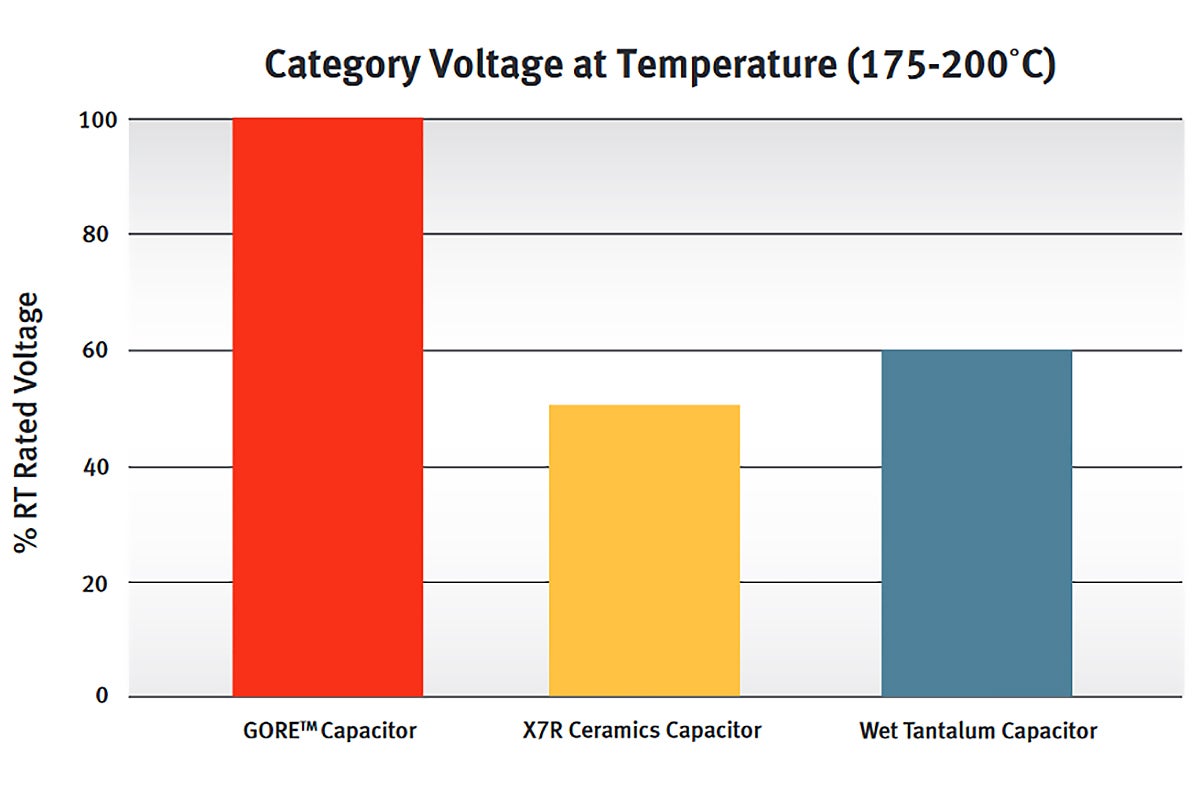

Simplified Design and Installation with Minimal De-rating

Traditional capacitors require substantial de-rating to meet the need for high capacitance and high voltage in high-temperature conditions. So, design engineers have to use large amounts of small capacitors, which can complicate system design, cause numerous potential failure points, and increase installation costs.

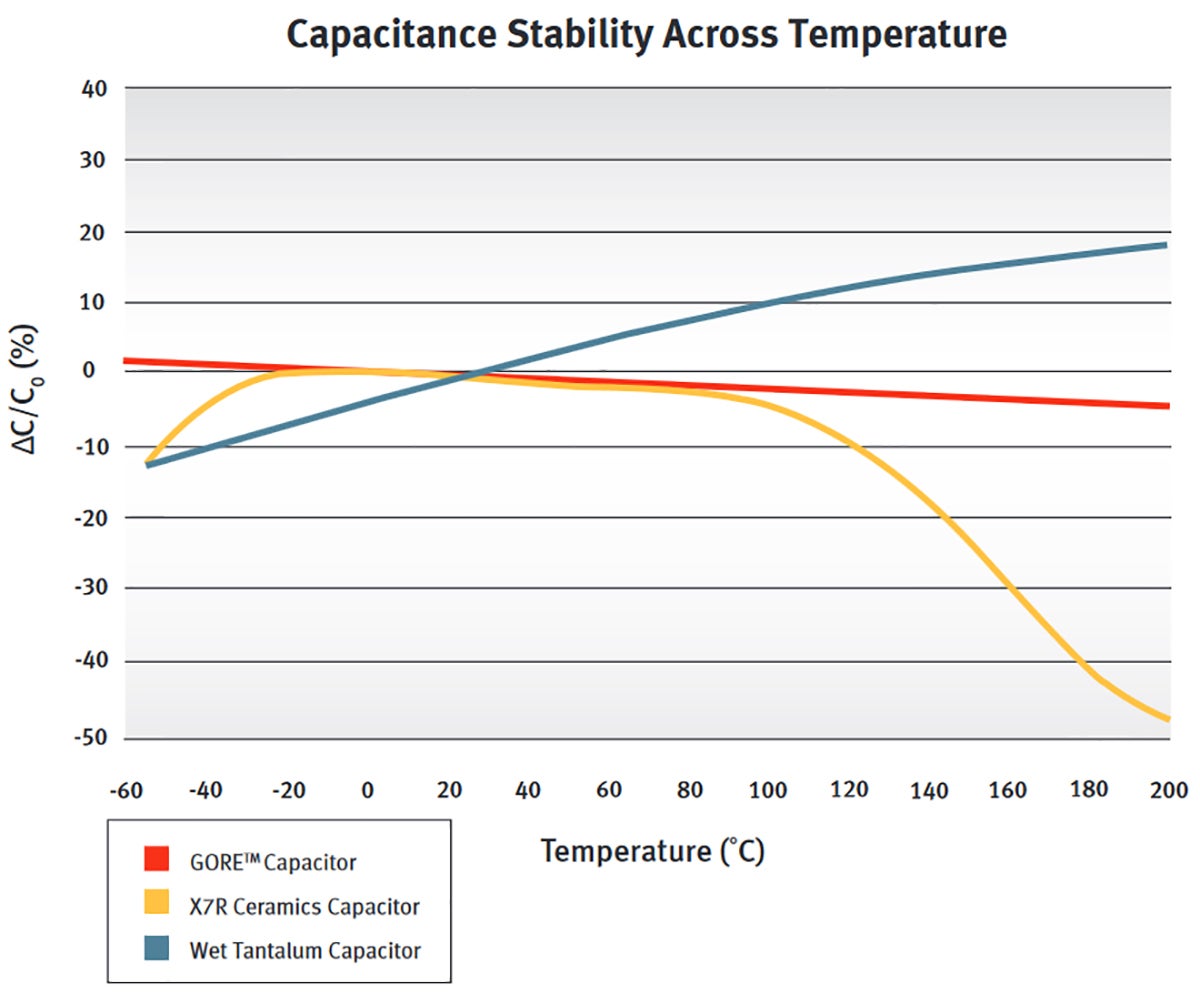

Alternatively, a single Gore capacitor offers a large amount of stable capacitance with minimal de-rating under high temperature and voltage conditions.

Benefits

- Increased tool reliability and reduced risk of unexpected failure

- Stable and predictable capacitance

- Withstand high temperatures and voltage spikes

- Withstand voltages up to 400 VDC and 200°C with minimal de-rating

- Withstand shock and vibration

- Reduce system design complexity and improve installation

Property Summary

| Property | Value |

|---|---|

| Capacitance Range | 1–100 µF (single element design) |

| Temperature Rating | -40–200°C (-67 – 392°F) |

| Voltage Rating | 400 VDC |

| Typical ESR | 20 –30 mΩ (50 µf @ 2 kHz) |

| Typical ESL | < 40 nH |

| Insulation Resistance (terminal-to-terminal) | > 100,000 MΩ x µF |

| Withstand Voltage (terminal-to-case) | 1500 VDC |

| Environmental Compliance | RoHS |