Gore (日本ゴア)

GORE High-Voltage Cables

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: High-Voltage Cables

Overview of High-Voltage Cables

Extend Product Life for High-Voltage Cables

Running cables in a spacecraft is time-consuming and difficult. GORE High-Voltage Cables reduce the frequency of this task by providing a minimum of 10,000 hours of reliable performance at maximum voltage ratings — ratings that are based on years of test data recorded under actual operating conditions.

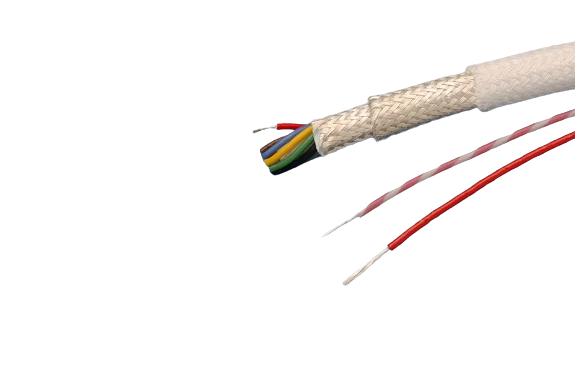

Available as hook-up wire, ribbon cable or round cable, GORE High-Voltage Cables are specifically designed for applications that require high reliability for long periods of time, such as power supplies and amplifiers, traveling wave tubes, and high-voltage routing.

The Science Behind the Cables

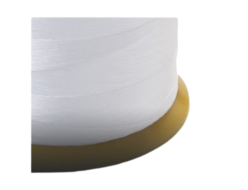

The key to the outstanding performance of GORE High-Voltage Cables is the proprietary material used in the cable insulation: expanded polytetrafluoroethylene (ePTFE). Using this proprietary technology, we have developed a specialized Corona-Resistant PTFE. Gas molecules trapped inside the insulation can ionize and cause corona discharge when high voltages are applied, ultimately causing damage to the insulation, which in turn causes more gas molecules to ionize.

GORE® CR-PTFE allows the gas molecules to escape through the membrane without damaging the insulation. Because PTFE fibers are chemically inert and thermally stable, GORE® High-Voltage Cables can be used even at cryogenic temperatures or as high as 300°C for short periods of time.

To protect against the excess gases that occur during ascent into orbit, an additional jacket made of microporous GORE-TEX® fibers can be added to the cables. This jacket allows gas molecules and air to flow completely out of the cable, thereby eliminating the possibility of damage to the cable.

Applications of High-Voltage Cables

GORE High-Voltage Cables deliver outstanding performance in critical applications, including:

- Traveling wave tubes (TWTs)

- Power supplies and routers

- High-voltage routing

The cables excel in demanding environments thanks to their Corona-Resistant (CR) PTFE insulation. These cables have supported critical space missions such as:

- European Communications Satellite (ECS)

- European Remote-Sensing Satellite (ERS)

- Hot Bird satellites

- Intelsat satellite communications

- RADARSAT satellites

For over 25 years, GORE has delivered highly reliable cable solutions to the space industry. Our cables boast a 100% success rate, reflecting our dedication to partnering with customers to create dependable and durable cables for high-stakes applications.

Features and Benefits of High-Voltage Cables

GORE High-Voltage Cables incorporate advanced Corona-Resistant (CR) PTFE insulation, offering these standout features:

- Chemical inertness and non-flammability

- High resistance to electromechanical stress cracking

- A wide range of AWG size options

These features translate into significant benefits for manufacturers and users:

- Exceptional reliability in extreme environments

- Long-lasting durability due to specialized insulation

- Consistent performance across a wide temperature range

- Trusted reliability from an ESA-qualified and ISO 9001:2000-certified manufacturing facility

Properties

All GORE High-Voltage Cables meet these technical specifications.

| Property | Value |

|---|---|

| Maximum Operating Voltage | 1.5 kV AC (3.0 kV DC) to 16 kV AC (36 kv DC) |

| Conductor | Silver-plated copper or copper alloy, true concentric |

| Insulation | Corona-resistant PTFE |

| Outer Jacket | Expanded PTFE and/or PTFE |

| Temperature Range | -200°C to +180°C |

Resources

Learn more about GORE High-Voltage Cables in a thorough data sheet and a white paper discussing the properties of cables that ensure peak electrical performance.