Gore (日本ゴア)

GORE Hybrid Round Cable For Harsh Environments

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Hybrid Round Cable

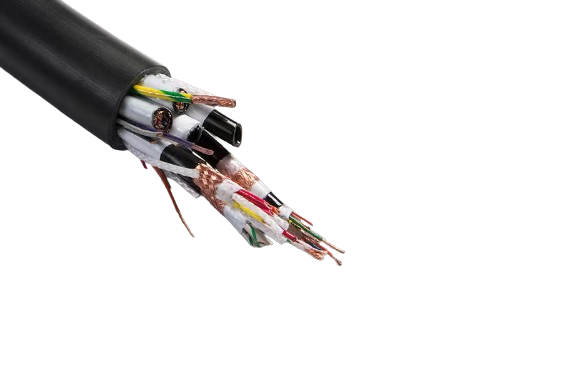

Overview of Hybrid Round Cable

Gore high-performance hybrid round cable is electrically and mechanically optimized for high performance in difficult applications. Rugged features, robust environmental protection, and high EMI/RFI shielding capabilities are available for computer, industrial, and military applications with stringent performance envelopes.

Unique configurations for optimal performance

Gore will help select materials and apply them to designs that deliver the required performance. Each component can be customized, from conductor to final jacket, to exact project specifications. Lines can be packaged individually or in groups to maximize function, fit, and long-term maintenance goals, for a cost-effective system that does not sacrifice electrical or mechanical performance.

Many packaging options

Single lines, twisted pairs, high-performance coax, fiber optic cable, power lines, and air and water lines can be combined in a single package.

Applications of Hybrid Round Cable

Computers

- Coaxial design

- Signal speed of 1.16 nsec/ft

- Controlled impedance

- High data rate

Telecommunications

- Twisted pair design

- Skew < 2.0 nsec/100 ft.

- Skew Optimized shielding

Test Equipment

- Hybrid design

- Low capacitance

- Controlled electricals

Military

- High shielding

- Ruggedized designs

- Reduced size and weight

Robotics

- Maximized flex life

- Suitable for harsh environments

- Electrical stability throughout flex

Benefits

- Precise electrical properties

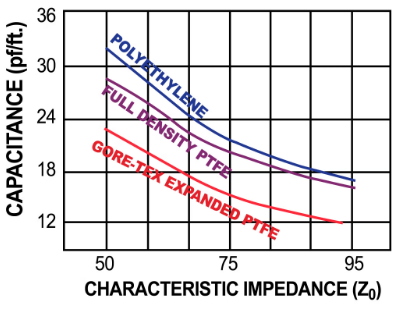

- Significantly lower capacitance

- Greater than 85 percent Vp

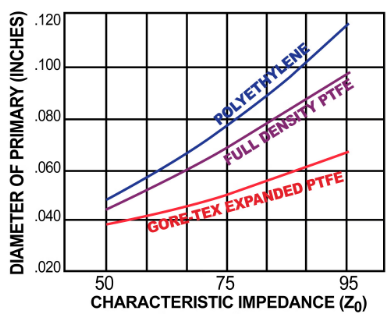

- Smaller size and weight for high-density applications

- High flex life in multiple axes

Properties of Hybrid Round Cable

1.3 Dielectric constant reduces capacitance

PTFE insulation’s dielectric constant is lower than any other flexible, homogeneous insulating material on the market, giving Gore round-cable assemblies significantly lower capacitance than cables insulated with conventional dielectrics. This reduces overall power consumption and keeps systems efficient.

85 percent Vp reduces system delay

ePTFE dielectric material allows exceptionally fast signal speeds. Signals exceeding 85 percent of the speed of light allow computers and telecom systems to perform at peak capacity, with no signal-delay bottlenecks. W. L. Gore & Associates offers a variety of control mechanisms that allow determination of the exact electrical and timing characteristics of the round-cable assembly.

| Insulation | Dielectric Constant | Velocity of Propagation (%) | Temperature Limits (C) | Flammability (L01) |

|---|---|---|---|---|

| Gore ePTFE | 1.3 | >85 | -70 to +260 | >95 |

| PTFE | 2.1 | 70 | -70 to +200 | >95 |

| FEP | 2.1 | 70 | -70 to +260 | >95 |

| Irradiated polyolefin | 2.5 | 65 | -50 to +125 | 29 |

| Polyethylene | 2.5 | 65 | -60 to +80 |

Reduced Size and Weight Increases System Density

Because Gore ePTFE insulation has a low dielectric constant, less of it is used in Gore cables, reducing the overall size and weight of the interconnect. With possible weight savings as high as 70 percent, Gore round-cable assemblies are ideal for space and airborne applications and computer systems that require high-density interconnects.

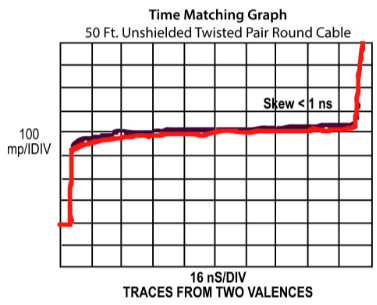

Precise process and material control minimizes signal skew

Gore high-performance round cables and assemblies allow better control of problems associated with impedance mismatch, rise-time degradation, EMI, and crosstalk. Gore has developed manufacturing processes that control signal skew to 25 picoseconds in a 10 ft. length. This makes Gore assemblies ideal for clock line and other critical time-matching situations.

Gore cable and assemblies can be electrically tuned to compensate for lack of fine tuning capability in other system components. Electrical tuning also reduces edge distortion.

Years of experience in tape wrapping and other construction methods has taught us how to consistently maintain cable concentricity, allowing reliable time-matching. Gore delivers tight time-matching at very high velocities without compromising fidelity.

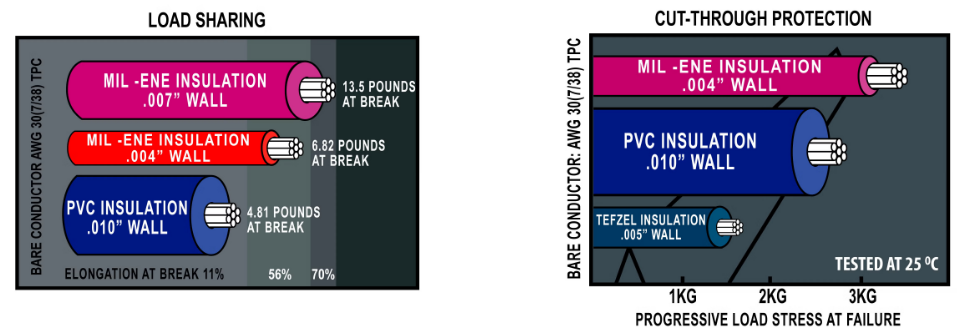

MIL-ENE insulation increases conductor strength and reduces cut-through

MIL-ENE insulation is an extremely tough, thin polyester laminate. This high-modulus insulation has a unique load-sharing ability that actually increases the strength of the conductor.

It also protects the conductors from cut-through better than any other flexible insulation. This increase in strength allows use of smaller gauge conductors in many applications where larger conductors have been specified for mechanical strength only.

Thin MIL-ENE insulation reduces weight and space requirements

The extreme thinness of MIL-ENE insulation allows reduction in size of component wires. A 0.004 in. wall of MIL-ENE dielectric can replace 0.010 to 0.020 in. of common insulations and still maintain the same voltage rating.

Thinner primary insulation provides high flexibility and denser cables standard or coiled

A tough, thin primary insulation means a smaller cable, and a smaller cable means significantly more flexibility (because the bending ease of a bundle of wires is inversely proportional to the fourth power of the radius of the cable). For example, a 50 percent smaller cable is 94 percent more flexible.

The best performing coil cords are made of smaller cables. Gore coil cords have excellent retentive memory, long flex life, and long-term reliability. They perform longer and better in the most demanding applications.