Gore (日本ゴア)

GORE LYOGUARD Freeze-Drying Trays

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Freeze-Drying Trays

Overview of Freeze-Drying Trays

PROTECT YOUR OPERATORS AND ELIMINATE TRAY CLEANING

Keeping liquid or lyophilized API in stainless steel trays is a challenging and time-consuming problem during processing. GORE LYOGUARD Freeze-Drying Trays were designed in consultation with industry experts to contain product during the freeze-drying process. For nearly 20 years, manufacturers have trusted GORE LYOGUARD Trays to help minimize the risk of exposure to APIs and Highly-Potent APIs, and to enable operators to spend less time worrying about product ejection and cleaning.

These disposable trays are ideal bulk lyophilization containers, because the GORE Membrane — an integrated 100% ePTFE tray cover — can enable improved process efficiencies and yields, and reduced risk of operator exposure.

ADDRESSING UNMET NEEDS IN BULK TRAY LYOPHILIZATION

Understand the benefits of single-use disposable LYOGUARD Freeze-drying trays compared to stainless steel trays for lyophilization

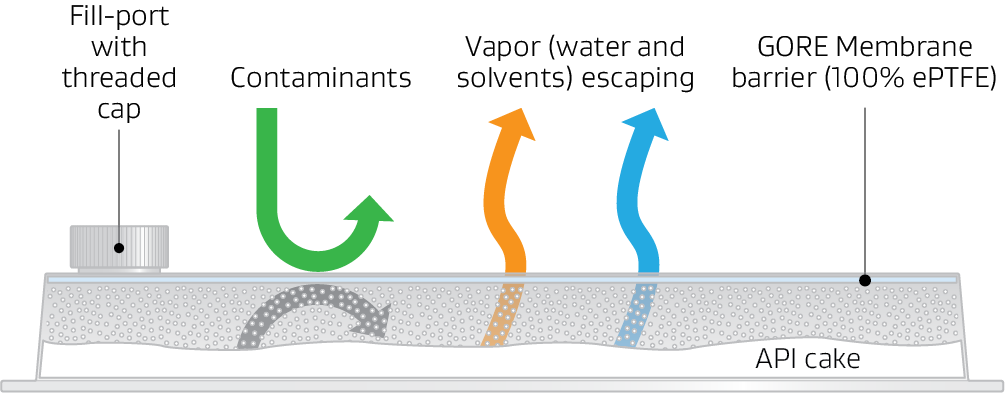

Unique to this lyophilization tray is its GORE Membrane — an integrated 100% ePTFE tray cover that provides:

- a built-in protective barrier that keeps contaminants out

- a permanently-attached cover to safely contain product, unlike steel trays

- a high vapor transmission rate, so water and solvent vapors are readily released

Gore’s unique microporous ePTFE membrane enables high-efficiency lyophilization yet provides a barrier to keep product in the tray.

LYOPHILIZATION TRAY APPLICATIONS

GORE LYOGUARD Freeze-Drying Trays can simplify processing by eliminating many cleaning operations, and can enable greater safety in handling a wide variety of fluid and lyophilized drug products, including:

- polypeptides

- oligonucleotides

- vaccine adjuvants including lipid nanoparticles

- microbiome therapeutics

The integrated GORE Membrane enables exceptional mass transfer while the thin, conforming tray bottom facilitates efficient thermal transfer

Filling and freeze-drying within GORE LYOGUARD Trays is easy and efficient, as the tray design can reduce the chance of contamination and the risk of operator exposure — or loss of valuable product — due to fly-out or ejection.

For virtually any lyophilized drug formulation or lyophilized drug development process, GORE LYOGUARD Freeze-Drying Trays totally eliminate tray cleaning, and can reduce the chance of accidental spills and related cleanings of the lyophilization chamber.

Lyophilization tray for bacterial applications

An area of intense clinical focus is preservation of bacteria by lyophilization, whether for traditional therapeutics or emerging microbiome applications relating to gut microbiota, gut flora or live biotherapeutic product. GORE LYOGUARD Freeze-Drying Trays are designed to support a wide range of formulations for freeze-drying of bacteria and lyophilization of nanoparticles because they can enable greater operator safety and process efficiency, and reduce risk of product contamination — all of which are essential in lyophilization of bacterial culture.

GORE LYOGUARD Freeze-Drying Trays benefits:

| CONTAINMENT | |

|---|---|

| Integrated membrane top allows for high vapor transmission while also providing containment |

|

| THROUGHPUT | |

| Single-use, disposable (SUD) trays save time |

|

| COMPATIBILITY | |

| Easily integrated with your processes |

|

| CONFIDENCE | |

| Gore quality is assured |

|

Related Products

-

GORE Insulated Wires For Oil And Gas Downhole Equipment

-

GORE Microfiltration Media For Medical Devices

-

GORE High Speed Data Cables for Semiconductor Production Equipment

-

GORE STA-PURE PCS Series Pump Tubing

-

GORE Acoustic Vents for Industrial Applications

-

GORE DVI Cables (Digital Only) for Defense Aircraft