Gore (日本ゴア)

GORE NOx and NH3 Catalytic Filter Bags

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Catalytic Filter Bags

Overview of Catalytic Filter Bags

NOx and NH3 Catalytic Filter Bags

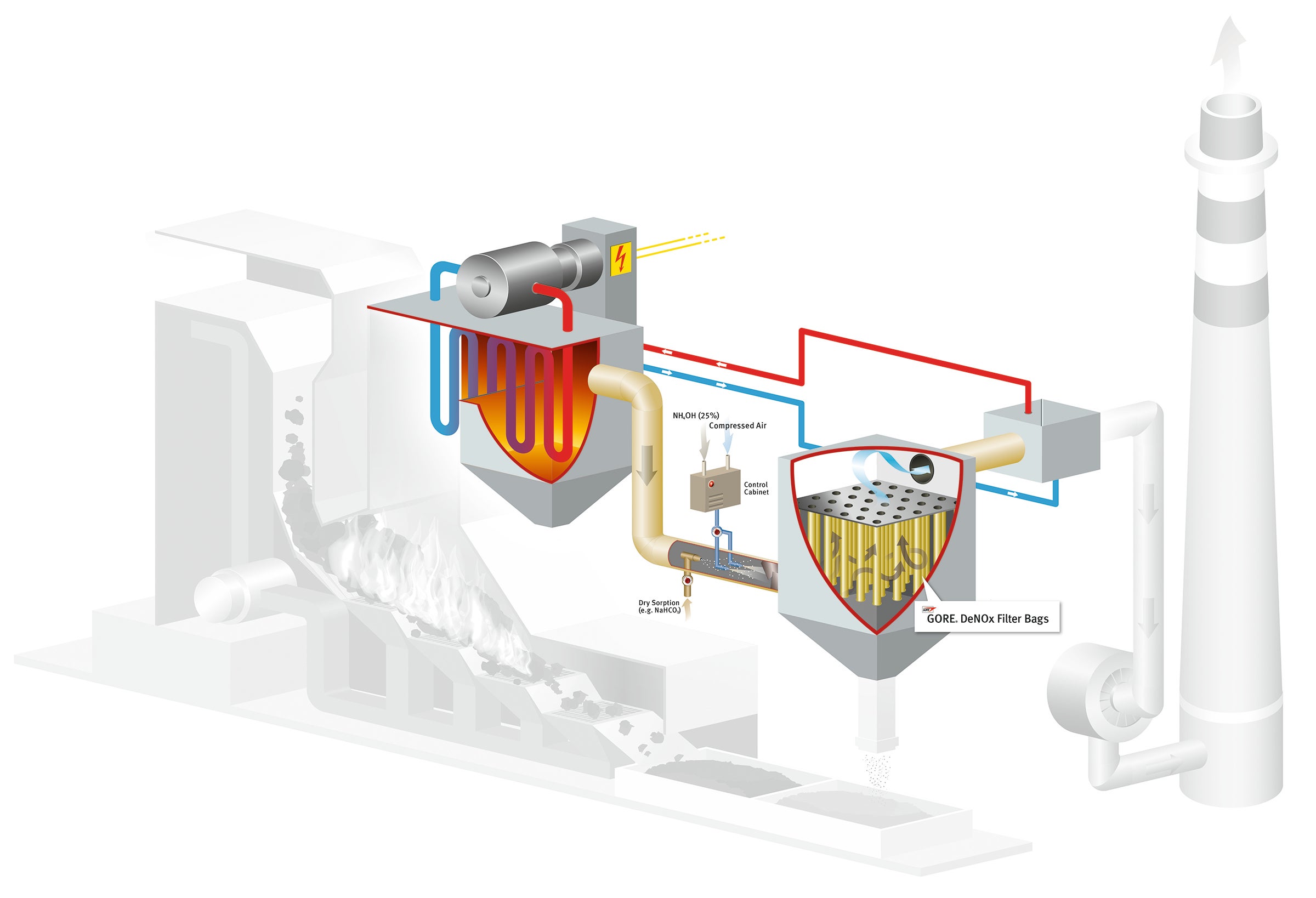

Meeting ammonia and NOx reduction targets is a significant challenge for industrial processes dealing with increasingly stringent emissions regulations. Though SCR towers will help you deal with NOx, the investment costs are high and there remains the risk of ammonia slip. Why not choose a more cost-effective and more reliable alternative? Our catalytic filter bags achieve both NOx reduction and ammonia filtration within your existing baghouse, with no need to do anything more than change your filter bags.

Upgrade your baghouse to an SCR

With more than 15 years of experience in catalytic NOx reduction, Gore has developed a completely new approach to NOx control using a NOx removal catalyst within our filter bags. Acting as an SCR without the cost of installing an SCR tower, our specially developed DeNOx process enables you to cut NOx and ammonia emissions, effectively and efficiently.

By using your existing filter bags, with no other equipment changes required, you benefit from:

- Low capital investment for new equipment

- Minor changes to process and operation

- No additional footprint

- No differential pressure increase

- Easy to install. Easy to maintain.

GORE DeNOx Filter Bags are also a perfect choice for new plants.

- Simplify flue gas treatment line

- Save energy costs

- Reduce capital investment cost

The Challenge of NOx and NH3 Compliance

Meeting the latest NOx and NH3 compliance requirements can be difficult and costly.

- SNCR systems often struggle to achieve low enough levels of NOx and NH3 at the same time, leaving you in danger of non-compliance.

- SCR towers come with significant investment cost, especially for existing facilities. There are also limitations in terms of floorspace, overhead clearance, ID fan capacity and other unexpected impacts. Retrofitting an SCR to an existing facility typically requires 30-50 % higher investment than an SCR purchased with the initial plant construction.

Our specially designed ammonia filter bags filter NOx and NH3 to deliver the compliance you need at a price you can afford.

Full compliance. Less costs.

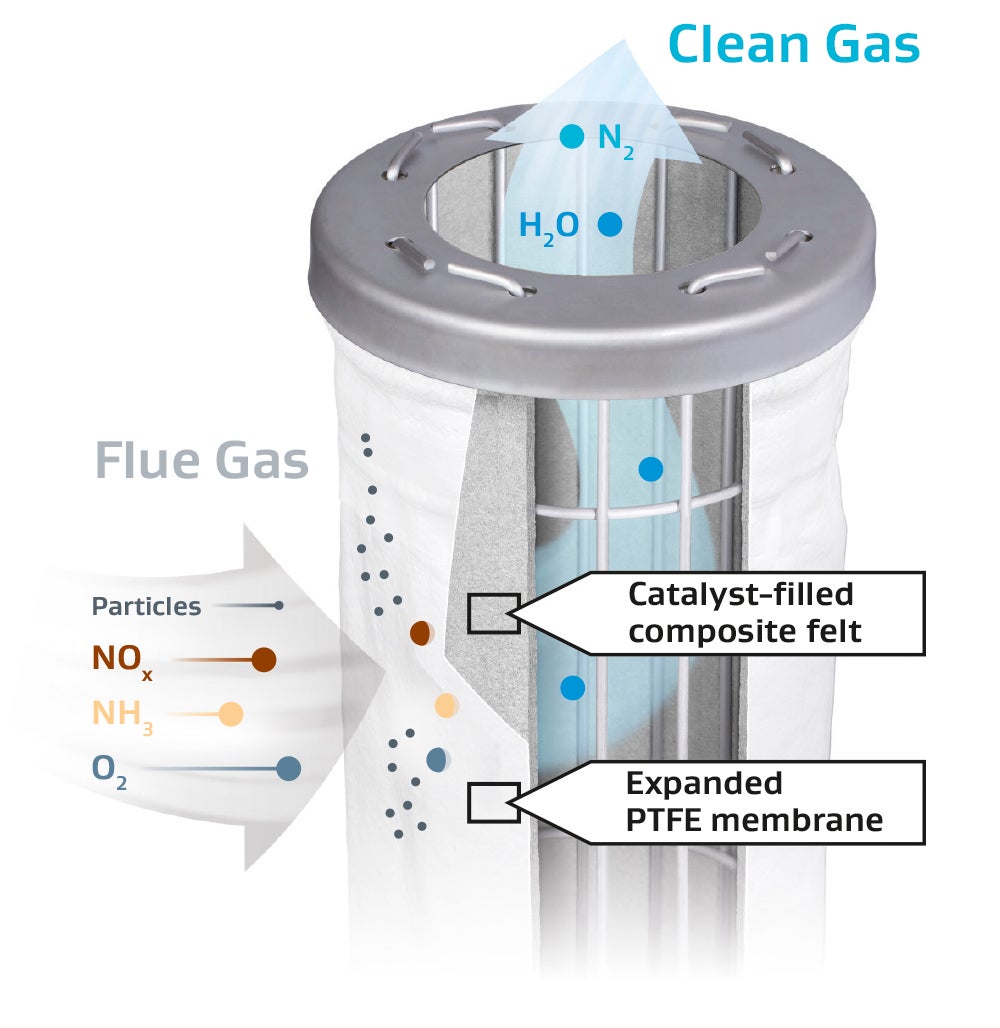

Gore has developed a dual-function filter bag that simultaneously provides best-in-class particulate filtration and high-efficiency NOx reduction. The Gore technology combines an ePTFE membrane for particulate removal with a PTFE-based catalytic felt for simultaneous reduction of NOx and NH3. Because the GORE Membrane effectively traps dirt and dust, it also protects the catalyst and extends its performance-life, reducing your total cost of ownership.

Proven ammonia filter bag technology with NOx removal catalyst

Our GORE DeNOx Catalytic Filter Bags have been proven in full scale references around the world. The conversion is simple, since no new equipment is required – it’s just a straightforward filter bag change. Some minor operating procedure changes are needed to maximise NOx and NH3 reduction. But we are here at every stage to help you with the modification, installation and start-up of the process.