Gore (日本ゴア)

GORE Packaging Vents for Biostimulants

Manufacturer: Gore (日本ゴア)

Made in Japan

Product type: Packaging Vents

Overview of Packaging Vents

Biostimulants: A Special Product with Special Packaging Needs

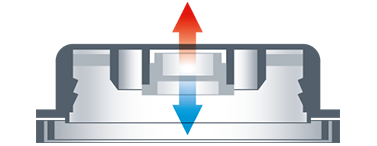

GORE® Packaging Vents allow for constant pressure equalization – making them a perfect choice for biostimulants product packaging.

Liquid biostimulants are an innovative and valuable solution that can help farmers meet increasingly challenging sustainability targets without compromising on yield. What makes biostimulants so great, also makes them particularly challenging for packaging, transportation, and storage: Their organic formulation components contain active ingredients that will ferment and release gases.

When failing to manage the off-gassing process, containers may bloat and ultimately leak or even burst. Wasting precious product this way does not look pretty, nor is it sustainable and it will most likely leave customers dissatisfied.

Transportation adds another layer of complexity beyond the manufacturers control. Bloating or collapsing containers due to rapid changes in temperature or altitude, are not a rare occurrence.

But there is an easy fix.

With GORE® Packaging Vents, you can simply adjust your packaging to minimize all these risks. Our vents reliably and continuously equalize pressure to minimize the potential for leaks and maintain the integrity of containers and their contents.

AVOID LEAKAGE

KEEP YOUR PACKAGING SAFE AND CLEAN

PROTECT YOUR BRAND IMAGE

ENHANCE PRODUCT VALUE

Packaging Expertise for More Sustainability & Design Flexibility

Did you know: Managing off-gassing safely enables thinner container walls, which can allow for reduction in packaging weight. This way, using GORE® Packaging Vents can add an additional layer of sustainability to your product and your brand – a big plus in times of increasing interest in solutions that are easier on the environment.

GORE® Packaging Vents: Higher Airflow, Excellent Repellency, No Spills

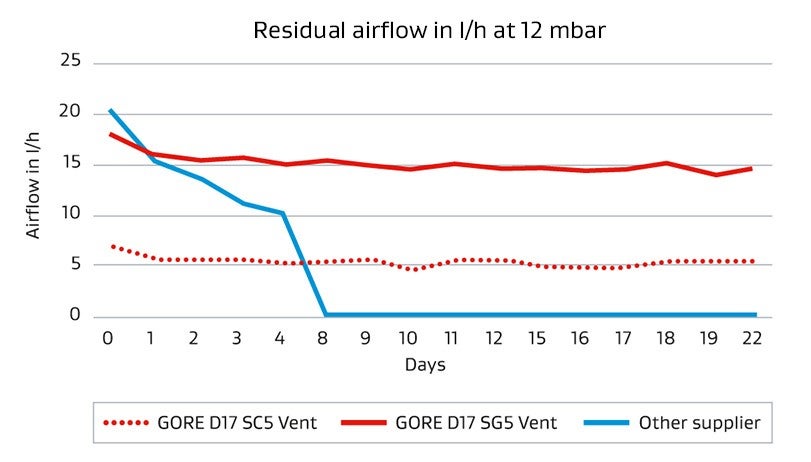

At Gore, we conduct numerous lab test to make sure our products meet the highest industry standards and satisfy our customers. For example, we test our GORE® Packaging Vents for residual airflow as well as repellency properties with real biostimulants on the market.

A comparison between GORE® Packaging Vents (red) and a standard product (blue): the vent of another supplier leaked just eight days after contact with an amino acid-based biostimulant due to pressure buildup, caused by poor repellency. The GORE D17 SG5 vent’s airflow remained higher – even after liquid contact.

GORE® Packaging Vents: Our membrane has excellent roll-off properties, so it easily sheds liquids and airflow remains unimpeded.

Competitors: Other membranes have poor roll-off properties, so liquids cling and clog the membrane reducing airflow.

Want to experience first-hand the benefits of GORE® Packaging Vents and the superior ePTFE membrane used, which have been proven in independent lab tests? Request free samples of our innovative venting solution for biostimulants packaging and see for yourself!

Application & Offering

Don’t Adjust Your Formulation, Adjust Your Packaging – With Gore, It’s That Easy!

GORE® Packaging Vents can be easily implemented into your biostimulants packaging. Our Plug-In Vents for example can be installed via press-fit or snap-fit. Available for containers sizes from 0.2 to 1,500 liters, they can be integrated into the closures of industrial drums, bottles, jerry cans and IBCs – one venting solution across all containers.

GORE ALWAYS HAS THE RIGHT VENT FOR YOUR BIOSTIMULANTS PACKAGING

The new Plug-In Vent D17 SG5 and the Vented Pulp Induction Liner complement our existing offering – the 363 Foam Liner. This puts three packaging solutions at your disposal that optimally address the most common and troublesome challenges biostimulants packaging comes with.

NEW Plug-In Vent D17 SG5:

One venting solution across bottles and jerry cans: Plug-In Vents can easily be installed via press-fit or snap-fit. Available for containers sizes from 1 to 60 liters. Plug-In Vents D38 SG5 are available for container sizes from 60 to 1,500 liters.

NEW Pulp Induction Liners:

Suitable for biostimulant bottles up to 20 liters. The weldable installation ensures tamper-evidence, and the special membrane construction provides breathability for off-gassing liquids.

Foam Liners:

Two Series, with full-surface membranes, for all flat-cap designs featuring easy drop-in replacements for all single-point or unvented liners. Available for containers up to 30 liters.