Gore (日本ゴア)

GORE Pair Thermal Insulation With Graphite for Better Heat Spreading

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Pair Thermal Insulation

Overview of Pair Thermal Insulation

Thermal engineers use graphite, heat pipes and vapor chambers to spread and dissipate heat across a larger area to improve device performance. As thermal spreading requirements increase, these thermal solutions can still fail to reduce hot spots due to insufficient thermal resistance in the z-direction, which allows heat to reach device surfaces and form hot spots.

With GORE Thermal Insulation, you can now improve the effectiveness of your thermal spreading solutions. With a through-plane thermal conductivity (kz) significantly lower than air, enabled by premium aerogel technology, GORE Thermal Insulation will enhance the heat-spreading ratio and outperform system-level air gaps. Used in conjunction with heat spreaders, it can create a higher-performing thermal design.

Graphite Heat Spreaders

The thermal conductivity of graphite varies, depending on whether it is natural or synthetic graphite, the manufacturer, and the thickness. Graphite is also highly anisotropic, meaning its conductivity in-plane is different than its conductivity through-plane. Graphite sheet thermal conductivity is higher In-plane than it is through-plane.

GRAPHITE SHEET THERMAL PROPERTIES

Graphite-Only Solutions

High thermal-conductivity graphite sheets offer a desirable combination of low graphite heat resistance in-plane, and moderately low graphite heat resistance through-plane. This combination can offer ideal thermal conductivity properties:

- In-plane conductivity in the range of 600–1900 W/m·K, along with

- Through-plane conductivity in the range of 3–20 W/m·K.*

These properties combine to give high thermal-conductivity graphite sheets an anisotropic ratio of ~500:1.

Graphite Combined with GORE Thermal Insulation

However, when graphite is combined with GORE Thermal Insulation, which has an even lower through-plane conductivity of 0.020 W/m·K, the anisotropic ratio can be increased by 100–1000x, leading to enhanced thermal spreading.

Using Graphite and Insulation Together

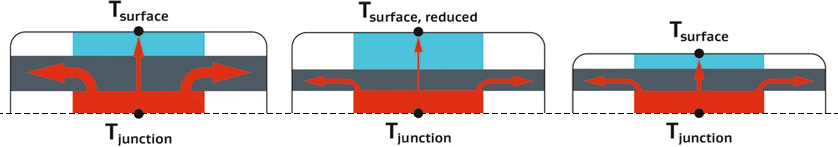

Materials with a high thermal conductivity like graphite sheets have been widely adopted to spread heat within a mobile device. Graphite sheets in phones are the go-to thermal management technique. The issue that thermal designers run into is while graphite manufacturers have made large strides in lowering the through-plane conductivity, it is still high enough to transmit heat to the surface. To account for this, designers incorporate a large air gap between graphite and the phone surface to prevent heat transfer. This air gap takes up space which designers would prefer to use for more graphite, in order to better spread heat away from the processor, and ultimately improve processor performance.

Combining thermal insulation with high-conductivity graphite sheet materials lets designers replace the large air gap with a thinner piece of insulation that leaves space to add more graphite. This combined solution will have greater capacity to spread more heat away from the processor, and run the processor at higher powers — delivering more performance to end-users.

| Increase Performance with GORE Thermal Insulation | Reduce Hotspot Temperature with GORE Thermal Insulation | Thinner Product Design with GORE Thermal Insulation |

|---|---|---|

|

|

|

| ||

| ||

Flexible Graphite

In many mobile devices, there is a desire for a flexible graphite sheet for thermal management. This could be due to new form factors like foldable phones, curved devices like AR/VR glasses, or due to internal component configurations that require non-flat graphite.

However, concerns about the flexible graphite sheet thermal conductivity can arise — either because the flexing causes structural changes in the graphite, or because there will be an uneven air gap above the graphite, increasing the likelihood of surface hot spots above regions with the thinnest air gaps. In the case of surface hot spots, insulation can help improve the performance of flexible graphite by providing a solid material that is consistent in both thickness and thermal resistance, ensuring a thermal barrier between the graphite and device surface. The compressibility of the insulation can also help to hold flexible graphite in place.

Graphite vs. Thermal Paste and TIMs

Graphite is advantageous in mobile devices when heat needs to be moved in-plane, along the length and width of the device. Thermal pastes and thermal interface materials (TIMs) are used to move heat in the through-plane direction, or up and down in the device. Thermal pastes and TIMs are often placed between the processor and the graphite to help move the heat as quickly as possible into the graphite, which helps to remove heat and keep the device running at top performance.

Combining a graphite sheet with a thermal interface material is often the preferred method as this uses solid-state materials, rather than a paste that can move over time. GORE® Thermal Insulation should be used on the other side of the graphite to prevent the heat from being transmitted through-plane to the surface and causing a hot spot.

Related Products

-

GORE 1000 Series Gasket Tape

-

GORE Ozonation Modules for Semiconductor & Microelectronics Processing

-

GORE ASW Type Space Cables (Anti-Static Wire)

-

GORE Hook-up Wire for Defense Aircraft

-

GORE Screw In Series Protective Vents for Solar Energy Systems

-

GORE High Temperature Capacitors for Oil And Gas Power Electronics