Gore (日本ゴア)

GORE PEM for Water Electrolysis

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: PEM

Overview of PEM

Green hydrogen production must scale up significantly to achieve our net-zero ambitions. However, the water electrolysis (WE) market is a challenging operational landscape.

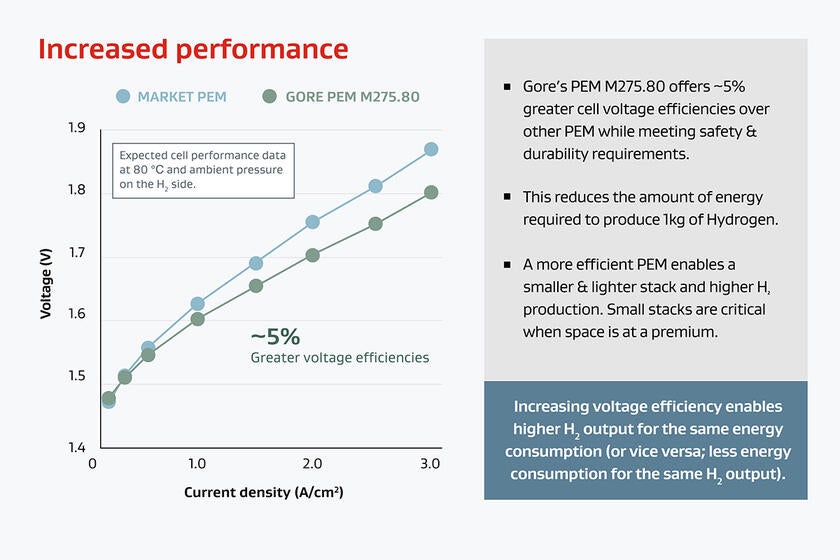

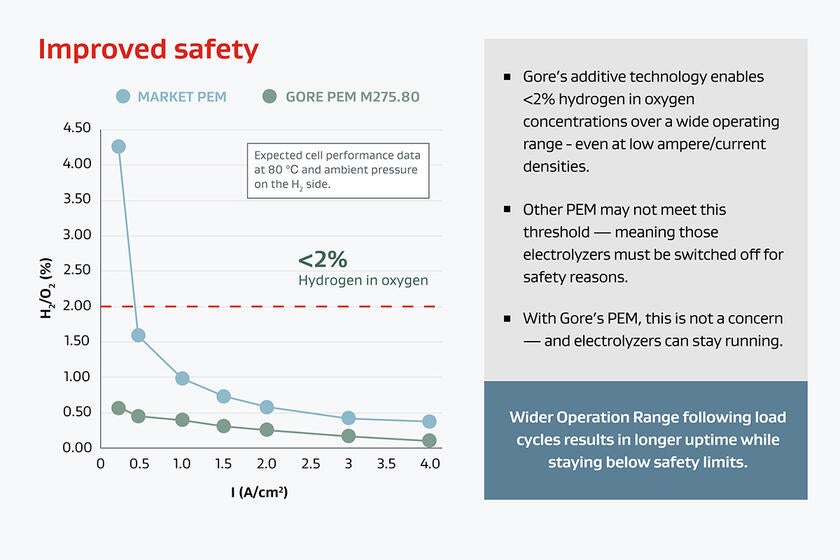

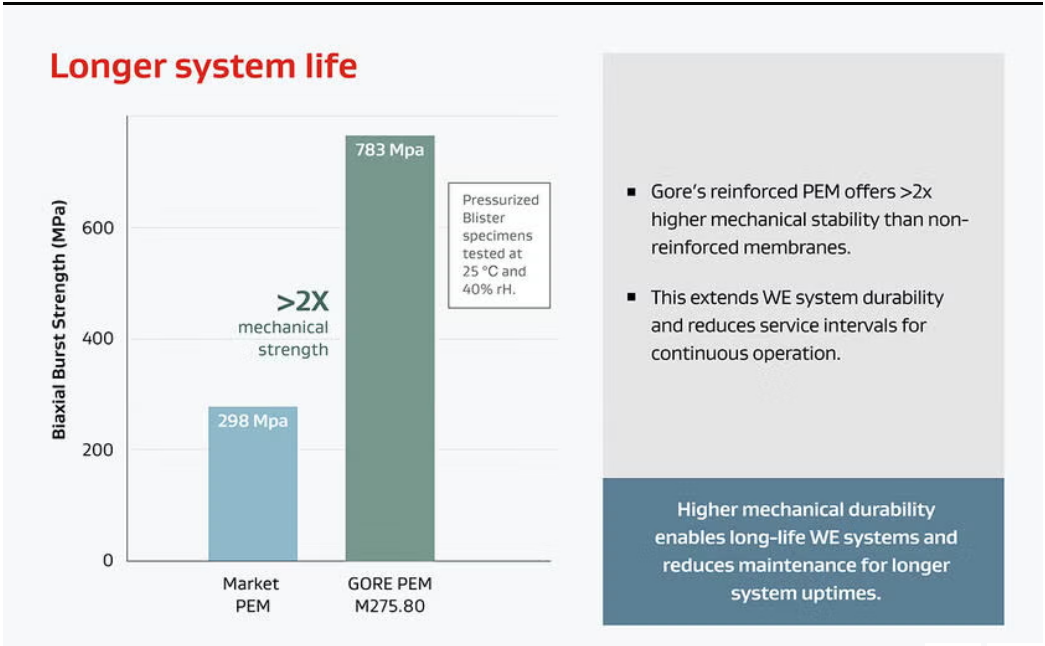

Engineers must solve the “system dilemma” of optimizing performance, safety and durability — where strengthening one vector means compromising on the others.

GORE® PEM for Water Electrolysis M275.80 breaks through performance barriers by optimizing all three vectors at the same time.

Our advanced membrane achieves new levels of hydrogen electrolysis efficiency and scalability, lowering the levelized cost of hydrogen (LCOH).

For almost three decades, we’ve led the market in producing proton exchange membranes (PEM) for fuel cells.

Product Benefits

Advantages of GORE PEM for Water Electrolysis

Water electrolysis OPEX must be reduced to achieve the LCOH necessary for large-scale WE commercialisation.

Our advanced material attributes tackle technology trade-offs, improving stack efficiency, reducing hydrogen plant operating expenses and mitigating risks in hydrogen production.

Gore: a materials science company

Our technical expertise allows us to engineer PEM to meet the individual requirements of the most demanding applications.

For PEM water electrolysis systems, we designed and developed a membrane that is both very thin and very stable — enabling effective, durable and safe hydrogen production.

| Gore’s proprietary ePTFE-reinforced layer | Unique perfluorinated ionomer | Advanced additive technology |

|---|---|---|

|  |  |

| Improving durability and performance with thin, highly conductive, mechanically durable membranes. | Enabling increased performance with high proton conductance + high voltage efficiency | Providing better durability and safety with enhanced chemical durability + reduced H2 crossover |

Gore has been at the forefront of PEM technology for nearly three decades, championing every aspect of PEM production from design to development to delivery.

Our engineering expertise and global supply chain capabilities are ready to support multi-Gigawatt water electrolysis installations — immediately.

| Industry & Application Expertise

|

| Quality Assurance

|

| Production Excellence

|

| Vertical Integration

|

| Non-profit CollaborationEngaging and collaborating with key:

|

Technical Specifications

GORE PEM M275.80 Technical Data

| Physical Characteristics | |

|---|---|

| Thickness1 [µm] | 80 |

| Tensile strength1 in Machine Direction [MPa] | 55 |

| Tensile strength1 in Transverse Direction [MPa] | 55 |

| Proton resistance2 [mOhcm²] | 57 |

| H2 permeance3 [mA/cm²/MPa] | 7 |

| Roll Properties | |

|---|---|

| Standard roll widths [mm] | 320, 400, 580 |

| Length [m] | 100 |

| Orientation | Product in roll form is shipped with the membrane anode side facing outwards |

| Quality Assurance | |

|---|---|

| Product visual inspection for defects | 100% automated |

| Clean room standard ISO 14644-1 | Class 7 (Class 10,000) |

1 Measurements taken with membrane conditioned to 23 °C, 50% relative humidity (RH).

2 Proton resistance measurements taken by high frequency resistance method. Membrane impedance taken at zero imaginary impedance.

3 Hydrogen permeance measurements taken by cyclic voltammetry (CV).

Related Products

-

GORE Type SPM Space Cables For LEO Applications

-

GORE Molded Assemblies

-

GORE PHASEFLEX Microwave/RF Test Assemblies 110 GHz

-

GORE DVI Cables (Digital Only) for Defense Land Systems

-

GORE Acoustic Vents for Industrial Applications

-

GORE Type SPLD Space Cables For Geostationary Earth Orbit (GEO) Applications