Gore (日本ゴア)

GORE PHASEFLEX Microwave/RF Test Assemblies 110 GHz

anufacturer: Gore (日本ゴア)

Made in Japan

Model: Microwave/RF Test Assemblies

Overview of Microwave/RF Test Assemblies

A recent study showed that globally more than 75% of microwave/RF cable assemblies are replaced frequently due to damage during installation or operation. So, cable assemblies must be durable enough to withstand continuous movement, flexing, and exposure to environmental conditions while maintaining reliable electrical performance over time.

Rugged Construction Delivers Longer Service Life

Our portfolio of GORE PHASEFLEX Microwave/RF Test Assemblies includes an 110 GHz version that can be flexed, formed, or repositioned without damage while providing excellent stability with flexure and temperature. These rugged, lightweight assemblies provide reliable electrical and mechanical performance in demanding environments for long service life. When tested, our 110 GHz test assemblies maintain low VSWR and insertion loss.

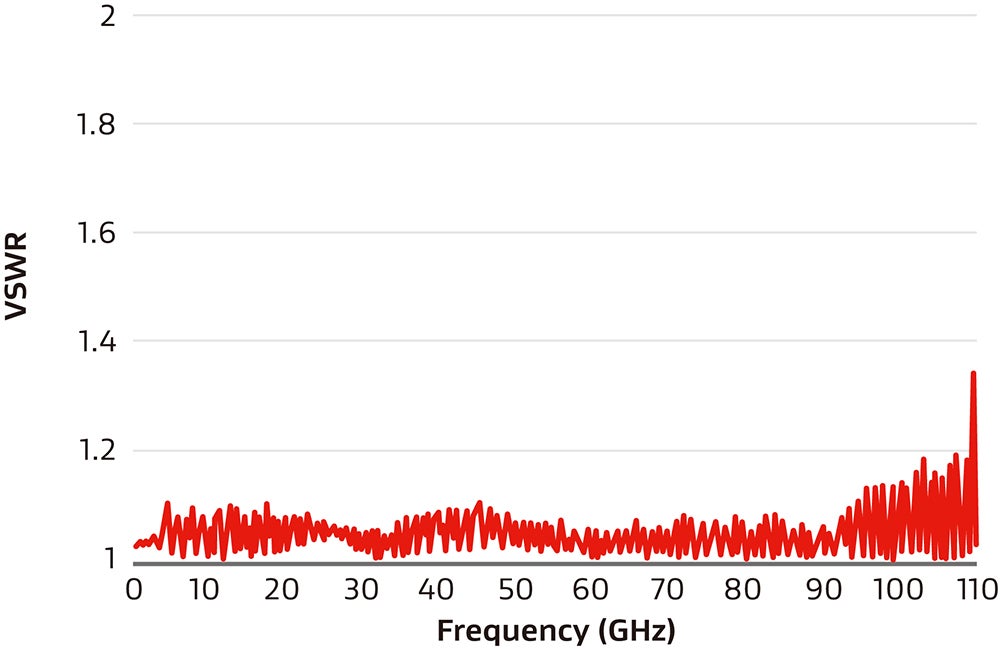

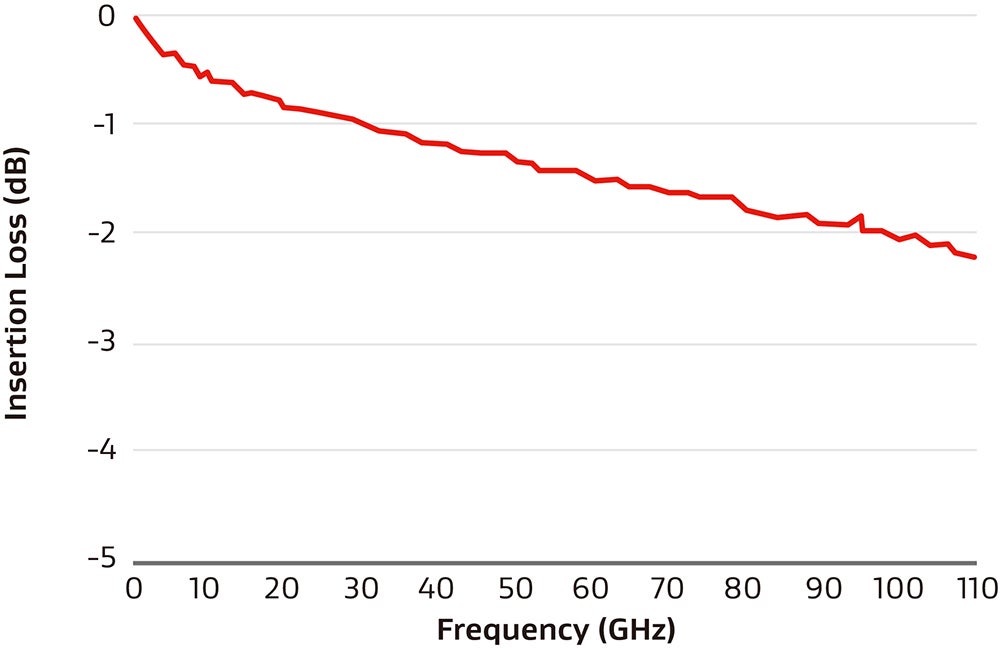

Typical VSWR and Insertion Loss of Gore’s 110 GHz test assemblies based on a 16 cm (6.3 in) assembly length.

Typical VSWR and Insertion Loss of Gore’s 110 GHz test assemblies based on a 16 cm (6.3 in) assembly length.

Applications

GORE PHASEFLEX Microwave/RF Test Assemblies are engineered to perform reliably in a variety of test and measurement applications, including:

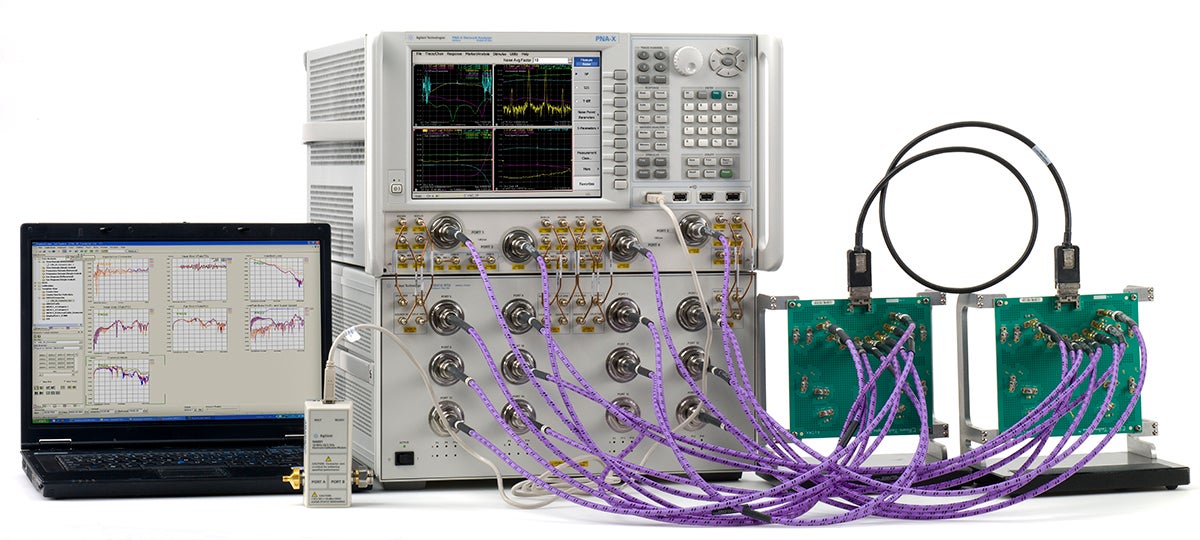

Courtesy, Keysight Technologies, Inc.

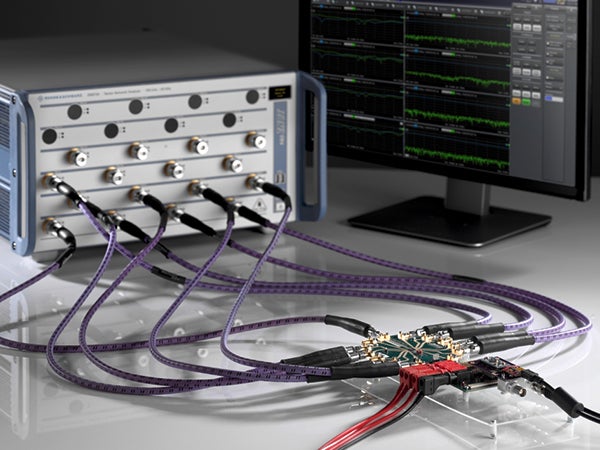

Application on R&S®ZNBT Vector Network Analyzer. Courtesy, Rohde & Schwarz GmbH & Co.

Application on R&S®ZNBT Vector Network Analyzer.

Courtesy, Rohde & Schwarz GmbH & Co.

- anechoic chambers

- antenna ranges

- automated test equipment

- bench-top testing

- electromagnetic compliance testing

- high throughput RF production testing

- nearfield scanners

- portable analyzers

- scalar network analyzers

- test rack systems

- vector network analyzers (VNAs)

- wireless telecommunication module testing

- thermal vacuum chambers

- high speed digital test

- 5G test and interconnection

Features & Benefits

GORE® PHASEFLEX® Microwave/RF Test Assemblies has been recognized among the 2020 Military & Aerospace Electronics Innovators Awards.

- torque, crush and kink resistance

- abrasion resistance

- dust and moisture resistance

- chemical resistance

- wide temperature range

- high connector pull strength

Our test assemblies provide manufacturers with many benefits that improve electrical and mechanical performance such as:

- consistent, repeatable measurements with stable electrical performance up to 110 GHz

- longer service life with durable construction that resists crushing, twisting and kinking

- enhanced phase and amplitude stability with flexure and temperature

- increased throughput and reduced downtime with durable and reliable performance

- a variety of connector options specifically engineered to optimize assembly performance

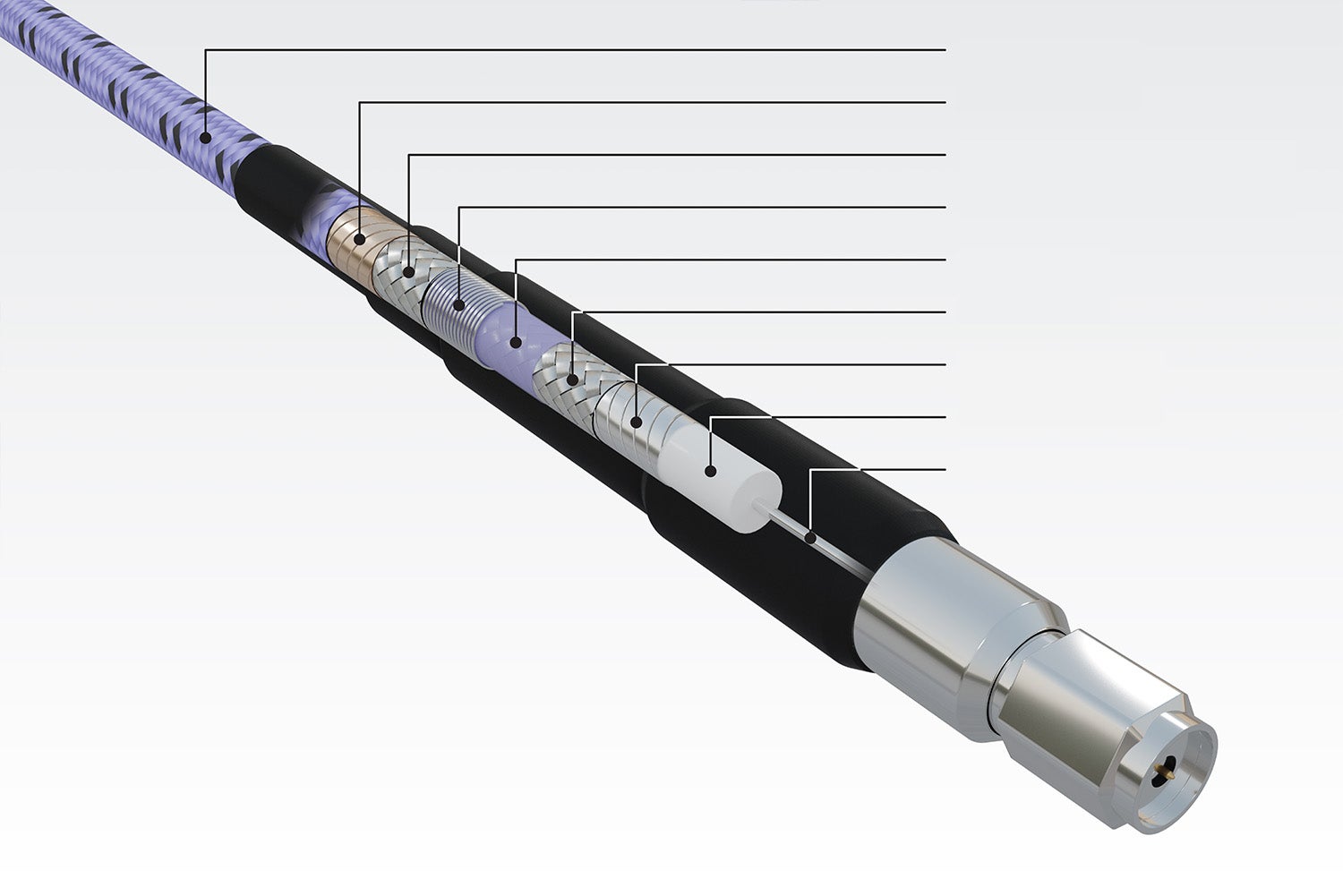

Construction of GORE® PHASEFLEX® Microwave/RF Test Assemblies

Properties

These values demonstrate the electrical, mechanical and environmental performance of our 110 GHz test assemblies.

Electrical

| Gore Cable Type | CX |

|---|---|

| Maximum Frequency (GHz) | 110 |

| Typical VSWR | 1.34:1 |

| Typical Insertion Loss (dB) | 2.14 |

| Impedance (Nominal) (Ohms) | 50 |

| Typical Phase Stability (degree) | ±1.0 |

| Typical Amplitude Stability (dB) | < ±0.05 |

| Dielectric Constant (Nominal) | 1.6866 |

| Velocity of Propagation (Nominal) (%) | 77 |

| Shielding Effectiveness (dB through 18 GHz) | > 100 |

| Time Delay (Nominal) ns/m (ns/ft) | 4.33 (1.32) |

Mechanical and Environmental

| Gore Cable Type | CX |

|---|---|

| Center Conductor | Solid |

| Overall Diameter mm (in) | 4.2 (0.167) |

| Nominal Weight g/m (g/ft) | 55.8 (17) |

| Minimum Bend Radius mm (in) | 10.2 (0.40) |

| Temperature Range (˚C) | -55 to 125 |

| Crush Resistance kgf/cm (lbf/in) | 44.6 (250) |

Related Products

-

GORE Laptop Heat Dissipation for Sustained Peak Performance

-

GORE Universal Pipe Gasket (Style 800)

-

GORE Screw In Series Protective Vents for Solar Energy Systems

-

GORE Insulated Wires For Oil And Gas Downhole Equipment

-

GORE Cable Protection Systems for Civil Aircraft

-

GORE Quad Cables for Defense Aircraft