Gore (日本ゴア)

GORE Protective Vents for Lighting Enclosures

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Protective Vents

Overview of Protective Vents

Better Venting Addresses Lighting Industry Challenges

Lighting enclosures are increasingly vulnerable to the demands of evolving technologies: higher-density components create higher internal temperatures and pressures; transparent lenses make condensation more visible and warranty claims more numerous, and LED bulbs demand longer life of the entire system, requiring more robust protection from both contaminants and condensation.

GORE Protective Vents for outdoor lighting enclosures are proven to reduce condensation and contaminants by:

- providing rapid pressure equalization and release, to extend seal life

- minimizing condensation through more effective vapor diffusion

- preventing entry of contaminants like dust, dirt and debris

- high-performance venting eliminates the need for extra-hardened components, saving weight and costs

GORE® Protective Vents can help your enclosure meet IP and NEMA protection standards.

Why Vent?

Electronic enclosures that are installed outdoors are vulnerable to a wide range of environmental hazards that can affect the performance, reliability and life expectancy of the sensitive electronics within.

Problems for Outdoor Electronics:

Failed Seals

- Pressure differentials are created when a sealed enclosure is exposed to rapid, extreme or recurring changes in ambient conditions.

- Extreme changes in temperature (a sudden thunderstorm on a hot, sunny day), altitude changes (in transit), or the repetitive heating and cooling cycles of internal telecommunications components — any of these can cause a pressure differential within a sealed enclosure.

- A rapid decrease in temperature, for example, can create a vacuum inside the enclosure.

- If this pressure differential is not dissipated, the vacuum places continual stress on the housing seals.

- Over time, this can cause seals to fail, allowing moisture and other contaminants such as dust, dirt and other particulates to be drawn inside, and compromising the functionality of components like telecom air filters, for example.

Pressure differentials are created when a sealed

Condensation

- Moisture can also get inside telecommunication enclosures by diffusion — the process by which vapor moves by natural molecular motion through the walls of a polymer enclosure.

- When water vapor enters a sealed enclosure and has no way to escape, it will condense to a liquid state.

- If this condensation remains inside the sealed enclosure, it can compromise lens function and corrode sensitive electronics and battery contacts used in “hot” telecommunication systems, or those used for network cabinet cooling.

Applications

Proven Experience and Expertise in a Broad Variety of Lighting Applications

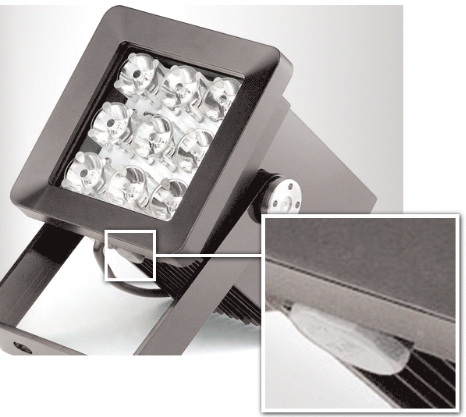

| Industrial / Commercial Outdoor Lighting | |

| Gore has successfully partnered with large manufacturers of industrial and commercial outdoor lights to solve contamination and condensation challenges, and deliver longer lasting lights. | |

| Emergency Lighting | |

| Emergency lighting must be ready to function on a moment’s notice. The global engineering team at Gore has a wealth of applications experience to ensure that emergency lighting is fully functional when needed. | |

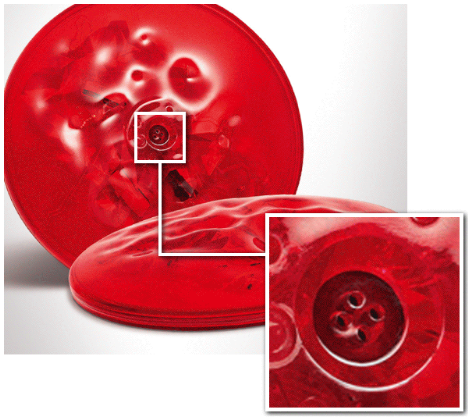

| Outdoor Decorative Lighting | |

| Customers expect decorative lights to maintain their appearance over time. Gore has experience collaborating with outdoor decorative lighting manufacturers to solve condensation issues, which can degrade the appearance of lights. | |

| Entertainment Lighting | |

| With a proven track record in venting entertainment lighting, Gore has helped manufacturers design systems that can withstand harsh environments and reliably provide maximum lighting performance. | |

| Marine Lighting | |

| Marine lighting must be able to withstand water, dirt and debris as well as handle pressure differentials caused by weather changes. Gore’s engineering and materials expertise excels in addressing these challenges. | |

| Ballast and Transformers | |

| Gore has global expertise in solving internal pressure challenges within ballast and transformers. Our team of engineers can be considered an extension of your design team. | |