Gore (日本ゴア)

GORE Screw In Series Protective Vents for Solar Energy Systems

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Screw In Series

Overview of Screw In Series

Venting to Improve Performance, Value and Profit

- Solar energy systems are challenged by the changing demands of evolving technologies, by harsh operating conditions that can threaten performance, and by customer demands for decades-long service life.

- Advanced venting solutions from Gore can help reduce engineering complexity and fabrication costs while maintaining higher system efficiency over the long lifespan customers expect.

GORE Protective Vents for solar system housings are engineered to deliver higher performance over the long term, helping solar systems to do the same. Gore vents:

- provide rapid pressure equalization to ensure the seals maintain the original level of Ingress Protection (IP) rating over the life of the product;

- block ingress of liquids and contaminants like salts, sand, or dust;

- diffuse water vapor more effectively, minimizing condensation damage and improving system power output;

- are available in screw-in, snap-fit or welded membrane styles for easy integration into any housing design;

- are tested and proven to meet the world’s most demanding enclosure-protection standards including Underwriters Laboratory (UL), Technischer Überwachungsverein (TÜV) and International Electrotechnical Commission (IEC).

GORE® Protective Vents can help your enclosure meet IP and NEMA protection standards.

Why Vent?

Electronic enclosures that are installed outdoors are vulnerable to a wide range of environmental hazards that can affect the performance, reliability and life expectancy of the sensitive electronics within.

Problems for Outdoor Electronics:

- Failed Seals

- Pressure differentials are created when a sealed enclosure is exposed to rapid, extreme or recurring changes in ambient conditions. Extreme changes in temperature (a sudden thunderstorm on a hot, sunny day), altitude changes (in transit), or the repetitive heating and cooling cycles of internal telecommunications components — any of these can cause a pressure differential within a sealed enclosure. A rapid decrease in temperature, for example, can create a vacuum inside the enclosure. If this pressure differential is not dissipated, the vacuum places continual stress on the housing seals. Over time, this can cause seals to fail, allowing moisture and other contaminants such as dust, dirt and other particulates to be drawn inside, and compromising the functionality of components like telecom air filters, for example.

GORE® Vents protects seals from stress by continuously equalizing over-pressures or vacuums within

- Condensation

- Moisture can also get inside telecommunication enclosures by diffusion — the process by which vapor moves by natural molecular motion through the walls of a polymer enclosure. When water vapor enters a sealed enclosure and has no way to escape, it will condense to a liquid state. If this condensation remains inside the sealed enclosure, it can compromise lens function and corrode sensitive electronics and battery contacts used in “hot” telecommunication systems, or those used for network cabinet cooling.

Applications

Venting Solutions for a Variety of Solar Applications

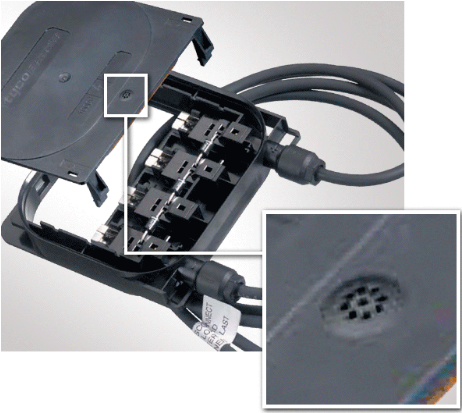

| Junction Box | |

| Water can cause corrosion and shorts to the electronics in junction boxes. By equalizing pressure inside the box, GORE Protective Vents prevent stress on the housing seals, so water cannot enter. | |

| CPV Modules | |

| The large dimensions of the CPV modules make them susceptible to pressure differentials caused by temperature changes. Installing GORE Protective Vents in the housing equalizes pressure and increases efficiency. | |

| String Combiner Box | |

| Regardless of the size and volume of the string combiner box, Gore can customize a venting solution to ensure the reliability of the seals and gaskets, protecting the connectors from shorts caused by water. | |

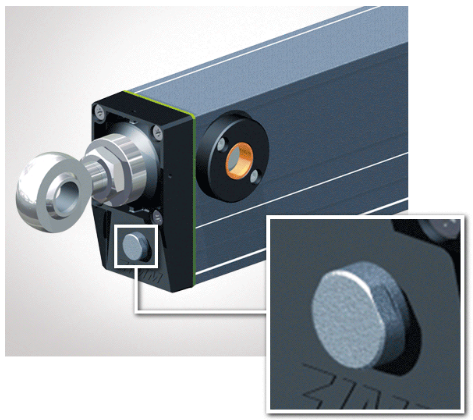

| Tracking Equipment | |

| Exposure to water and other contaminants can compromise the mechanical components of the tracking system. GORE Protective Vents provide a barrier against liquid and other contaminants that can lead to corrosion. | |

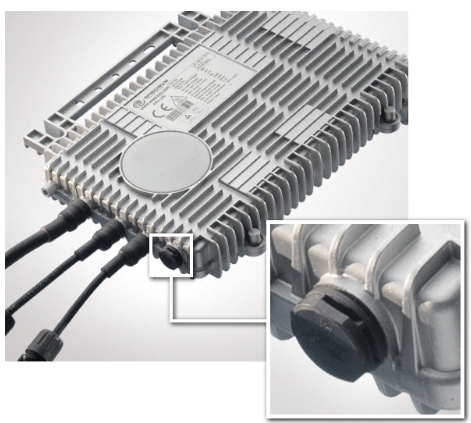

| Micro / String Inverter | |

| Corrosion can quickly damage the sensitive electronics inside the micro/string inverter. GORE Protective Vents prevent degradation by providing a durable barrier against water, oils and other liquids. | |

| Monitoring Equipment | |

| Condensation can compromise the performance of control components. By allowing moisture vapor to diffuse easily, GORE Protective Vents reduce the potential for condensation inside the enclosures. | |

Product Comparison

Adhesive Series

Screw-In Series

Snap-In Series