Gore (日本ゴア)

GORE STA-PURE Flexible Freeze Container

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Flexible Freeze Container

Overview of Flexible Freeze Container

Single-use storage containers have many advantages to biopharmaceutical manufacturers and are commonly used throughout drug production. However, there are vulnerabilities associated with traditional polymer-film-based disposable bags:

- They can become brittle and fragile at cold temperatures, increasing the risk of loss during cold chain handling, transport or storage.

- Extractables and leachables from materials commonly used in disposable packaging are a concern.

Now, Gore Materials Science Delivers a Solution to Both Issues

GORE STA-PURE Flexible Freeze Containers in medium, large and sample sizes. Small 2L size not shown.

Single-use GORE STA-PURE Flexible Freeze Containers are intended for storing and transporting bulk drug substances, after freezing at -86°C (-123°F).

The strength, durability and high purity of the materials of construction make GORE STA-PURE Flexible Freeze Containers ideal for high-value biopharmaceutical bulk drug substances such as:

- vaccines

- monoclonal antibodies

- antibody drug conjugates (ADCs)

Technology

Utilizing our advanced materials understanding, we’ve engineered a highly durable proprietary fluropolymer (PTFE) composite film designed specifically for bulk biopharmaceutical cold chain applications.

- Proven strength and durability at frozen temperatures

- Frozen film integrity maintained after impact and flex cycles

- Frozen Container integrity maintained after multiple freeze/thaw cycles

- High purity, biocompatible fluoropolymer film

- Low extractables profile ideal for bioprocess applications

This distinctive material is combined with a patented* bag design to create robust containers able to withstand the rigors of frozen handling.

* Patent EP3174514, additional patents pending in the US & EU

Product Performance

Gore takes the responsibility of providing products that perform the way we say they will perform seriously. Our comprehensive approach to product testing includes evaluation of performance at the material level and in final product form.

We put our filled containers through a battery of durability tests, including impact testing and multiple freeze thaw cycles, to prove that they will be able to withstand the rigors of frozen transport, handling and storage.

Containers filled with a phosphate-buffered saline solution were frozen in a blast freezer for a minimum of 24 hours with a set point of -86°C (-123°F), or in a plate freezer for a minimum of 4 hours at a set point of -70°C (-94°F). After freezing, the containers were tested for frozen impact durability, performance after five freeze/thaw cycles and after long-term storage.

| Frozen Impact Durability | Frozen and dropped from height of 3 feet (91.4 cm) onto concrete floor |

|---|---|

| Freeze/Thaw | Stored in a freezer and thawed in water bath for 5 cycles |

| Long-Term Frozen Storage | Stored for 12 months |

High Purity and Low Extractables

The materials used in the GORE STA-PURE Freeze Container are durable and, above all, highly pure and suitable to bioprocessing applications. All fluid contact surfaces of the containers (container and port) are made of a proprietary 100% fluoropolymer composite. The container film is chemically inert and has high degree of compatibility with a variety of fluids.

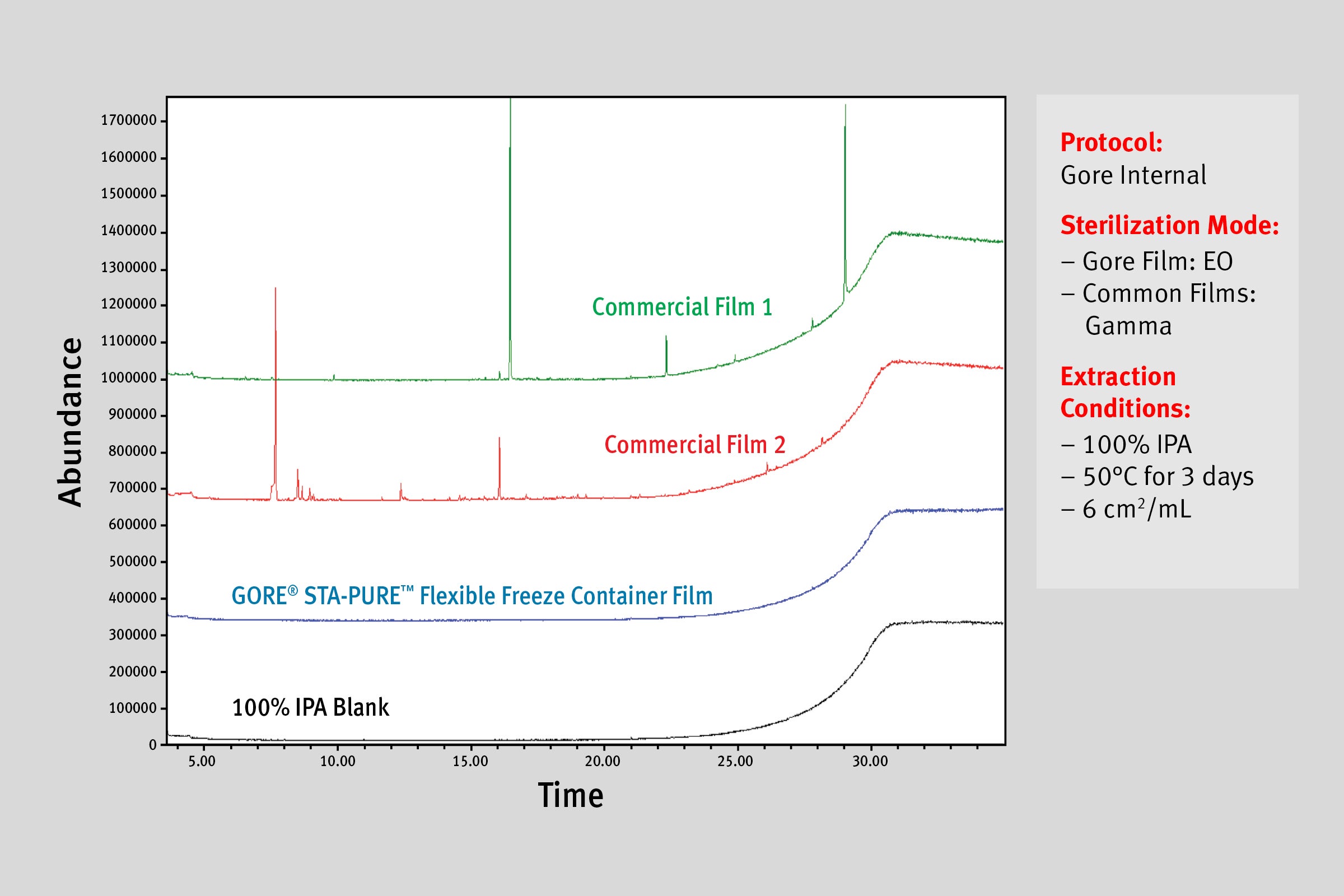

We compared the material in our containers with commonly-used films in traditional single-use bags. Results show that the film material in the GORE STA-PURE Freeze Containers (container and port) have a lower extractables profile compared to other commonly-used films.

Test Details: Following the recommended sterilization protocols for each, a 6cm2/mL sample of Gore film and commonly-used films were tested in 100% IPA at 50°C for 3 days. The impurities were measured using GC/MS.

The extractables data shown is based on Gore’s internal test protocol. In line with industry standards, Gore performed an extractables study based on guidelines put forth by the BioPhorum Operations Group (BPOG) as stated in their User Requirements Pack. This study involved testing representative material sets after sterilization from the GORE STA-PURE Flexible Freeze Container’s product portfolio.

Configurations

GORE STA-PURE Flexible Freeze Containers are sold as an assembly and are suitable for both plate and blast freezers in sample, small, medium and large sizes.

| Size | Dimensions (W x L) | Freezing Method | Maximum Fill Volume |

|---|---|---|---|

| Sample | 5 x 6 in (12.7 x 15.2 cm) | Suitable for plate or blast freezers | 50 milliliter (mL) |

| Small | 8 x 17.5 in (20.3 x 44.5 cm) | plate blast | 2.5 Liter (L) 2.5 Liter (L) |

| Medium | 12 x 18 in (30.5 x 45.2 cm) | plate blast | 4.25 Liter (L) 5.0 Liter (L) |

| Large | 25 x 18 in (63.5 x 45.2 cm) | plate blast | 10 Liter (L) 12 Liter (L) |

Optional hard-shell carriers and barrier wraps are available.

Gore also offers single-use hard-shell carriers (patent pending) made of durable high-density polyethylene (HDPE), configured for use in either blast or plate freezers, as an optional accessories to the Container. They are designed to maximize freezer space, make handling easier and further protect tubing in the Container Assembly.