Gore (日本ゴア)

GORE STA-PURE PCS Series Pump Tubing

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: PCS Series

Overview of PCS Series

Challenging biopharmaceutical processes demand superior solutions. To address these challenges, GORE STA-PURE Pump Tubing, Series PCS, offers unmatched reliability and security against rupture during high-pressure operations. Unlike conventional extruded silicone pump tubing, which may balloon or rupture, Series PCS employs a patented composite structure to ensure consistent performance.Series PCS tubing maintains steady flow rates even at pressures up to 100 psig, making it ideal for rigorous applications in pharmaceutical and biotechnology industries.

| High Flex Durability |

|

|---|---|

| High Resilience |

|

| Standard Sizes |

|

| Compatible with CIP/SIP and Autoclave Sterilization |

|

Product Information of PCS Series

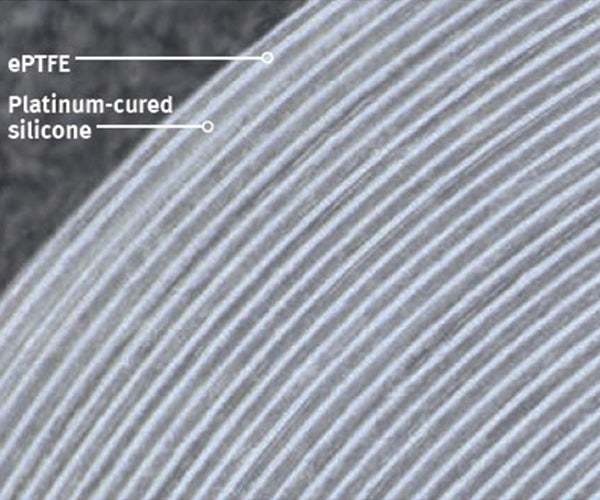

Unlike conventional tubing, Series PCS is manufactured with a patented composite of platinum-cured silicone rubber, reinforced with expanded polytetrafluoroethylene (ePTFE) for added strength and resilience. Shown: Cross-section of tube wall in detail.

Materials of Construction

We designed Series PCS with a patented composite material that combines expanded polytetrafluoroethylene and platinum-cured silicone. This unique construction enhances durability and flexibility for demanding environments.

Performance Testing

Gore rigorously tested Series PCS tubing under real-world conditions to ensure durability. We subjected the tubing to peristaltic pumps operating at pressures up to 100 psig and exposed it to multiple cleaning and sterilization cycles. These tests demonstrated consistent performance across a wide range of discharge pressures.

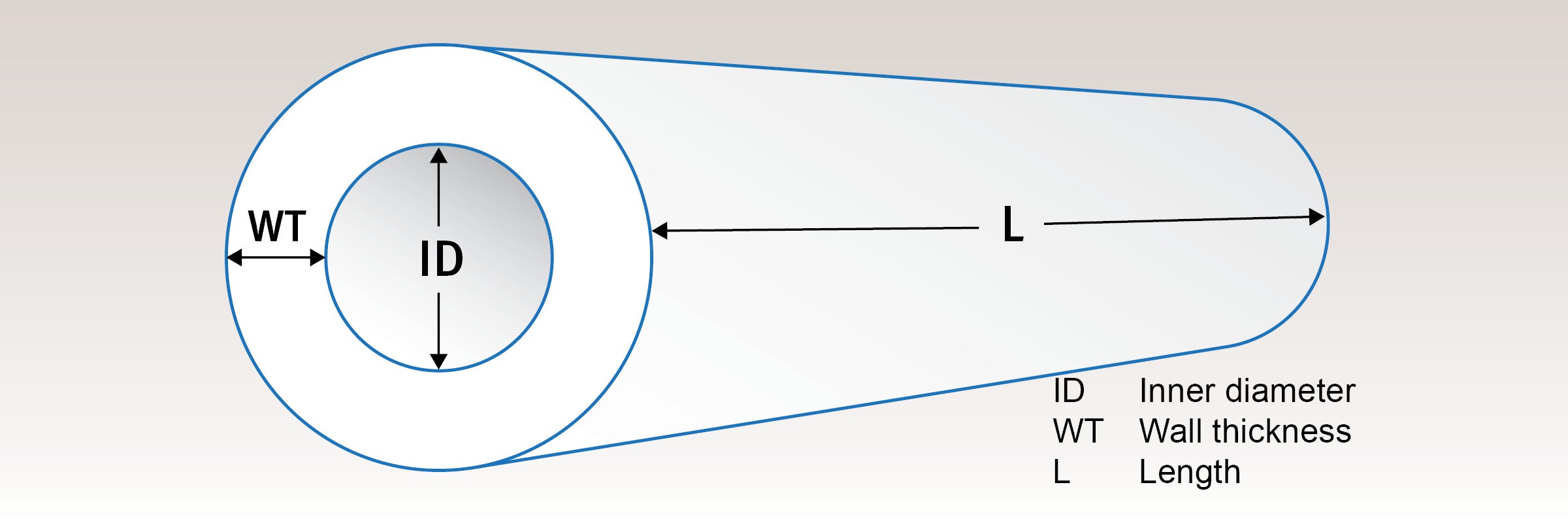

Manufacturing Environment and Quality

Our team manufactures Series PCS in an ISO 14644-1 Class 7 cleanroom and strictly adheres to cGMP guidelines outlined in Gore PharmBIO Products’ certified quality system (ISO 13485 and ISO 15378). We visually inspect each product for defects and measure its inner diameter, wall thickness, and length to confirm they meet specifications.

Results Summary: Series PCS Tube Life and Flow Decay at End of Testa

| Discharge Pressure (psig) | Tube Life (hours) |

|---|---|

| 10 | >2,160b |

| 100 | 106 ± 48c |

a Continuous pumping of room temperature deionized water in Watson-Marlow 500 Series peristaltic pumps, with pump head speed of 220 rpm (two rollers). Samples selected represent the worst-case configuration of pump and tube size based on mechanical stresses imposed by the pump on the tube.

b Tube size = 9.5 mm (ID) x 2.4 mm (WT). When testing was terminated at 2,160 hours, all 6 samples were performing without failure. Failure is defined as rupture, leakage, sustained flow reduction of 25 percent or more, or inability to sustain operating pressure. Tubing was subjected to conditions similar to 5 CIP/SIP cycles (3 cycles before testing and 2 cycles during testing).

c Tube size = 3.2 mm (ID) x 2.4 mm (WT). Six tubing samples were tested until failure as defined in (b) above. The operating life until failure is presented as the average and standard deviation for all samples. The minimum observed value was 52 hours. Before testing, tubing was subjected to conditions similar to 1 CIP/SIP cycle.

Biocompatibility Testing*

GORE STA-PURE Pump Tubing, Series PCS meets the following requirements:

| Biological Testing | USP ‹87› Biological Reactivity Tests In Vitro |

|---|---|

| USP ‹88› Biological Reactivity Tests In Vivo, Class VI |

*Results are verified annually.

Manufacturing Environment and Quality

We manufacture Series PCS in an ISO 14644-1 Class 7 cleanroom and strictly adhere to cGMP guidelines defined by Gore PharmBIO Products’ certified quality system (ISO 13485 and ISO 15378). Our team visually inspects each product for defects and measures the inner diameter, wall thickness, and length of the tubing to ensure they meet specifications.

Storage and Shelf Life

You can rely on Series PCS tubing for up to four years, thanks to its validated shelf life. To maintain its quality, store the product in its original packaging at room temperature.

Sterilization Methods

We validate Series PCS tubing for steam-in-place (SIP), clean-in-place (CIP), and autoclave sterilization. To avoid damage or degradation, refrain from using gamma or electron beam irradiation methods.

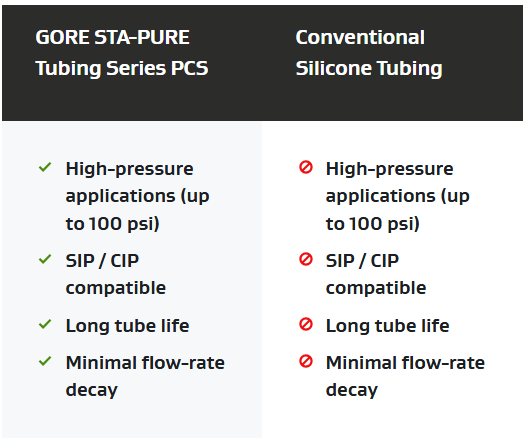

Product Comparison

Pharmaceutical and biotechnology manufacturers often avoid peristaltic pumps due to the durability issues of silicone tubing. Series PCS resolves these limitations, delivering superior performance under rigorous conditions. Compared to silicone, Series PCS offers extended durability and reliability after multiple sterilization cycles.

Long-term Reliability

Tests demonstrate the significant performance advantages of using Series PCS pump tubing rather than silicone in long-duration applications. This series dramatically outperforms silicone in terms of both flow-rate decay and extended service life.

Series PCS Outperforms Silicone Tubing While Lasting At Least 70 Times Longer

– Series PCS did not fail; testing was terminated at 2,160 hours. – Silicone tubing failed within 29 hours.

Test Conditions

Gore tested Series PCS tubing with Watson-Marlow 500 Series peristaltic pumps. The team set up continuous pumping of room-temperature water at 10 psig and ran the pumps at a speed of 220 rpm (two rollers). They subjected the Series PCS tubing (9.5 mm inner diameter x 2.4 mm wall thickness) to five SIP/CIP cycles, showcasing its outstanding durability. In contrast, the silicone tubing did not undergo the same testing conditions.

Dimensions & Availability of PCS Series

| Example | Z | A | 12 | ME |

|---|---|---|---|---|

| Attribute | Inner diameter (ID) | Wall thickness (WT) | Length (L) | Series PCS |

| Nominal Range | 1.6 – 25.4 mm (0.063 – 1.0 in) | 0.8 – 9.0 mm (0.031 – 0.354 in) | 304.8 – 796.0 mm (12.0 – 31.3 in) | ME |

| Example: ZA12ME is a Series PCS tube with a nominal ID of 3.2 mm (0.13 in), WT of 1.6 mm (0.063 in), and L of 304.8mm (12 in). | ||||

Related Products

-

GORE Microwave/RF Assemblies 7 Series for Defense Land Systems

-

GORE Protective Vents for Lighting Enclosures

-

GORE High-Frequency Cable Assemblies for Ka Band Frequencies

-

GORE CAN Bus Cables for Defense Aircraft

-

GORE Space Cables, Type SPC For GEO Applications

-

GORE Acoustic Vents for Automotive Applications