Gore (日本ゴア)

Gore Technology for Innovative Flue Gas Desulphurization (FGD)

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Flue Gas Desulphurization

Overview of Flue Gas Desulphurization

The GORE SO2 Control System is a flue gas desulphurization system (FGD) which allows plants to comply with SO2 emission standards without requiring any reagent. The system utilizes fixed catalysts to convert SO2 into saleable sulfuric acid. This eliminates concerns related to reagent supply, logistics, handling, storage and preparation operations, reagent price volatility and solid waste disposal. Since the Gore System is installed after an existing ESP or baghouse there is no impact on the fly ash, allowing for its continued beneficial use.

Benefits of Gore’s FGD system

No reagent, small footprint, simple operation, low operating cost – the GORE SO2 Control System for flue gas desulphurization allows you to reap multiple benefits.

Low Operating Cost

- No reagent required for SO2 removal

- Low parasitic power consumption

- Revenue from sulfuric acid byproduct sales

- Simple operation

Low Process Impact

- Small, flexible footprint

- No impact on fly ash quality

- Additional PM reduction

- Minimal maintenance required

- No additional CO2 generation

The science behind the solution

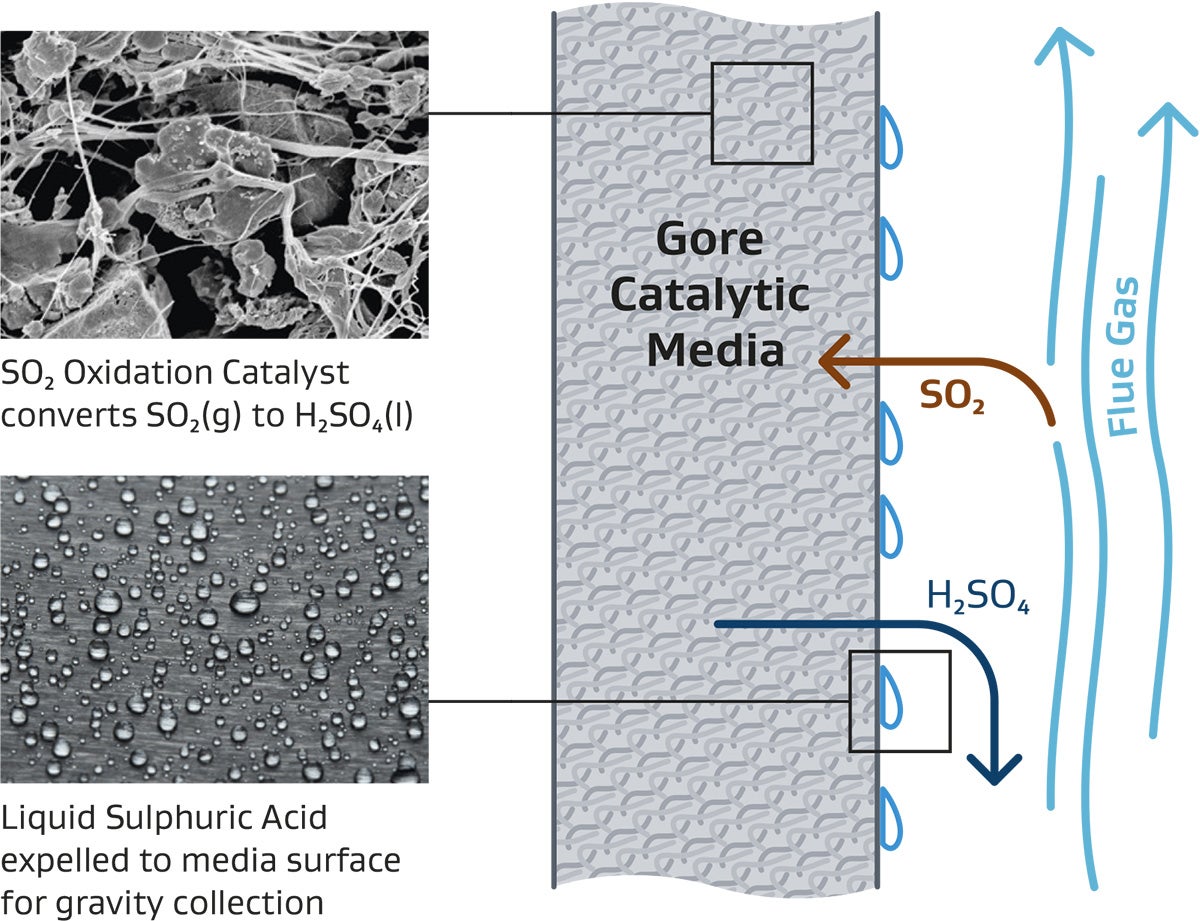

How GORE SO2 Control Modules work

Sorbent Polymer Catalyst (SPC) composite material is a novel fluoropolymer-based substance created by Gore scientists. This substance’s sorbent effectively captures both elemental and oxidized mercury from the flue gas stream. As a result, it is unaffected by modifications to fuel or manufacturing processes that alter mercury speciation. Through chemisorption, mercury is tightly bound inside the SPC. It is a highly successful solution for high sulfur coals or units with SO3 gas conditioning because, unlike many activated carbon sorbents, the presence of SO3 does not prevent mercury extraction by the SPC. Since no injected sorbents are used, there is no need to worry about fly ash contamination or additional particulate matter collection. Additionally, the technology eliminates the need for chemicals for oxidation, thus avoiding concerns over halogen-induced corrosion and wastewater treatment complications.

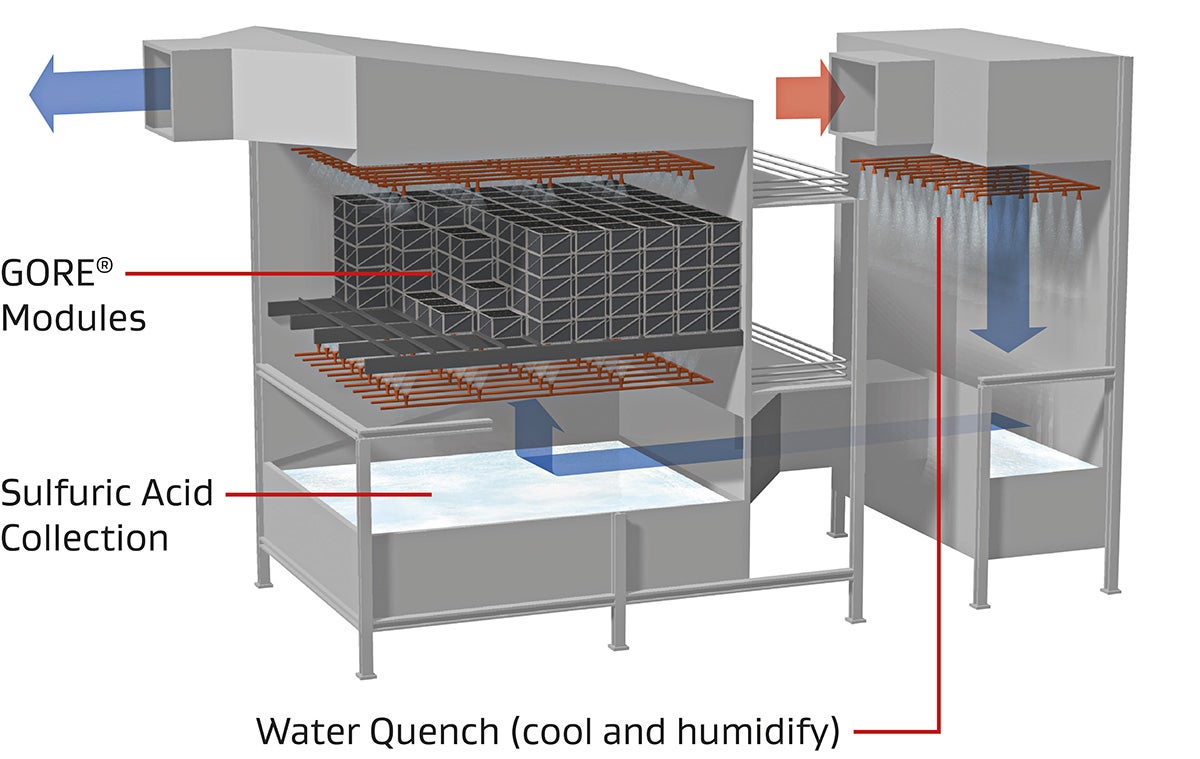

GORE SO2 Control System including water quench, catalytic modules & acid collection

The lack of reagent and low parasitic power enables a significantly lower operating cost than other Flue Gas Desulphurization (FGD) systems. Moreover, the footprint of the system has significant flexibility allowing it to fit into space constrained sites that are challenging for wet and semi-dry systems. Since water is recovered in the sulfuric acid concentration step, the overall water consumption is lower than with a wet limestone FGD system. The passive system operation is simple and doesn’t require any adjustments, treatments, or regeneration. The catalytic SPC modules have no moving parts and will continuously convert SO2 into sulfuric acid with the lowest total cost of ownership.

The sulfuric acid byproduct is a versatile chemical with strong demand in the fertilizer production industry. Unlike limestone-based FGD systems, which release CO2 as part of the chemical reaction involved in capturing SO2, the GORE SO2 Control System’s catalytic reaction does not release CO2.