Gore (日本ゴア)

GORE Universal Pipe Gasket (Style 800)

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: Universal Pipe

Overview of Universal Pipe

Achieving a durable, reliable seal across a range of pipeline applications can be a “multiple-choice” challenge: accommodating diverse flange materials, process media and operating conditions can involve a large inventory of multiple pipe flange gasket types. But it doesn’t have to. Because Gore offers a universal pipe seal that meets all these challenges!

SEALING CHALLENGES FOR PIPE FLANGE GASKETS

- Multiple piping / flange materials

- Aggressive media

- Deviations in flanges / sealing surfaces

- Alternating system pressures

- High temperatures / thermal cycling

THE GORE SOLUTION: A UNIVERSAL PIPE GASKET SEAL

GORE Universal Pipe Gasket (Style 800) provides a reliable seal for steel, glass-lined steel (GLS) and fiber-reinforced plastic (FRP) flanges. These Gore piping gaskets withstand the full spectrum of strong acid, alkali, and solvent process media, as well as the most challenging application conditions including thermal cycling and elevated temperatures. These highly conformable 100% ePTFE gaskets for flanges reliably seal irregular surfaces.

And, having a single pipeline gasket solution for multiple flange materials can reduce the chance of someone installing the wrong pipe flange gasket material — which could threaten process safety and risk production downtime.

It’s easy to choose the right gasket for each flange gasket size: critical identifiers are clearly printed on every genuine GORE Universal Pipe Gasket (Style 800).

WHAT STANDARDS COVER PIPE GASKETS?

Gore offers a broad range of ring and full-face gaskets dimensioned for the major industry standards; ASME, EN and JIS.

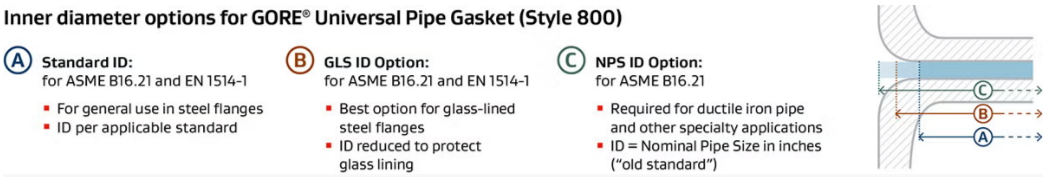

Within these pipe gasket sizes, we also offer a section of ID options:

- Standard ID

- GLS ID: optimized for GLS flanges

- NPS ID: Nominal Pipe Size (Old Standard) for ductile iron and other specialty applications

GORE Universal Pipe Gasket (Style 800) is versatile enough to seal a wide range of flange materials, and our extensive portfolio makes it easy to get the exact style, size and ID option that’s right for your application.

Applications

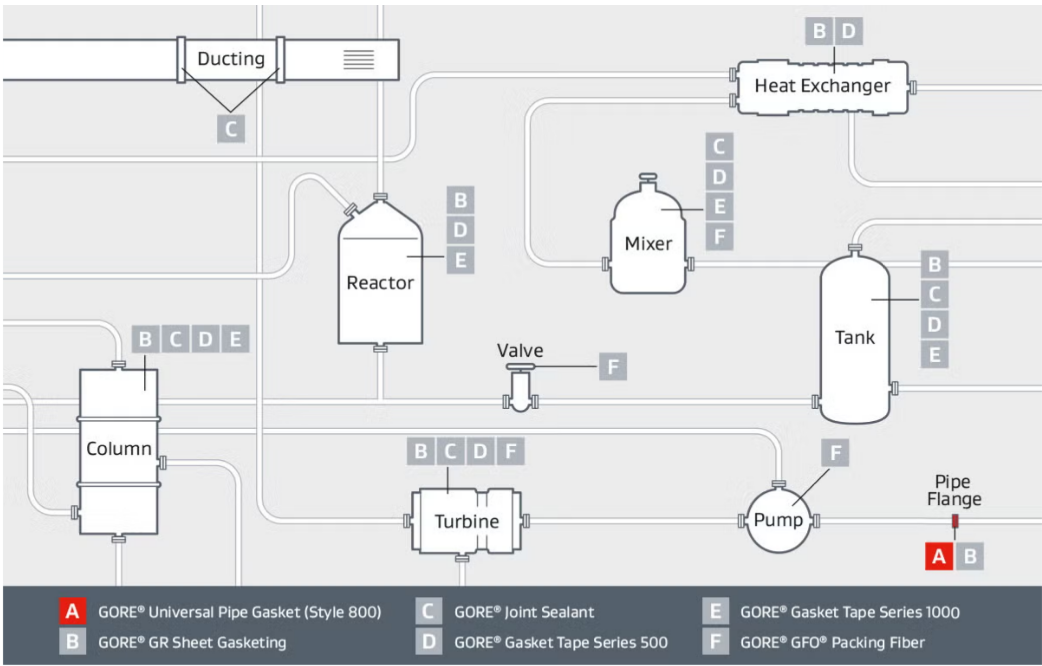

GORE Universal Pipe Gasket (Style 800) offers a unified material solution for sealing a wide range of flange materials in a wide range of processes and industries.

Processes involving highly-aggressive media or thermal cycling, as in:

- Chemical processing

- Pulp and paper manufacturing

- Mining and minerals

- Semiconductor manufacturing

- Power generation

Requirements that challenge other non-metallic flat gaskets, such as:

- Exhaust-flange sealant

- High-pressure flange sealant

- High-temperature flange sealant

- Flange gasket for sulfuric acid and many other highly aggressive media

Equipment flanges of steel, glass-lined steel (GLS), and fiber-reinforced plastic (FRP) used in:

- Pipes

- Manways

APPLICATIONS FOR GORE UNIVERSAL PIPE GASKET (STYLE 800)

GORE® Universal Pipe Gasket (Style 800) performs durably across a range of challenging applications, reliably sealing steel, glass-lined steel (GLS) and fiber-reinforced plastic (FRP) flanges

Performance Benefits

Proprietary, patented technology

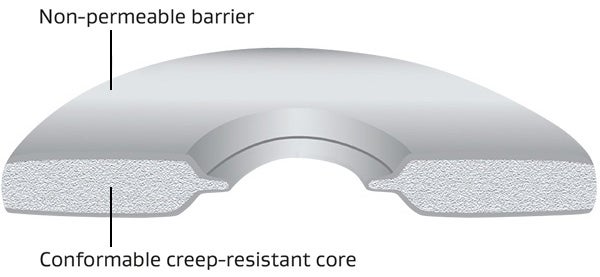

GORE Universal Pipe Gasket (Style 800) uniquely combines two patented construction elements, each made of 100% expanded PTFE (ePTFE).

A non-permeable barrier layer covers the inside diameter and gasket flange faces. This creates a tight seal at low gasket stress and protects the flange surfaces.

A conformable-yet-strong interior provides superior resistance to creep and cold flow.

The patented construction of GORE Universal Pipe Gasket (Style 800) creates a tight initial seal and maintains a reliable long-term seal.

GORE COMBINES PREMIUM PERFORMANCE WITH GREATER VERSATILITY

Long-term reliable sealing

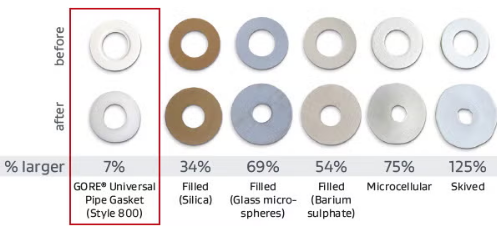

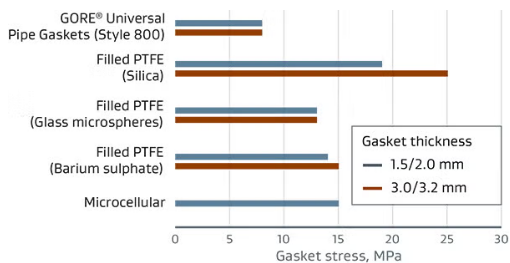

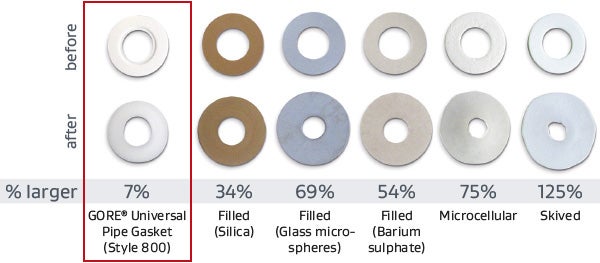

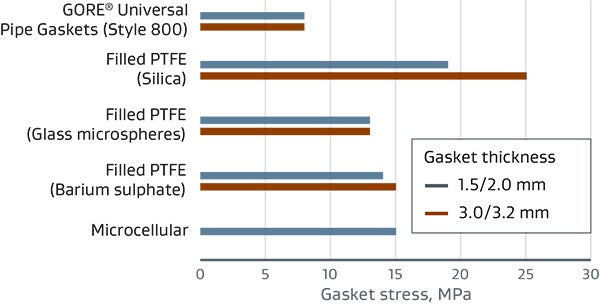

Unlike conventional (filled and skived) PTFE pipe gaskets, Gore’s expanded PTFE gaskets are highly conformable to common flange imperfections, creating a tight seal in challenging conditions.

With superior resistance to creep and cold flow, GORE Universal Pipe Gasket (Style 800) retains its dimensional stability through thermal and pressure cycles. This avoids gasket intrusion into the bore, and maintains bolt load, enabling a long-term reliable pipe seal.

GORE Universal Pipe Gasket’s superior creep resistance outperforms other non-metallic flat gaskets made of ordinary PTFE. (Tested at 34.5 MPa (5000 psi) load, 230 °C (446 °F) for 15 minutes.)

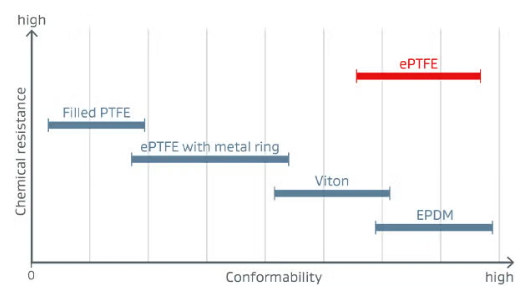

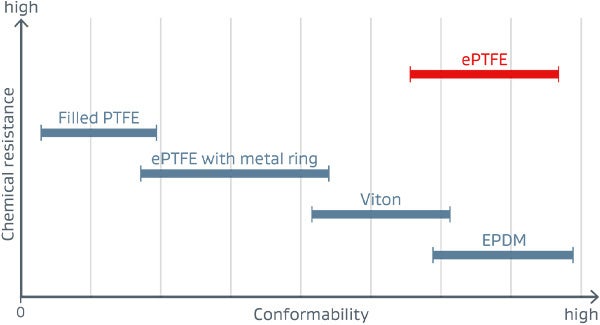

Chemical resistance + conformability outperforms other gasketing

Only GORE Universal Pipe Gasket (Style 800) offers this unique combination of chemical resistance and conformability. That’s why its performance as a pipe flange seal is unmatched by other gasketing materials.

- Chemically inert to virtually all acids, alkalis and solvents, except elemental fluorine and molten alkali metals.

- Highly conformable, to effectively seal even old, imperfect flange surfaces without the cost and downtime of re-surfacing.

- Creates a reliable seal that starts, and remains, leak-tight.

Gore’s combination of exceptional chemical resistance and exceptional conformability outperforms other gasketing materials.

One gasket, many applications

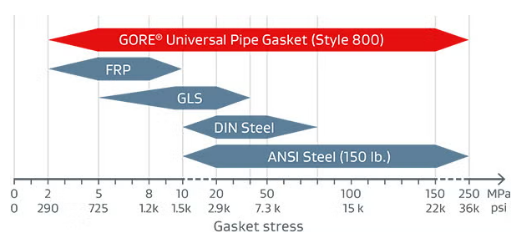

GORE Universal Pipe Gasket (Style 800) creates a tight, reliable seal for multiple flange materials, so it can replace multiple other pipe flange gasket materials in virtually any application that requires excellent resistance to aggressive chemicals, high pressures or high temperatures.

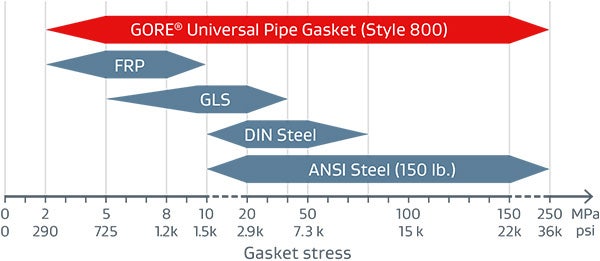

Our patented technologies deliver a low stress-to-seal capability that is ideally suited for glass-lined steel pipe and FRP piping systems, while maintaining the material strength required for outstanding performance in steel systems.

Using GORE Universal Pipe Gasket (Style 800) across multiple pipe flange materials and process media can:

- Streamline gasket ordering and inventories.

- Standardize gasket selection and installation processes.

- Reduce the risk of choosing the “wrong” pipe gasket material, which could create process safety and downtime issues.

GORE Universal Pipe Gasket (Style 800) reliably seals across the full range of flange stresses.

More gas-tight, for reduced emissions

In processes with elevated temperatures, GORE Universal Pipe Gasket (Style 800) is significantly more gas-tight than other non-metallic pipe flange seals.

Compared to other gasketing materials, GORE Universal Pipe Gasket (Style 800) is more gas-tight, providing greater leak resistance at higher temperatures.

Related Products

-

GORE Pair Thermal Insulation With Graphite for Better Heat Spreading

-

GORE Type SPM Space Cables For LEO Applications

-

GORE Insulated Wires For Oil And Gas Downhole Equipment

-

GORE SPP Type For High-Current Applications

-

GORE Microfiltration Media for Non-Implantable Medical Devices and In Vitro Diagnostics

-

GORE USB Cables for Civil Aircraft