Gore (日本ゴア)

GORE USB Cables for Defense Land Systems

Manufacturer: Gore (日本ゴア)

Made in Japan

Model: USB Cables

Overview of USB Cables

The success of every military ground mission depends greatly on soldiers receiving critical information immediately without any signal or data glitches. They must also charge their portable devices as fast as possible without interruptions.

Meeting 2.0, 3.0 and 3.1 protocols, GORE USB Cables offer non-stop signal transmission up to 10 Gb/s without interruptions. They make sure high volumes of data and video are uploaded and downloaded instantly, so ground forces get real-time Intel. All versions of our cable bundles also support the latest power management systems so soldiers can comfortably charge carry-on devices quickly, easily and without delay.

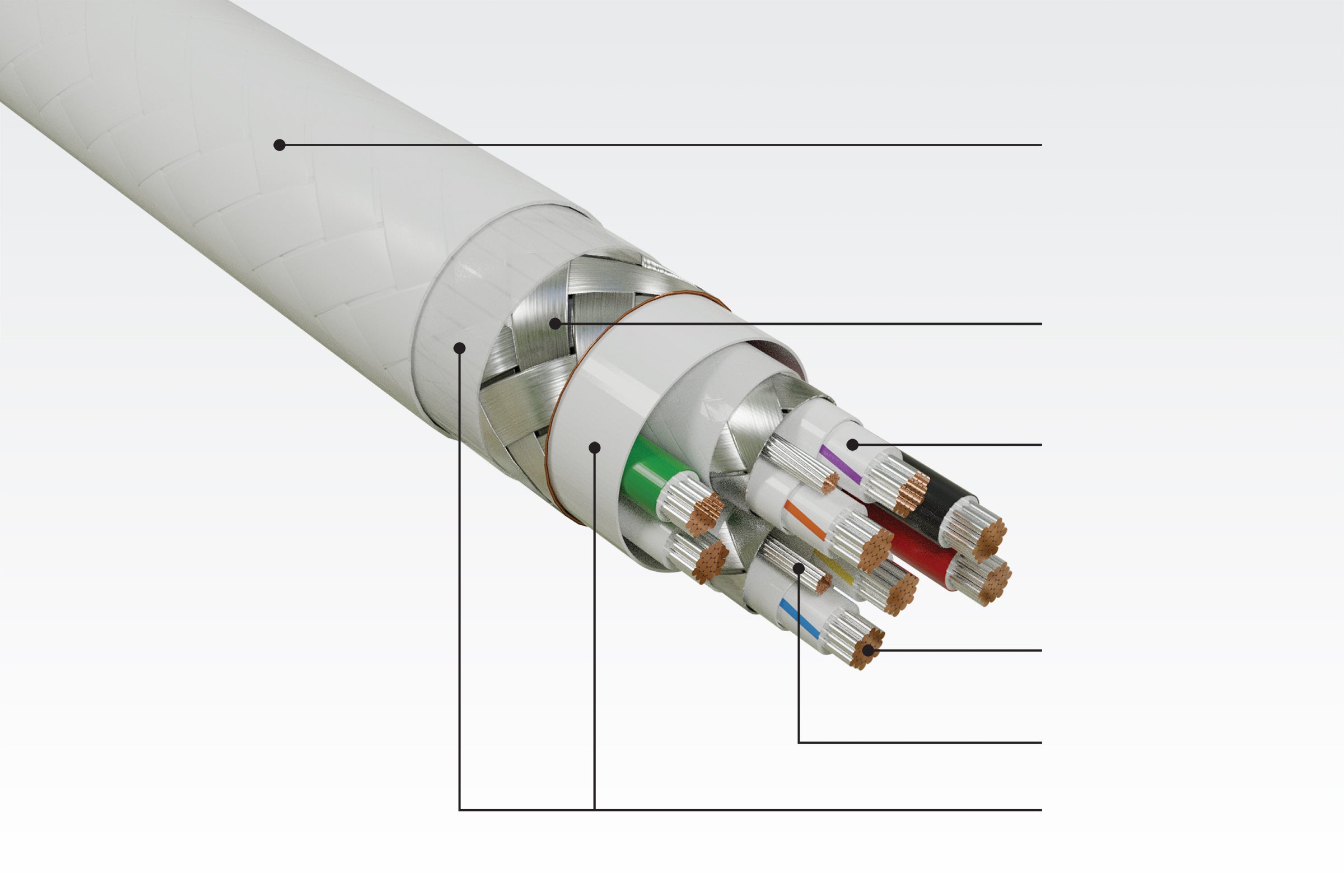

LIFETIME MECHANICAL PROTECTION

The battlefield can be extremely challenging for power and data cables, exposing them and sensitive components to grueling conditions. For added protection, we manufacture our cable bundles with engineered fluoropolymer materials proven to deliver a lifetime of service. They can easily tolerate the most harmful conditions, like extreme temperatures, abrasion, chemicals and more

You can trust that sturdy GORE USB Cables will perform without failure and last long after the alternatives have surrendered to harsh environments.

Sturdy bundle design of GORE USB Cables.

Applications

Meeting the latest protocols, GORE USB Cables deliver trustworthy results in a variety of high power and high data rate transmission applications, like:

- content loading

- data transfer

- HD streaming video systems

- peripheral/sensor networking

- portable electronic devices

- power remote devices

- soldier systems

- vehicle/dismount connectivity

Our military cables can also be terminated with a variety of high-speed connector systems and backshells such as ARINC and MIL-STD-38999 with size 8 contacts.

Features & Benefits

We engineer GORE USB Cables with sturdy features that make them resistant to challenging environmental factors, maintenance activities and operational conditions, including:

- chemically inert materials

- temperature-resistant materials

- abrasion-resistant materials

To system architects and engineers, these cable bundles deliver numerous benefits that ensure their overall performance in defense vehicles, like:

- meet 2.0, 3.0 & 3.1 high data rate protocol requirements

- nonstop signals for data and video transmission up to 10 Gb/s

- instant high-volume content uploads and downloads

- charge carry-on devices quickly and easily without delays

- lifetime protection against grueling land and in-vehicle conditions

- compatible with a variety of high-speed connector systems and backshells

Technical Specs & Drawings

These values demonstrate the electrical, mechanical and environmental performance of GORE USB Cables for defense land systems. Download our data sheet for more cable characteristics, qualifications and part numbers. Also, fill out a short form for instant access to drawings.

| Elec./Mech./Environ. Property | Value |

|---|---|

| Signal Transmission Speed Gb/s | Up to 10 |

| Standard Impedance Ohms High-Speed Pairs Low-Speed Pair | 90 ± 5 90 ± 10 |

| Typical Operating Voltage V | < 15 |

| Nominal Velocity of Propagation % | 80 |

| Nominal Time Delay ns/m (ns/ft) | 4.07 (1.24) |

| Capacitance pF/m (pF/ft) | 50.0 (15.2) |

| Maximum Skew Within Paira ps/m (ps/ft) | 15.0 (4.6) |

| Dielectric Withstanding Voltage Vrms Conductor-to-Conductor Conductor-to-Shield | 1500 1000 |

| Jacket Materialb | Engineered Fluoropolymer |

| Jacket Color | White (Laser Markable) |

| Conductor | Silver-Plated Copper Alloy |

| Conductor Color-Coding | High Speed Pairs: Blue/White, Yellow/White, Orange/White, Violet/White Low-Speed Pair: Green/White Power Pair: Black/Red |

| Dielectric Material | Expanded PTFE/PTFE |

| Temperature Range °C | -65 to +200 |

a Shielded twisted pairs only

b Gore’s 3.0 version, part number GSC-01-85201-VG includes a PU halogen-free jacket.

Related Products

-

GORE Protective Vents Screw-In Series Help Outdoor Electronic Devices to Withstand All Weather Conditions And Temperature Changes

-

GORE Rastex Weaving Yarn for Filtration Applications

-

GORE Protein Capture Devices with Protein A

-

GORE PHASEFLEX Microwave/RF Test Assemblies

-

GORE HDMI Cables for Civil Aircraft

-

GORE Ozonation Modules for Semiconductor & Microelectronics Processing