Bolt & Nut, Hard Lock Nut

HardLock-Nut HLN-R/HLN-B

Manufacturer: HARDLOCK

Product made in Japan

Model: HLN-R/HLN-B : M6,M8,M10,M12,M14,M16,M18,M20,M22,M24,M27,M30,M33,M36,M39,M42,M45,M48,M52,M56,M64

HARDLOCK Nut provides self locking performance even in the environments

Play will lead to not only shortened life span but also bolt brakeage which can result in catastrophic accidents.

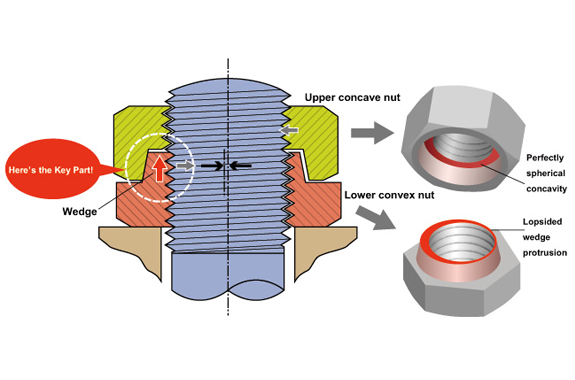

We hit on the idea of utilizing the wedge principle, widely used in ancient Japanese architecture.

Thanks to its principle-inspired design, HLN eliminates thread play completely and outlasts any other nuts in the world when it comes to withstanding severe vibrations.

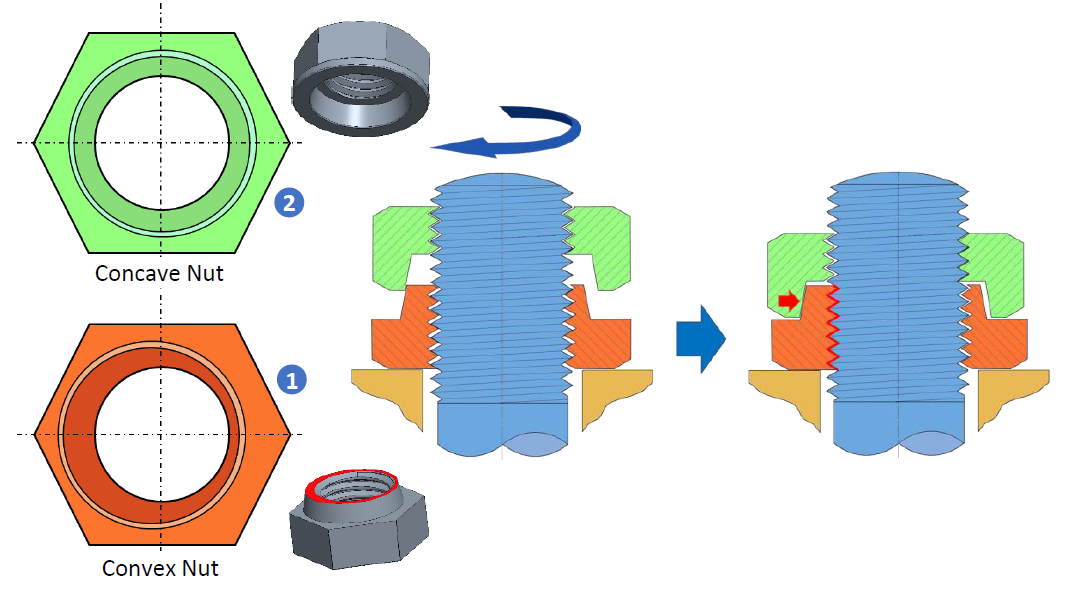

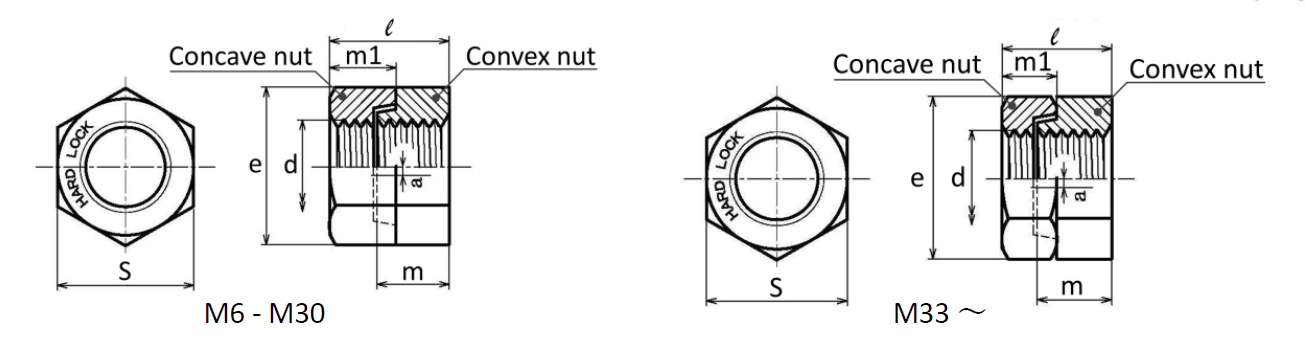

HLN comprises two nuts: the first, “Convex Nut” or clamping nut, features an eccentric protrusion on its upper surface. When you tighten the Concave Nut onto the Convex Nut, it exerts a robust perpendicular load on the bolt from both sides, effectively securing the HLN and providing resistance to vibrations and impacts from any direction.

After installing HLN you will realize a significant decrease in maintenance related work due to its exceptional self locking effect.

This will offer improvement of running cost, though HLN is a high end product, in combination with the advantage that it can be reused multiple times without almost any decrease in performance.

HLN consists solely of metal, unlike typical self-locking nuts, and comes in a variety of materials and surface treatments suitable for any environment.

HLN is predominantly used in applications which require safety at higher level in extreme conditions and environments, including but not limited to; Railway, Mining, Civil engineering and Machinery, just to name a few.

HARDLOCK NUT INSTALLATION

- Use a tightening tool (spanner, torque wrench etc.) to tighten

the Convex Nut to the appropriate torque for the application The convex nut has the same strength class as a regular

hexagon nut and can therefore be tightened to its maximum

limit. - Install the Concave nut onto the Convex nut manually by hand until it no longer turns (in other words, until prevailing torque is generated).

- Make sure that there is a gap of more than 1 thread pitch between the nuts.

If the gap is less than 1 pitch, there may be a chance that sufficient locking effect will not be produced so please refrain from using HARDLOCK NUT with the bolt.

(The same conditions apply for reuse.) - Use a torque wrench to tighten the Concave nut with the recommended torque set by HARDLOCK Industry Co., Ltd

Even after correctly tightening the Concave nut with the torque within the range of recommended tightening torque, there may remain a gap between the nuts due to the tolerance of bolt diameter.

Even in this condition, sufficient locking effect is secured but the Concave nut can be further tightened to come into one sided contact or full contact even with more torque than the recommended torque to better ensure locking effec. - If it is difficult to manage the tightening torque of the Concave nut, please use “one sided contact” as a guide for ensuring locking power.

- When tightening the Concave nut on to the Convex nut, one side of the nuts will first come into contact, which gives an indication of sufficient locking effect (The Concave nut will slightly incline after the contact between the protrusion and the recess.).

- When one sided contact is achieved, the tightening torque rapidly increases. By applying additional torque , the nuts will come into full contact .

- This state produces the ultimate locking effect of the HARDLOCK NUT, but further tightening may cause the breakage of bolt threads. It is recommended to stop tightening the concave nut when the nuts come into full contact even though the applying torque is less than the maximum of recommended tightening torque.

- Use a tightening tool (spanner, torque wrench etc.) to tighten

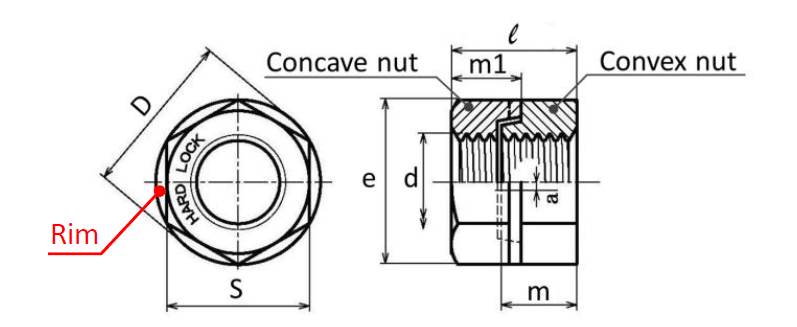

HARDLOCK NUT Standard Rim Type (HLN-R)

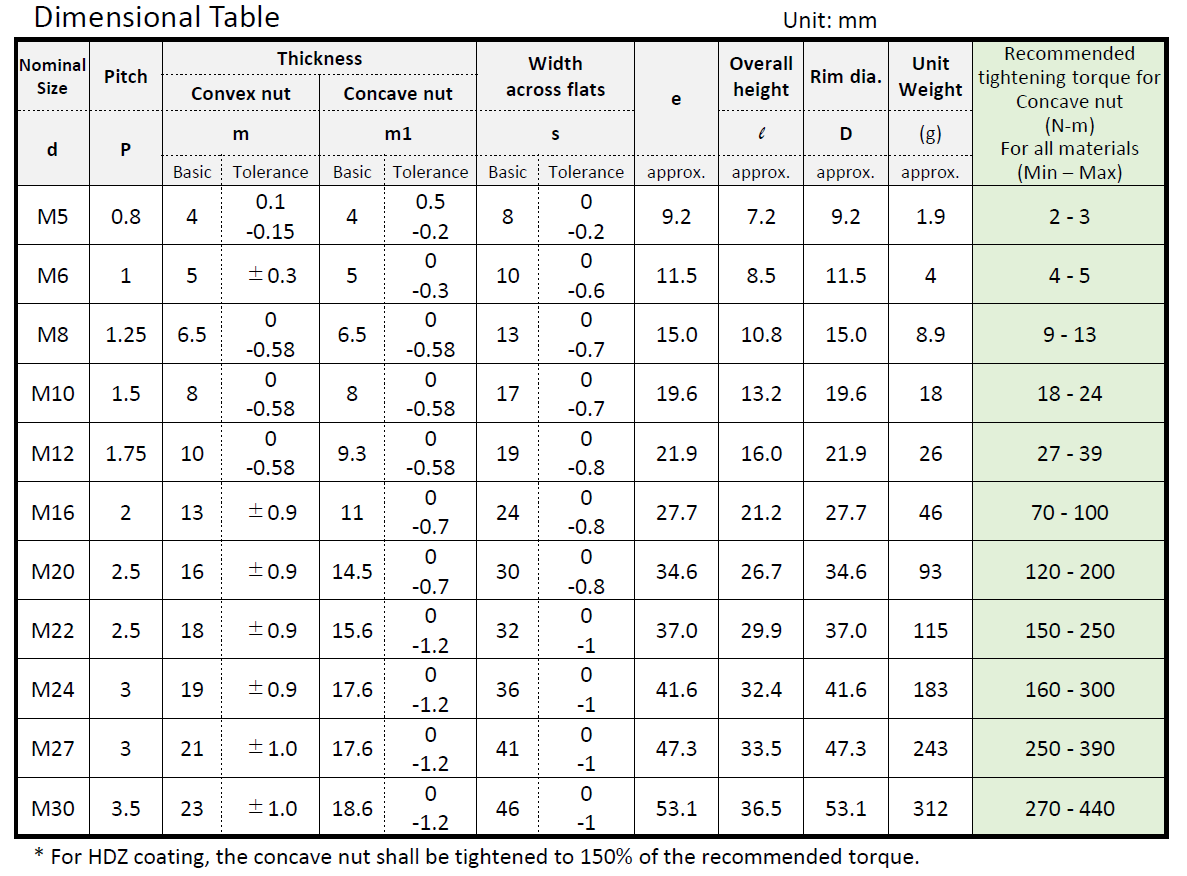

| Nominal Size | Pitch | Nominal Size | Pitch |

| d | P | d | P |

| M5 | 0.8 | M16 | 2 |

| M6 | 1 | M20 | 2.5 |

| M8 | 1.25 | M22 | 2.5 |

| M10 | 1.5 | M24 | 3 |

| M12 | 1.75 | M27 | 3 |

| M30 | 3.5 |

| Description | HARDLOCK Nut composed of two nuts, concave and convex nut is designed to withstand severe vibration and compression loading forces. HLN-R has a rim on the bottom surface of the Concave Nut for increased workability. Only metric course thread is available. |

| Standard | External dimensions: JIS B1181(2014) Annex JA (Width across flats only) Thread tolerances: 6H JIS B0209(2001)/ISO 965 |

| Material | Class 4 JIS SS400 equivalent (Law Carbon Steel) Class 8 JIS S45C (Medium Carbon Steel) – Heat treated Class 10 JIS SCM435 (Chromium Molybdenum Steel) – Heat treated A2-70 JIS SUS304 equivalent (Stainless Steel) * HLN-R Class8 and Class10 are only available for M8 or bigger. * HLN-R A2 is only available up to M16. |

| Surface Treatment | Class 4 with Trivalent Chromate or Hot-dip Galvanizing (HDZ 35) (for M8 or bigger) Class 8 with Manganese Phosphate coating or Zinc Trivalent Chromate Class 10 with Manganese Phosphate coating A2 in plain/uncoated *Other surface treatments are available on made-to-order basis. |

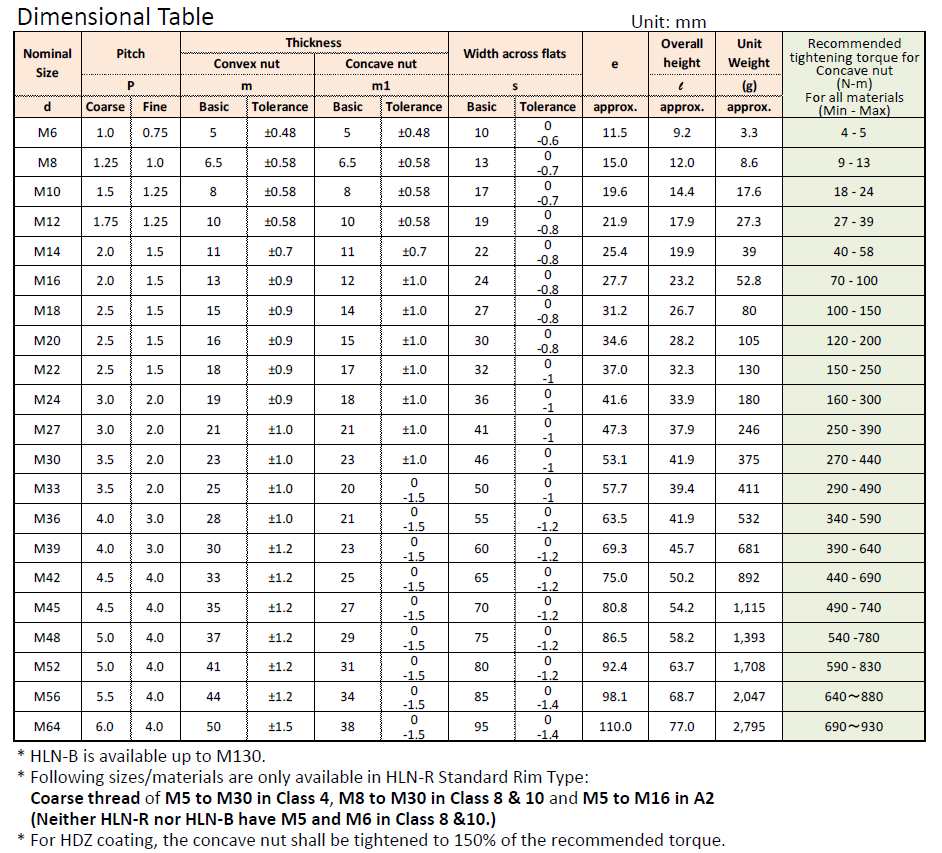

HARDLOCK NUT Basic Type (HLN-B)

| Nominal Size | Pitch | Nominal Size | Pitch | ||

| P | P | ||||

| d | Coarse | Fine | d | Coarse | Fine |

| M6 | 1.0 | 0.75 | M30 | 3.5 | 2.0 |

| M8 | 1.25 | 1.0 | M33 | 3.5 | 2.0 |

| M10 | 1.5 | 1.25 | M36 | 4.0 | 3.0 |

| M12 | 1.75 | 1.25 | M39 | 4.0 | 3.0 |

| M14 | 2.0 | 1.5 | M42 | 4.5 | 4.0 |

| M16 | 2.0 | 1.5 | M45 | 4.5 | 4.0 |

| M18 | 2.5 | 1.5 | M48 | 5.0 | 4.0 |

| M20 | 2.5 | 1.5 | M52 | 5.0 | 4.0 |

| M22 | 2.5 | 1.5 | M56 | 5.5 | 4.0 |

| M24 | 3.0 | 2.0 | M64 | 6.0 | 4.0 |

| M27 | 3.0 | 2.0 | |||

| Description | HLN-B complements HLN-R by providing fine thread, thin type, diameters of bigger than M30 for C4/C8/C10 & bigger than M16 for A2 and inch thread. |

| Standard | External dimensions: JIS B1181(2014) Annex JA (Width across flats only) Thread tolerances: JIS B0209(2001)/ISO 965 6H |

| Material (Standard stock) | Class 4 JIS SS400 equivalent (Law Carbon Steel) Class 8 JIS S45C (Medium Carbon Steel) – Heat treated Class 10 JIS SCM435 (Chromium Molybdenum Steel) – Heat treated A2-50 JIS SUS304 equivalent (Stainless Steel) |

| Surface Treatment (Standard stock) | Class 4 with Trivalent Chromate or Hot-dip Galvanizing (HDZ 35) Class 8 with Manganese Phosphate coating or Zinc Trivalent Chromate Class 10 with Manganese Phosphate coating A2 in plain/uncoated *Other surface treatments are available on made-to-order basis. |

Kouei is Distributor/Agent of Hard Lock Nut

Other items of Hard Lock Nut

Request the quotation for Hard Lock Nut