HISAKA WORKS.LTD.

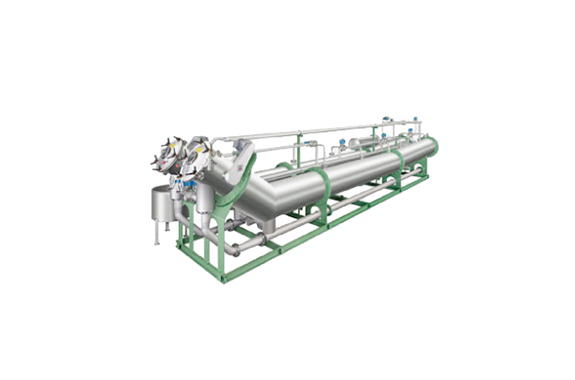

HISAKA Circular CUT-XF Jet Dyeing Machine

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: Circular CUT-XF

In combination with a new, highly functional system, it offers further improvements in productivity of the dyeing plant, lower costs and also eliminates human differences.

Improving productivity and reducing costs

- The new structure improves the effective internal volume (15% better than current models) and contributes to solve the wrinkling problem of high difficulty materials.

- With the newly developed high temperature discharge & rinsing system (HTRS) and low liquid washing system (LLR), contributing to the time reduction and running costs.

Reduction of accident rate and improvement of reproducibility

- Special tanks at the end of front and rear eliminate clogging at the rear and achieve stable running from low to high temperature by realizing uniformity of stagnation balance.

- In the rear special tank, machining defects due to conventional low nozzle pressure are eliminated.

- With the newly developed Automatic Setting System (EDIC’s), Powder Dye Dissolving System (HDE), and New Injection Control System, eliminating human differences.

Easy operation and space saving design

- Sophisticated and simple structure improves operability and reduces workloads and losses.

- Installation space for various high performance systems is also secured.

Specification

Model : CUT-XF (Jet dyeing machine series)

| Item & Model | Circular XF-Series | Circular XF-Series (Large Capacity) | |||||

|---|---|---|---|---|---|---|---|

| CUT-XF-1 | CUT-XF-2 | CUT-XF-4 | CUT-XF-1 L | CUT-XF-2L | CUT-XF-4L | ||

| Max.Temperature | X | 140 | 140 | ||||

| Max.W.Pressure | MPa (kg/cm2G) | 0.49 (5.0) | 0.49 (5.0) | ||||

| Liquor | lit | 700-1100 | 1400-2200 | 2800-4000 | 800-1300 | 1600-2600 | 3200-5200 |

| Capacity | kg | 60-170 | 120-340 | 240-680 | 70-200 | 140-400 | 280-800 |

| Power | kW/hr | 17-18 | 33-34 | 60-61 | 17-18 | 33-34 | 60-61 |

| Heating Rate 20-H30X ByO.8MPa (8kg/cm?) saturated steam | min | 20 | 20 | ||||

| Cooling Rate 130-*80eC By 20’C cooling water | min | 15 | 15 | ||||

| Fabric Speed | m/min | 50-500 | 50-500 | ||||

Related Products

-

HISAKA HF5 FLOATING 2-WAY BALL VALVE CERAMIC LINNING

-

HISAKA HF5 FLOATING, 2-WAY BALL VALVE PTFE COATING

-

HISAKA CUT-MR-M Series Circular Testing Jet Dyeing Machine

-

HISAKA Lift Type Cooling System Fully Automated Continuous Sterilizer

-

HISAKA Flash Type Evaporator

-

HISAKA HS5 Screw Ends, Full Bore, Ball Valve