HISAKA WORKS.LTD.

HISAKA FX Series Plate Heat Exchanger For Food

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: FX Series

Food dedicated plate to solve the problem of food production line.

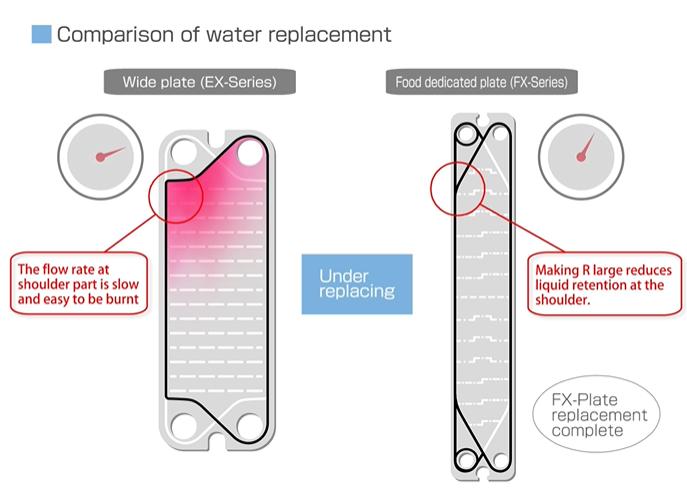

Smooth and product-friendly liquid flow through the plate provides uniform heating and quick liquid replacement characteristics.

The electrolytic polishing plate prevents from the scales and burnt, and can be cleaned with CIP.

Features

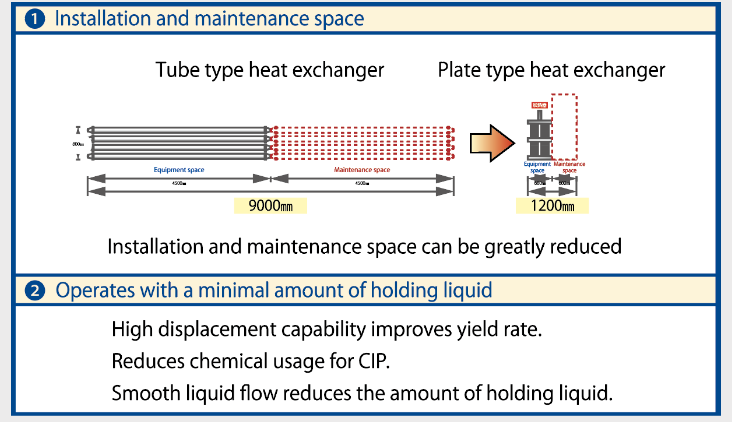

- Uniform and smooth liquid flow realizes uniform heating and cooling of products, reducing the amount of holding liquid.

- The electrolytic polishing plate reduces the deposition of the scale, allowing long continuous operation.

- Improved cleanability by greatly reducing the number of contact points between plates and preventing from the scales and burnt.

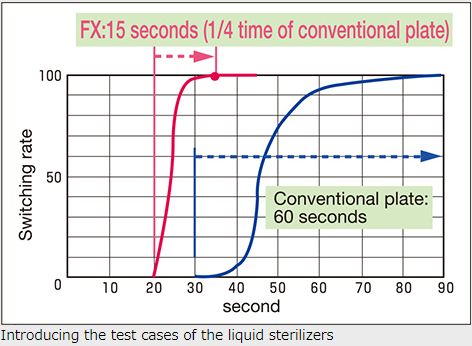

- By realizing the piston flow, the liquid replacement time is greatly shortened, and it contributes to the reductions of the operation time and products loss.

Liquid Displacement Test Data

Applications

| Beverages | Bottled water, water, tea, juice, coffee, soda (syrup), milk, cream, condensed milk, jelly, yogurt, mayonnaise, etc. |

|---|---|

| Brewings | Soy sauce, noodle soup, sake, cloudy sake, amazake, liqueur, wine, whisky, shochu, etc. |

Scope Of The Application

FX series lineup

| Model | Capacity | Max. Pressure | Max. Temp. | Nozzle Dia. | Frame Size (mm) |

|---|---|---|---|---|---|

| FX-01 | 0.05~1m³/h | 1.4MPaG | 150℃ | 15A | W160×H585 |

| FX-10 | 0.4~5m³/h | 1.2MPaG | 150℃ | 1.5S | W290×H1220 |

| FX-03 | 0.8~25m³/h | 1.5MPaG | 150℃ | 2S | W540×H1735 |

| FX-30 | 0.8~25m³/h | 1.5MPaG | 150℃ | 2S | W540×H1735 |

| FX-05 | 5~60m³/h | 1.5MPaG | 150℃ | 3S | W840×H2500 |

Note: Please be aware that the dimensions may be changed without notice.

Applicable Material

Plate / SUS316, Titanium

Gasket / EPDM, fluorine resin cushion gasket (TCG), silicon

Plates for solids

Features

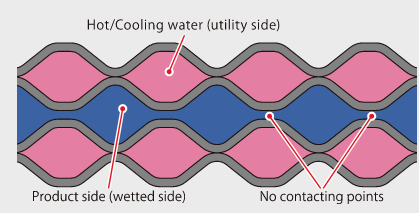

- The heat-transfer area where liquid flows on the product side has no contact points where the plates come into contact with each other, so pulp is less likely to get caught.

- Food-specific plate: Inherits the good liquid displacement and washability of the FX-03 type

Structural drawing (cross-sectional view)

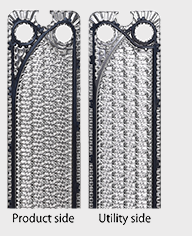

Plate shape

- The plate inherits the vertical structure and gentle shoulder shape of conventional products.

Features

- It reduces accumulation of solids at hit points (vegetable drinks, tomato juice, ketchup, etc.)

- It reduces the effects of shearing (cream, liquid egg, etc.)

Development test lab. – Continuous liquid sterilization

- Soft drinks, noodle soup, etc.

- Soft drinks such as tea and mineral water, seasonings such as noodle soup and soy sauce, and liquid eggs are relatively low in viscosity and are sterilized by plate type sterilizer.

The high temperature rapid sterilization (HTST) can sterilize products with minimal heat damage.

- Dressing, ramen noodles soup, etc.

- Tube type sterilizers are suitable for solid seasonings such as sesame, pulp-containing beverages, high viscosity liquids such as ramen soup and concentrated extract, and semi-liquid products such as grated yam and root of the seaweed.

If the pressure loss increases, the booster pump is used to achieve stable operation.

- Milk, dessert paste, etc.

- The plate type sterilizer had limitations in terms of product quality and continuous operability because the quality deterioration due to heat is remarkable, and the heat-denatured components often cause scale.

The spin injection is a direct steam heating system that instantaneously mixes steam with liquid uniformly, solving the problems of both quality improvement and long-term operation.