HISAKA WORKS.LTD.

HISAKA Lift Steamer Z Fully Automated Continuous Sterilization Cooling System

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: Lift steamer Z

It is ideal for mass production because uniform heating and cooling of sealed chilled foods can be performed continuously.

Features

1. Accurate and easy temperature control

The temperature of the heating chamber is precisely and stably controlled by PID control simply setting an arbitrary temperature from 60 up to 100℃ at the control panel.

2. Significant energy saving

The consumption of steam is about 50% compared with the hot water type, since there is no steam outflow from the equipment and the heat loss is very low.

3. Shorten warm-up time

Since there is no necessity of boiling water, compared with the conventional hot water type, warm-up time of the equipment is significantly reduced.

4. Improvement of the factory environment and reduction of equipment and plant maintenance costs

Since there is no steam outflow from the equipment, the temperature and humidity rise in the factory can be prevented even without exhaust fans or ducts, and total cost reduction is possible.

5. Improvement of the product quality and value

The texture, color and flavor of the product are good compared with the hot water sterilization, and also the surface gloss of the product remains very beautiful.

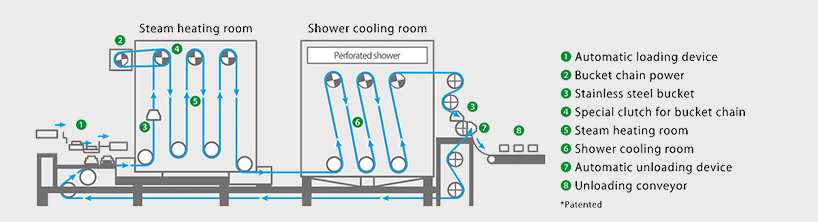

- 1. Products flowing from the conveyor on the filling machine side are stored in buckets by an automatic feeding device.

- 2. Sterilized in a steam-heated room and cooled in a shower-cooled room on the same bucket.

- 3. After being taken out by an automatic unloading device, it is sent to a next process.

Applications

| Molded container | Jelly, tofu, savory egg custard, egg tofu, etc. |

|---|---|

| Pouch | Curry for business use and individual consumption, side dishes, etc. |

| Spout pouch | Jelly beverages, etc. |

| Deep drawing | Crab sticks, meat products, etc. |

| Pillow | Custard cream, konjac, etc. |