HISAKA WORKS.LTD.

HISAKA SBD Vacuum Belt Dryer

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: SBD

The high-quality solution is realized by continuous drying of highly concentrated solutions under a vacuum.

The continuous vacuum drying system dries high viscosity liquid that is difficult to process by spray drying type at low temperatures, and producing the highly soluble dried products in a short time.

Drying System

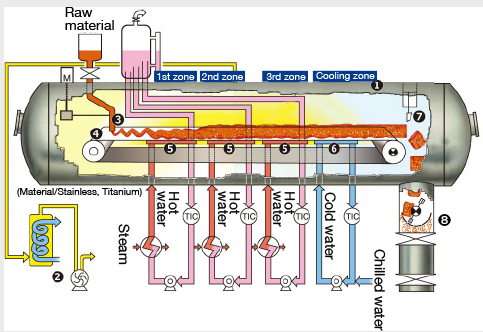

- In the vacuum tank [1] of the main body, while operating by the cold trap and the vacuum pump [2], the vacuum degree below 10Torr is kept.

- The raw materials in high concentration and high viscosity in the form of the liquid, slurry, and paste are uniformly dispersed in thin layer form on the belt [4] which is operated by the raw material supply facility and the uniform dispersion nozzle [3].

- There are three heating plates [5] and a cooling plate [6] on the underside of the belt, when the material on the belt passes through the heating zone, it dries at a low temp.

In this case, the thin membrane raw material evaporates violently the internal water forms a porous format with a large number of vents in the interior as well as swelling. - When being cooled down in the cooling zone the product temp. drops, it hardens, and arrives at the end of the belt.

- In the end, the granules are primarily pulverized with the pre-crusher [7], which is attached to the top of the vacuum tank, and the main crusher [8] pulverizes them again to produce the best soluble porous granules.

Features

1. High-quality dried products can be produced in a short time

- Low-temperature drying around 40℃ is ideal for heat-sensitive raw materials, excellent in solubility and restorability.

- The raw materials are hygienic and prevent oxidation because it is dried and pulverized in a vacuum tank.

- Less scattering loss of raw materials and products, resulting in dry products of the same amount and same quality as raw materials.

2. High efficiency and economical drying

- The selection of the drying rate according to the physical properties enables high concentration and high viscosity drying in the form of the liquid, slurry, and paste.

- Continuous drying is more efficient than batch type.

- Design considering heat efficiency and drying efficiency, minimizing incidental equipment such as exhaust and drainage to reduce costs.

Drying

- Continuous drying of liquid, slurry and pasty raw materials

- Since high viscosity liquids such as various soups, beef extracts, and oligosaccharides are continuously dried at low temperature under vacuum, a high quality dried powder without heating history can be obtained.