HISAKA WORKS.LTD.

HISAKA Tube Type Liquid Continuous Sterilizer

Product Made In Japan

Manufacturer: HISAKA WORK LIMITED

Model: Tube Type

Multi-product production with a wide range of lineup

Sterilizers corresponding to the multi-product production for water soluble liquid, high viscosity liquid, solids or fiber containing liquid, etc.

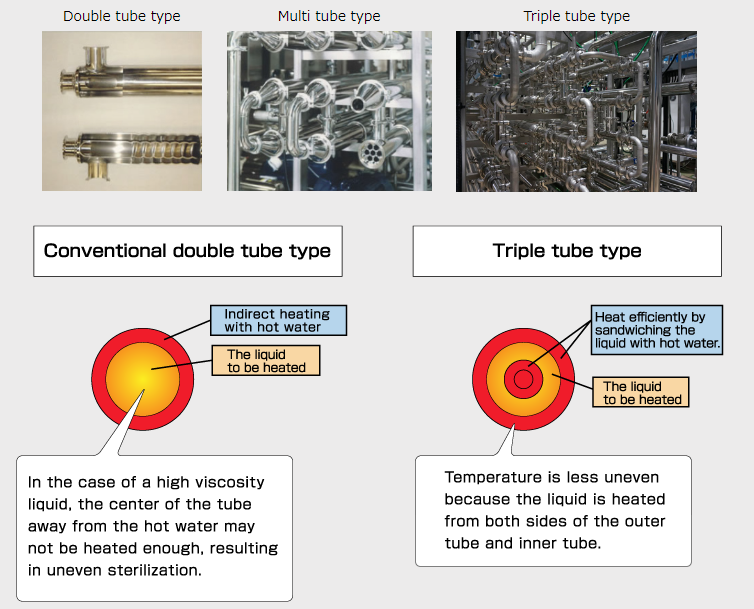

Depending on the conditions such as liquid properties and processing amount, they are supported by a rich lineup of single tube, multi tube, shell & tube, and triple tube.

Features

- Many types of liquid are applicable, and it can be applied to products from low to high viscosity (~10,000 mPa・S), containing solids and fibers.

- Excellent liquid replacement is best for a wide variety of products.

- Easy maintenance due to limited use of gaskets.

- The small wetted area of the gasket reduces the flavoring and residual fragrance.

- Uniform flow realizes excellent detergency, allowing for long-term operation even for products that are easy to burnt.

Applications

Seasonings Barbecue sauce, dressings, mayonnaise, sauces, ketchup, mash vinegar, amino acids, sesame sauce, miso sauce, noodle soup, pot soup Beverages Fruit juice, juice, soy milk, juice, tea, sports drink, coffee, amazake Milks Milk, coffee milk, cream, pudding, jelly Extracts Meat extract, seafood extract, vegetable extract, soup Others Health drink and health food

Development test lab. – Continuous liquid sterilization

- Soft drinks, noodle soup, etc.

- Soft drinks such as tea and mineral water, seasonings such as noodle soup and soy sauce, and liquid eggs are relatively low in viscosity and are sterilized by plate type sterilizer.

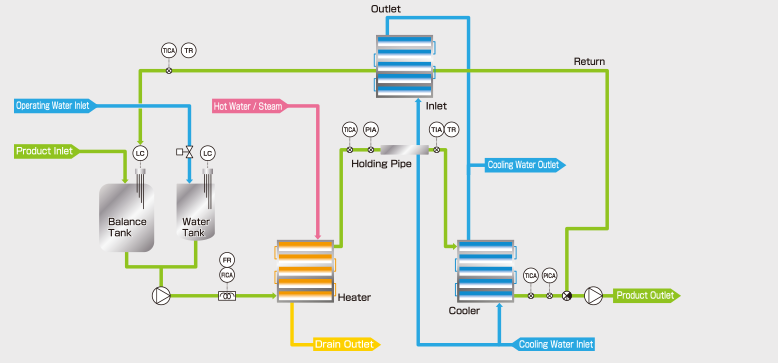

The high temperature rapid sterilization (HTST) can sterilize products with minimal heat damage.

- Dressing, ramen noodles soup, etc.

- Tube type sterilizers are suitable for solid seasonings such as sesame, pulp-containing beverages, high viscosity liquids such as ramen soup and concentrated extract, and semi-liquid products such as grated yam and root of the seaweed.

If the pressure loss increases, the booster pump is used to achieve stable operation.

- Milk, dessert paste, etc.

- The plate type sterilizer had limitations in terms of product quality and continuous operability because the quality deterioration due to heat is remarkable, and the heat-denatured components often cause scale.

The spin injection is a direct steam heating system that instantaneously mixes steam with liquid uniformly, solving the problems of both quality improvement and long-term operation.

Related Products

-

HISAKA Lift Type Cooling System Fully Automated Continuous Sterilizer

-

HISAKA LLC High Temperature and High Pressure Cheese Dyeing Machine

-

HISAKA HF5-TDT and TST 2-STAGE CONTROL BALL VALVE

-

HISAKA HF5(SJ) SEMI JACKET BALL VALVE

-

HISAKA GY Coil Rotation Type Global Evaporator

-

HISAKA HF5CA CARBON SEAT 2-WAY BALL VALVE