Hishiko

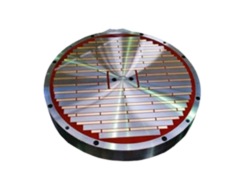

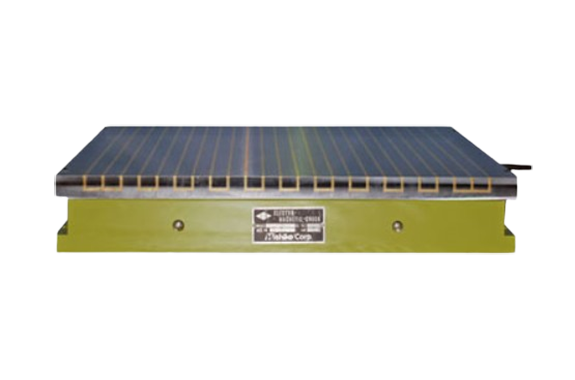

Hishiko KFA Series Electro Magnetic Chuck For Grinding

Manufacturer: Hishiko Co., Ltd.

Model: KFA Series

Applications

Most common electromagnetic chuck mainly used for grinding workpiece.

Features

To meet the demands of grinding work that requires higher precision, the KFA is designed to reduce distortion caused by grinding heat and the heat generated by the coil installed in the chuck.

Air Float Electromagnetic Chuck

The face plate for air float type chuck has small holes. These holes blow out air, causing the workpiece to float. As a result, you can smoothly move even a large workpiece and easily place or remove it without any scratches on the workpiece or the face plate.

Water-cooled Electromagnetic Chuck

Cooling water runs through inside of the chuck and draws heat from the coils. It minimizes distortion of the chuck by heat and improves finishing precision.

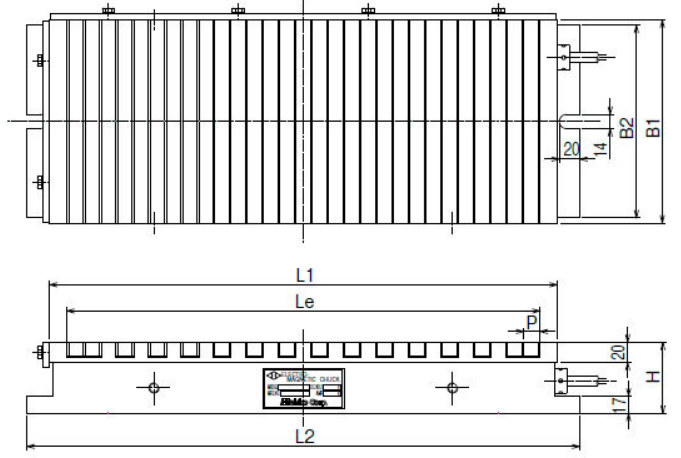

Specifications (mm)

With small-size

| Stock No | Model | Face Plate | Pole Pitch | Height | Bottom Plate | |||

| B1 | L1 | Le | P | H | B2 | L2 | ||

| S900101 | KFA100×250 | 100 | 250 | 212 | 14(12+2) | 70 | 98 | 294 |

| S900102 | KFA125×250 | 125 | 121 | |||||

| S900103 | KFA150×300 | 150 | 300 | 268 | 144 | 344 | ||

| S900104 | KFA150×350 | 350 | 296 | 394 | ||||

| S900105 | KFA150×450 | 450 | 408 | 494 | ||||

| S900106 | KFA200×500 | 200 | 500 | 466 | 16(14+2) | 190 | 544 | |

| S900107 | KFA200×600 | 600 | 562 | 644 | ||||

| Stock No | Model | Lead Wire Length(m) | Current(A)(DC100V) | Recommended Controller | Weight(kg) | ||

| Manual | Auto (with Rectifier) | ||||||

| Rectifier | Controller | ||||||

| S900101 | KFA100×250 | 1 | 0.17 | KS80X3 or KS100X3 | KNS0-A or KNS0-OS | HCC105AES1 | 12 |

| S900102 | KFA125×250 | 2 | 0.20 | 14 | |||

| S900103 | KFA150×300 | 0.25 | 20 | ||||

| S900104 | KFA150×350 | 0.29 | 24 | ||||

| S900105 | KFA150×450 | 0.36 | 30 | ||||

| S900106 | KFA200×500 | 0.43 | 45 | ||||

| S900107 | KFA200×600 | 3 | 0.57 | 55 | |||

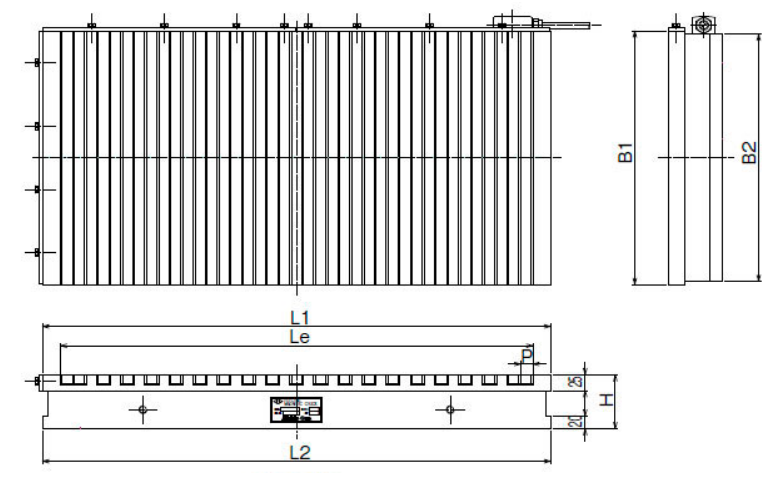

With large-size

| Stock No | Model | Face Plate | Pole Pitch | Height | Bottom Plate | |||

| B1 | L1 | Le | P | H | B2 | L2 | ||

| S900108 | KFA250× 500 | 250 | 500 | 440 | 19 (16+3) | 80 | 240 | 500 |

| S900109 | KFA250× 600 | 600 | 554 | 600 | ||||

| S900110 | KFA300× 500 | 300 | 500 | 440 | 290 | 500 | ||

| S900111 | KFA300× 600 | 600 | 554 | 600 | ||||

| S900112 | KFA300× 900 | 900 | 820 | 85 | 900 | |||

| S900114 | KFA400× 500 | 400 | 500 | 440 | 390 | 500 | ||

| S900115 | KFA400× 600 | 600 | 554 | 600 | ||||

| S900116 | KFA400× 800 | 800 | 744 | 800 | ||||

| S900117 | KFA400×1000 | 1000 | 934 | 1000 | ||||

| S900119 | KFA500×500 | 500 | 500 | 440 | 490 | 500 | ||

| S900120 | KFA500×600 | 600 | 554 | 600 | ||||

| S900121 | KFA500×1000 | 1000 | 934 | 1000 | ||||

| Stock No | Model | Clamps(pieces) | Lead Wire Length(m) | Current(DC100V) | Recommended Controller | Weight(kg) | ||

| Manual | Auto (with Rectifier) | |||||||

| Rectifier | Controller | |||||||

| S900108 | KFA250× 500 | 2 | 2 | 0.47 | KS80X3 or KS100X3 | KNS0-A or KNS0-OS (With Rectifier) | HSC093E or HCC105AES1 | 65 |

| S900109 | KFA250× 600 | 3 | 0.72 | 78 | ||||

| S900110 | KFA300× 500 | 4 | 2 | 0.61 | 78 | |||

| S900111 | KFA300× 600 | 3 | 0.86 | 93 | ||||

| S900112 | KFA300× 900 | 4 | 1.66 | KNS0-A | 140 | |||

| S900114 | KFA400× 500 | 3 | 0.87 | KNS0-A or KNS0-OS (With Rectifier) | 100 | |||

| S900115 | KFA400× 600 | 1.15 | KNS0-A | 132 | ||||

| S900116 | KFA400× 800 | 1.30 | 170 | |||||

| S900117 | KFA400×1000 | 4 | 2.08 | 220 | ||||

| S900119 | KFA500×500 | 3 | 1.06 | 138 | ||||

| S900120 | KFA500×600 | 1.39 | 165 | |||||

| S900121 | KFA500×1000 | 4 | 2.90 | HCC105AES1 | 275 | |||