IHARA SCIENCE CORPORATION

IHARA NE Bite Type Tube Fittings

Product Made In Japan

Manufacturer: IHARA SCIENCE CORPORATION

Model: NE Bite Type

Features

- Bite-type fittings do not require threading, welding, flaring or brazing to perform piping and substantial man-hour savings can be realized.

- Without requiring threading nor welding, thin wall tubes can be used for piping (tube wall thickness is required to be more than 10% of the tube outside diameter due to the type fitting mechanism and rigidity of the tube, however, the minimum thickness must be more than 1 mm). Thin wall tubes facilitate bending and enable reducing the number of fittings which will contribute to decrease the weight of the equipment as well as permit compactness.

- Even after repeated disassembly and remake, the connection made is both integral and reliable.

- Sealing is achieved by metal contact without involving sealing material such as an O-ring, application over a wide temperature range is feasible.

- Fitting material can be selected from carbon steel, stainless steel, brass, and other metals to adapt to the conditions of application such as the fluid to be handled and the external environment.

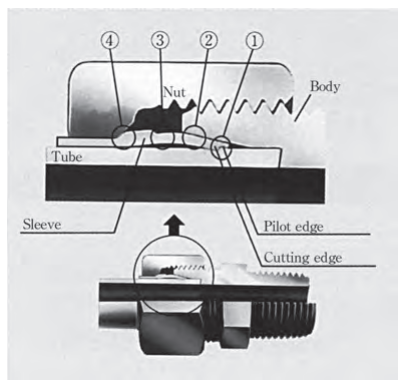

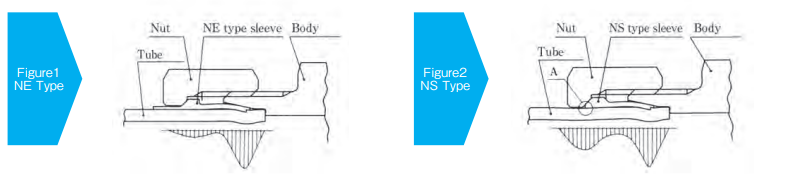

Fitting Mechanism

The bite type fitting consists of 3 components, namely, the body, the nut, and the sleeve, and by properly assembling the components and tightening in accordance with the specified procedure, the sleeve will bite into the tube as illustrated in the figure.

- The cutting edge of the sleeve will bite into the tube to firmly hold the tube and at the same time performs sealing between the sleeve and the tube.

- The outer periphery of the sleeve is tightly pressed along the tapered bore surface of the body and performs sealing between the sleeve and the body.

- The bowing action of the sleeve works as a powerful spring and maintains sealing function over a long period of time as well as prevent the nut from becoming loose by vibration.

- The rear portion of the sleeve is compressed against the outer periphery of the tube and holds the tube as well as relieve stress concentration from vibration to the part where the sleeve bites into the tube

The mechanism of the bite type fitting as explained above enables the fitting to completely seal high pressure fluid even where the piping undergo impact, vibration, etc.

TUBE SELECTION

Tubes that are mainly applicable for use with the fittings are listed below, and steel tubing of (1), (2) and (6) are particularly adaptable and recommended for piping application with these fittings.

- JIS B 2351 Pipes for oil hydraulic service 25 MPa (250 kgf/cm2), STPS standard pipes for bite type tube fitting:

- Japan Oil Hydraulic Industrial Society Standard JOHS-102 Precision carbon steel tube for oil hydraulic piping: OST various types

- Standard JIS G 3454 Carbon steel pipes for general service: STPG 370

- JIS G 3455 Carbon steel pipes for high pressure service: STS 370

- JIS G 3456 Carbon steel pipes for high temperature service: STPT 370

- Electric-resistance-welded carbon steel tube for E tube oil hydraulic piping (in-house standard)

- SUS 304TP and SUS 316TP specified in stainless steel piping for JIS 3459 piping

⚠ CAUTION: In case of using (3), (4), (5) and (7) above, select ones which are cold finished seamless pipes with surface hardness less than HRB 80.

Standard Specification

| Fitting sizes IApplicable nominal tube) | For mm tube | 4-8 | 10-15 | 16-25 | 28-30 | 35-38 | 40-50 |

|---|---|---|---|---|---|---|---|

| For schedule pipe | 1/8 • 1/4 | 3/8 • 1/2 | 3/4 | 1 | 1-1/4-1-1/2 | ||

| Rated pressure | MPa | 50 | 40 | 31 | 28 | 25 | 21 |

| Temperature range | °C | – 20 —F250°C | |||||

WARNING:Use in excess application is forbidden

Material

(1)Body and Nut

JIS G 4051 Carbon steel material for machinery structure 25C~S48C or material equivalent.

(2)Sleeve

Carbon steel with surface hardened.

(3)Stainless steel(SUS304 and SUS316)is also available

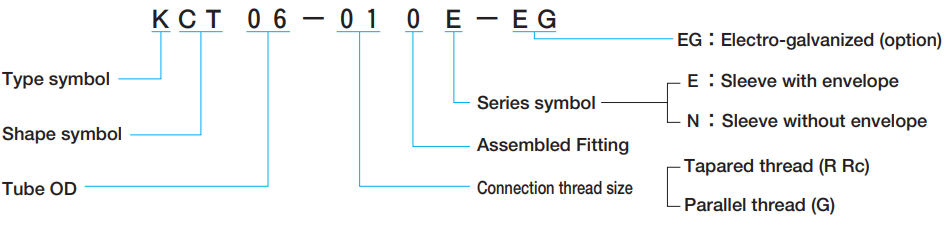

PART NUMBERS (NOMENCLATURE) AND STANDARD SIZES

| mm tube | OD size | 4 | 6 | 8 | 10………30………50 | ||||

|---|---|---|---|---|---|---|---|---|---|

| Nominal size | 04 | 06 | 08 | 10………30………50 | |||||

| Schedule Pipe | Nominal diameter (B) | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 11/4 | 11/2 |

| OD size | 10.5 | 13.8 | 17.3 | 21.7 | 27.2 | 34.0 | 42.7 | 48.6 | |

| Nominal size | 11 | 13 | 17 | 21 | 27 | 34 | 43 | 48 | |

| Connection ttread | 1/8 | 1/4 | 3/8 | 1/2 | 3/4 | 1 | 1-1/4 |

|---|---|---|---|---|---|---|---|

| Nominal size | 01 | 02 | 03 | 04 | 06 | 08 | 10 |

WARNING: The intermixing use of bite type fittings parts (body, nut, sleeve) with other companyʼs is forbidden.

Because fittings donʼt function properly and may cause the serious accident.