IKURA SEIKI, Japan

IKURATOOLS IS-756LMⅡ Angle Master II

Made in: Japan

Manufacturer: IKURA SEIKI

Model: IS-756LMⅡ

Feature

High Power: With a maximum pressure of 28 tons, stainless steel materials can be easily processed.

A significant reduction in operating noise has been achieved through soundproofing of each part: Thanks to noise reduction treatments in various parts, a significant reduction in operational noise has been achieved.

High Precision Processing: By adopting a newly designed blade, it’s possible to process with high precision and minimal burring.

Easy Operation: Operation is as simple as pressing a foot switch, and attachments can be exchanged with just one touch.

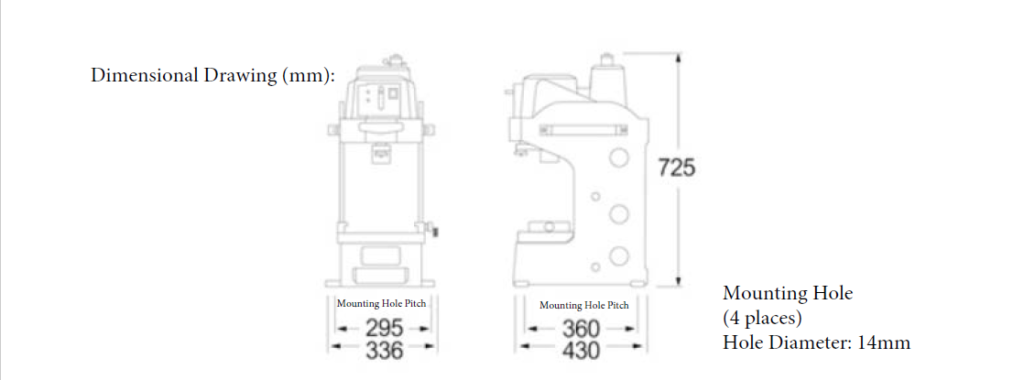

Specifications

| Maximum Processing Pressure: | 275kN (28 tons) |

| Motor: | AC 100V, 50/60Hz |

| Power Consumption: | 1400W |

| Main Spindle Stroke Length: | 0-45mm, continuously adjustable |

| Attachment: | One-touch exchange system |

| Weight: | 113kg. |

Standard Accessories

Hex wrenches #3・6・8, open-end wrenches 10・17, foot switch (cord length: 2.5m)

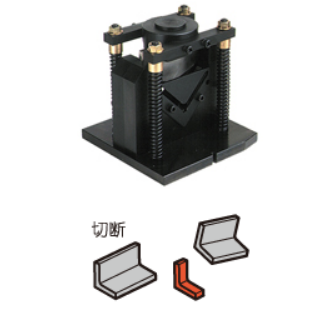

Cutter Attachment C756-Ⅱ

Specifications

| Maximum Processing Capacity: | Angle material SS400: L75×75×t6 Angle material SUS304: L75×75×t6 |

| External Dimensions: | W223×L220×H214mm |

| Weight: | 22kg |

Standard Accessories

Safety cover (for both ends of the blade)

Notcher Attachment V756-II

Specifications

| Maximum Processing Capacity: | Angle material SS400: L75×75×t6 Angle material SUS304: L75×75×t6 |

| External Dimensions: | W223×L220×H217mm |

| Weight: | 23kg |

Standard Accessories

Safety guard, push stopper.

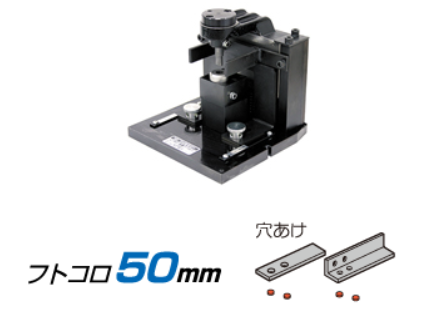

Puncher Attachment P756-II

Specifications

| Maximum Processing Capacity: ※For material width within 100mm |

Angle material SS400: Φ20 t10 Angle material SUS304: Φ20 t6 |

| External Dimensions: | W223×L220×H216mm |

| Weight: | 19 kg |

Standard Accessories

Material stopper, push guide, round hole punch & die (H11B)

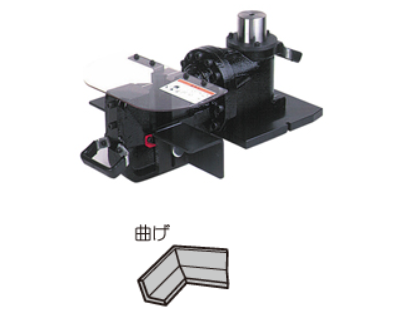

Bender Attachment B756-Ⅱ

Specifications

| Maximum Processing Capacity: | Angle material SS400: L75×75×t6 Angle material SUS304: L75×75×t6 |

| External Dimensions: | W320×L505×H255mm |

| Weight: | 40kg |

Standard Accessories

Safety guard, material receiving plate.