Ishida Valve Mfg Co.,Ltd

Ishida About Twin Pack Valves

Manufacturer: Ishida Valve Mfg Co.,Ltd

About the new stuffing box type val

Problems with conventional stuffing box valves

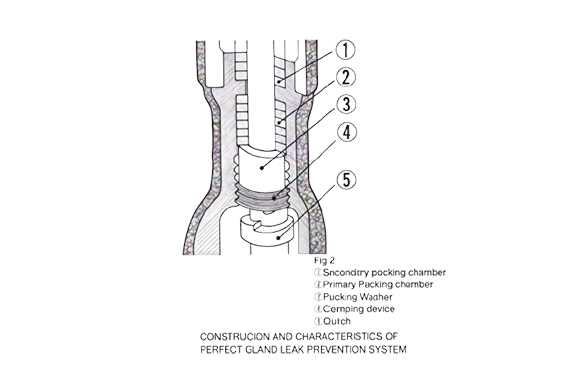

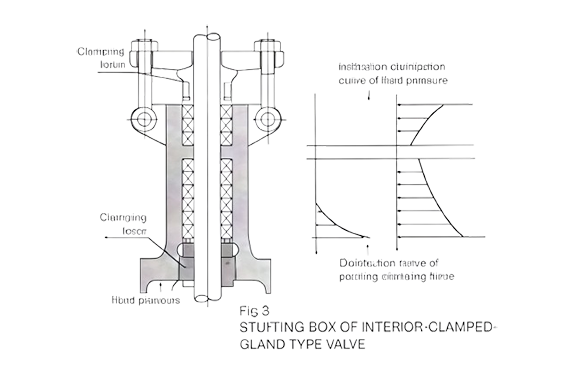

Conventional stuffing boxes absorb tightening forces unevenly, leading to rapid leakage. As internal pressure gradually penetrates the insufficiently tightened lower layer, the packing only seals after a few turns of the upper layer. Consequently, when sealants displace, leakage occurs, and the internal fluid fills the packing chamber. While tightening the gland packing temporarily seals it, the leakage resumes shortly after. Therefore, this cycle can lead to continuous performance issues unless properly addressed.

Conventional stuffing boxes absorb tightening forces unevenly, leading to rapid leakage. As internal pressure gradually penetrates the insufficiently tightened lower layer, the packing only seals after a few turns of the upper layer. Consequently, when sealants displace, leakage occurs, and the internal fluid fills the packing chamber. While tightening the gland packing temporarily seals it, the leakage resumes shortly after. Therefore, this cycle can lead to continuous performance issues unless properly addressed.“Twin Pack Valve” is a new stuffing box type valve proposed by Ishida Valve Industry.

Operation of Twin Pack Valves

Tightening Primary Packing

Always tighten the primary packing before fluid runs through the lines following the construction pressure test. This ensures a secure seal and prevents any leakage during operation. At the first sign of a leak during plant operations, immediately tighten the packing to prevent more significant issues down the line. Additionally, take advantage of the annual plant maintenance shutdown to tighten the packing, ensuring the valves remain in optimal condition and reducing the likelihood of failures during regular operation. By addressing these maintenance steps proactively, you can minimize downtime and ensure the system operates smoothly.

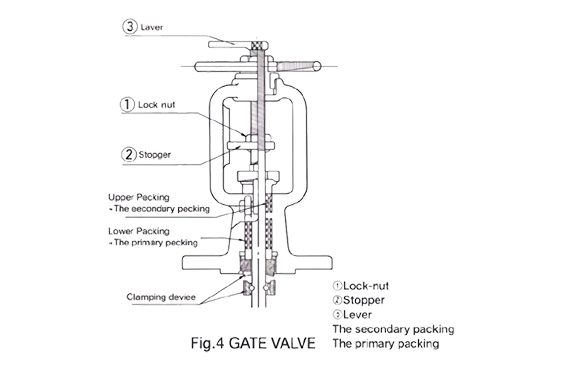

Pocedure for Applying Pressure to Primary PackingFor Gate Valves:

1. Open the Valve Fully: Turn the valve counterclockwise to the full open position.

2. Stop Turning: Once the wheel reaches its limit, stop turning.

3. Release the Lock Nut: Free the stopper by releasing the lock nut.

4. Clamp the Packing: Turn the step top lever clockwise by 30 to 45 degrees to clamp the packing.

5. Restore the Original Position: Tighten the lock nut and place the stopper back into its original position to maintain the valve’s initial state.

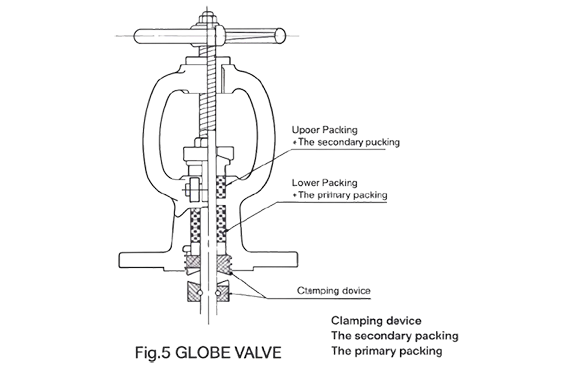

For Globe Valves and Forged Valves (1 1/2″ and Smaller):

1. Open the Valve Fully: Turn the valve counterclockwise until it’s fully open.

2. Stop Turning: Once the wheel stops turning, stop.

3. Clamp the Packing: Continue turning counterclockwise by 30 to 45 degrees to clamp the packing.

You can use Twin Pack valves on special fluids and special applications.

1. For heating media Downtherm A, Therm S, S-K Oil, Marlotherm, Essotherm, HTS, Hygrotherm, Fused Lead, Fused Sodium, Fused Potassium, etc

2. For high pressure, high temperature steam Downtherm A, Therm S, S-K Oil, Marlotherm, Essotherm, HTS, Hygrotherm, Fused Lead, Fused Sodium, Fused Potassium, etc

3. For hazardous gas and liquids such as hydrogen chloride (refer to the Yellow Twin Pack), hydrogen sulfide, phosgene, carbon monoxide, etc.

4. For prevention of pollution by preventing leaks of sulfurous acid gas, acetic acid, carbon dioxide.

5. For use for vacuum to a maximum 10-2mm Hg.

6. For low molecular weight gases Hydrogen, Oxygen, Freon, Gas, LPG etc.

7. For nuclear power plant.

Specifications

1. Nominal pressure class 150#, 300#, 600#, 900#, 1500#, 10K, 20K, 40K, 63K

2. Nominal bore size 1/2″~36″

3. Available as gate valves or globe valves

Materials

1. Body material for Twin Pack valves is in accordance with API 600. Common materials are carbon steel, alloy steel, and stainless steel.We can supply other materials, like monel, as required by the customer. Standard trim materials are 13 Cr and 18-8 stainless steel. Monel and other materials are available.

2. We use materials for trim, such as 13Cr and 18-8 stainless steels, in conformity with API STD 600. We can also use special materials, such as Monel metal, when requested by the customer.