ISHIKAWA

ISHIKAWA Design Panel/Perfo Art Punching Metal

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

Model: Design Panel/Perfo Art

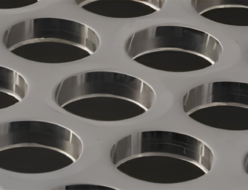

Design Punching Metal/PerfoArt for both Aesthetic and Functional Use in Architectural Interiors and Exteriors

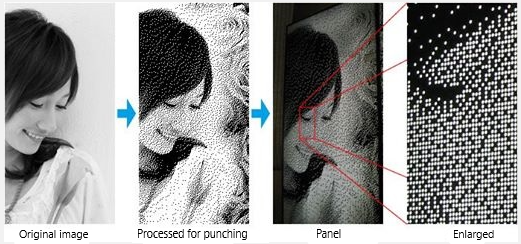

PerfoArt is created using Ishikawa Metal Mesh’s developed software for punching metal design, “Punch Editor”. Design punching metal that combines aesthetic appeal and functionality, that’s Design Punching Metal/PerfoArt. Punching metal that doesn’t produce a whistling sound, that’s Design Punching Metal/PerfoArt.

High-definition designs are expressed through Punch Editor. Random designs and gradient designs have resolved the whistling phenomenon.

The standard material used is aluminum. Other materials can be produced based on hole diameter, so please contact us for more information.

We respond to requests for both mass production and small-lot, multi-variety orders.

Perforated Design Variations

1) Art Design

At Ishikawa Wire Mesh, we use our own techniques to create the perforated metal design you want, as long as you provide us with an original drawing, such as a rough sketch or photograph, whether in color or monochrome. Even if you do not have one, we can suggest a design that matches your image from our design collection.

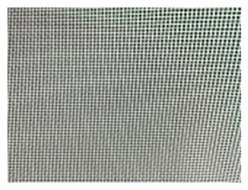

2) Random design

: 8φ and 4.5φ holes are drilled randomly according to the opening ratio.

The opening ratio can be adjusted up to 40% according to customer’s request.

The holes are paired to reduce whistling noise.

3) Gradient Design The

gradient design is effective when you want to control the line of sight or the amount of light in a certain direction.

The opening rate is gradually changed from the edge of the panel to randomly perforated holes.

The opening rate can be set in the range of 0% to 40% according to the desired pattern.

4) Checkered design

Checkered design is a highly decorative design with continuous panels. Various patterns beautifully decorate the wall.

By combining 8φ and 4.5φ hole diameters, a lattice pattern is formed, and the variations are endless.

Perforated Fall Variations

In addition to the conventional A0C-Type, we can accommodate a variety of hole diameters and sizes.

We can also accommodate holes other than round holes.

1) A-Type 10φ+4.5φ

2) B-Type 4.5φ

3) C-Type 8φ+4.5φ

4) Original pattern We will manufacture using a variety of multiple molds.

Production Procedure

- We will discuss installation and construction methods.

- Original design or photograph

Ishikawa Wire Netting original design - Reading with an image scanner

- Dot design is created using Ishikawa Wire Netting’s original software “Punch Editor”.

Based on this design, we will consider and revise it. - The data from the punch editor is converted to DXF and sent to the press or laser processing machine.

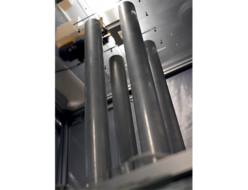

- Punching and laser processing:

Holes are made using a punching machine or a laser processing machine. - Straightening roll processing

: Distortions caused by punching and laser processing are corrected to create a flat plate. - Processing using bending machines, roll processing machines, and laser processing machines.

Cutting, bending, R bending, hemming bending, seam bending, etc. are performed. - Surface treatment

Anodizing, baking paint, etc.

The plate materials used are different for anodizing and baking paint.

Please specify the surface treatment method in advance.

Anodizing is a process that applies a protective film to the metal surface.

Unlike painting, anodizing cannot hide scratches on the metal surface, so the plate is processed with a film applied in advance. - Inspection, Packaging, Shipping

The product is packed in a protective sheet to prevent scratches on the surface before shipping.

PITR-ART

Silicone rubber, new techniques using plastics, punching metal for interior and exterior use, Pitoart

Pito Art is an original technique developed by Ishikawa Wire Netting that combines punched metal with silicone rubber or plastic.

Pito Art embeds colored silicone rubber or plastic into punched metal, faithfully reproducing the colors of the original painting. You can experience the magnificent beauty of a mosaic mural. Furthermore, when installed near a window, it can create the glow of stained glass, and when backlit, it can create the effect of a neon sign. Pito Art is an evolution of punched metal.

Silicone rubber and plastic can be made in any color.

Silicone rubber and plastic can be processed into various shapes.

We can also provide silicone rubber and plastic only.

Currently, we only have 8mm diameter silicone rubber in stock.

Pitotip (silicone rubber, plastic) can be made in any size you want.

Production Procedure

- We will discuss installation and construction methods.

- Original design or photograph

Ishikawa Wire Netting original design - Image Scanner Reading

- Using Ishikawa Wire Netting’s original software “Punch Editor”, we create colored dot designs.

We then review and revise the designs based on these designs. - The data from the punch editor is converted to DXF and sent to the press or laser processing machine.

- Punching and laser processing:

Holes are made using a punching machine or a laser processing machine. - Straightening roll processing

: Distortions caused by punching and laser processing are corrected to create a flat plate. - Processing using bending machines, roll processing machines, and laser processing machines.

Cutting, bending, R bending, hemming bending, seam bending, etc. are performed. - Surface treatment

Anodizing, baking paint, etc.

The plate materials used are different for anodizing and baking paint.

Please specify the surface treatment method in advance.

Anodizing is a process that applies a protective film to the metal surface.

Unlike painting, anodizing cannot hide scratches on the metal surface, so the plate is processed with a film applied in advance. - Embedding colored silicone rubber into perforated panels

You can also embed it yourself.

We also sell only Pitotip (silicone rubber). - Inspection, Packaging, Shipping

The product is packed in a protective sheet to prevent scratches on the surface before shipping.

[Patent]

No. 2789159 Punching device mold

No. 2841031 Method and device for punching holes in panels for pattern formation

No. 2673249 Punching decorative plate

[Utility Model]

No. 2577523 Decorative Plate

No. 3012839 Decorative Plate

[Design]

No. 1429570 Chair

No. 1436055 Wall Hanging

Major facilities and equipment owned:

Hand looms for wire mesh, automatic cutters for wire mesh, slitters for wire mesh, rolling machines for wire mesh, roll processing machines for wire mesh, power presses, various welding machines, levellers, benders, and other machine tools