ISHIKAWA

ISHIKAWA IK Screen Filter

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

ISHIKAWA IK Screen Filter Exclusively For Resin Extruders Wire Mesh

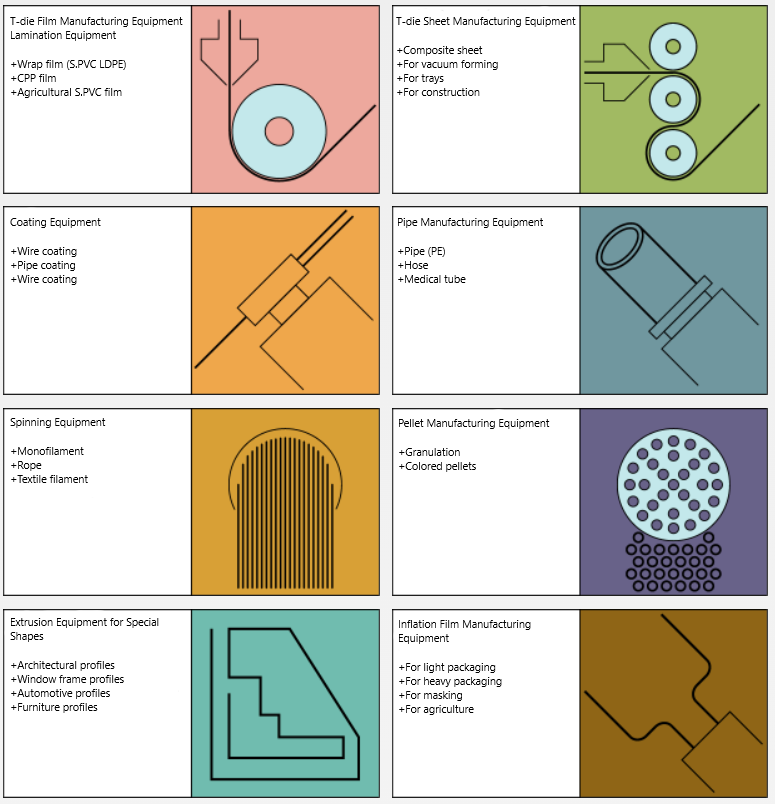

Polyethylene and polystyrene, synthetic resins, have become as important as metals in modern industry. Their usage fields are also expanding. Accordingly, manufacturers worldwide are developing extruders suited to various synthetic resin processed products.

However, in order to produce high-precision, high-quality resin with any extruder, it is necessary to remove impurities such as foreign matter, carbonized matter, gel-like matter, unmelted resin, etc. from the molten resin that cause contamination. For this purpose, a screen pack supported by a breaker plate is indispensable.

Ishikawa Wire Mesh has been manufacturing and selling IK Screen®, a filter exclusively for resin extruders, since the 1960s, using the technology it has cultivated in wire mesh manufacturing. It can accommodate a variety of extruders and extruder melt screen changers. We have accumulated experience and technology in manufacturing screens for extruders since the 1960s, and have a system in place that allows us to flexibly respond to new types of screen packs.

At Ishikawa Wire Netting, we have achieved cost reductions while maintaining quality through streamlining our manufacturing processes, in-house mold maintenance, and global material procurement, and we are strengthening our prompt delivery system.

Ishikawa Wire Netting provides a recycling service to collect used IK Screens® and reuse them as new resources. This not only reduces the burden on the environment, but also helps reduce waste disposal.

Compatible with a variety of resin extruders

Resin extruders are becoming more popular along with processed resin products. Ishikawa Wire Netting has a track record of manufacturing screen packs using the following resin extruder models. We are also actively challenging ourselves to manufacture screen packs compatible with new types of resin extruders, such as single-layer mesh (mono type), multi-layer mesh type (spot type), and frame reinforcement type (frame type). Please feel free to contact us.

Main specifications of IK Screen® (filter for resin extruders)

The opening size of the wire mesh used for IK Screen® can be made to order, from 0.04mm to 16mm. Please refer to the woven wire mesh product list for the mesh types. The product list explains the features of the representative products.

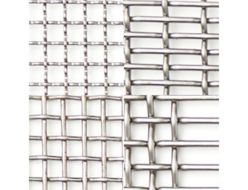

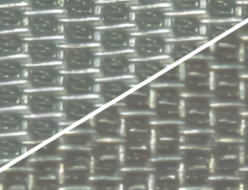

Types of woven wire mesh

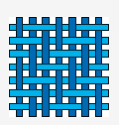

Plain weave:

A weaving method in which the vertical and horizontal lines intersect one another at regular intervals. This is commonly used as a standard wire mesh.

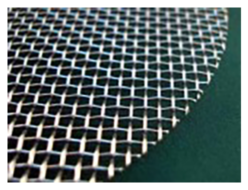

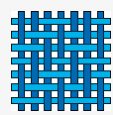

■ Twill weave:

This weaving method has vertical and horizontal lines spaced at regular intervals and crossing over each other two by two. Since two lines cross over each other, the angle of bending is large and it is possible to use relatively thick lines.

■ Herringbone twill:

We balance the twill weave by changing the weave at regular intervals to maintain the evenness of the folds.

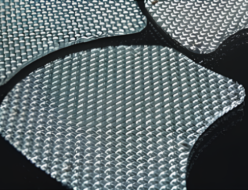

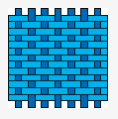

■ Flat tatami:

Weave: A weaving method spaces the vertical lines apart while closely spacing the horizontal lines, resembling the surface of a tatami mat. Generally, we use thick vertical lines, resulting in high strength. (In the diagram on the left, the vertical and horizontal lines have the same diameter, so no gaps are visible in the horizontal lines, but in actual flat tatami weave there are gaps.)

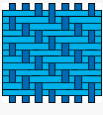

■

Twill This is a twill weave of plain tatami weave. The horizontal wires are in close contact with both sides of the wire mesh, ensuring twice the strength of plain tatami weave. (In the left image, the vertical and horizontal wire diameters are the same, so no gaps are visible in the horizontal lines, but in actual twill tatami weave there are gaps.)

Product Form

IK Screen® shapes include round, square, donut, oval, etc., and can be manufactured in diameters from 10mm to 1000mm in 0.5mm increments. We

offer approximately 400 different sizes ranging from 10mm to 400mm. Please contact us for stock availability.

Opening

We can manufacture IK Screen® with openings ranging from 0.04mm to 16mm. There are various combinations of openings, materials, and weaves. Please refer to the woven wire mesh product list for types. We

can also manufacture screens that combine pressure resistance and removal capabilities by layering multiple openings and wire diameters according to the application.

Available materials

Below is a list of materials that can be manufactured.

For corrosive resins such as fluororesin, Hastelloy and Monel are highly rated. Depending on the conditions of use, certain materials may show good results of 5 or more points. Please let our sales department know your usage conditions and environment and we will recommend the most suitable material for you.

Stainless steel

SUS304, SUS304L, SUS310S, SUS316, SUS316L, SUS317L

SUS321, SUS347, SUS430, SUS444

Iron

Iron, galvanized iron, FCHW2, Kanthal D

Copper

Copper, oxygen-free copper, brass, bronze, phosphor bronze

Nickel

Nickel 200, Nickel 201, NCHW1, Monel 400, Inconel 600, Inconel 601

Hastelloy C22, Hastelloy C270

Non-ferrous metals

Titanium, aluminum, molybdenum, tungsten

Used screen collection

We will collect your used IK Sc