ISHIKAWA

ISHIKAWA Plain Weave and Reverse Plain Weave High-Flow Woven Wire Mesh

Product Made In Japan

Manufacturer: ISHIKAWA WIRE NETTING Co.,Ltd.

Model: Plain Weave and Reverse Plain Weave

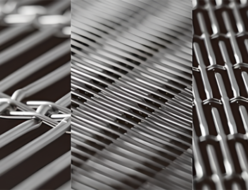

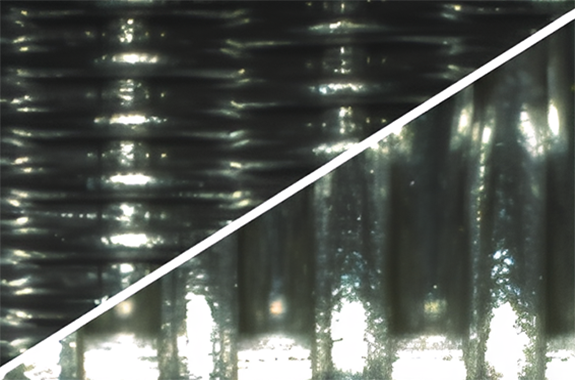

The plain weave with tightly packed horizontal lines

enhances durability, while the three-dimensional structure provides high capture performance at high speeds.

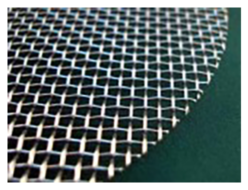

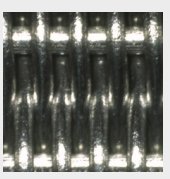

Plain woven weave:

A weaving method in which the horizontal wires are tightly weaved like a tatami mat. The vertical wires can be thick, making them strong and suitable for use in environments where pressure resistance is required. When the wire mesh is viewed from the front, there are no visible gaps, and it has a higher pressure loss than plain weave, so it is often used for filtering liquids. The tightly woven wire structure means there is less bending and deformation of the wires, resulting in stable performance.

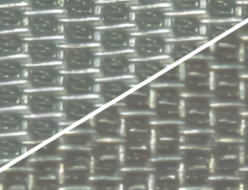

Reverse

plain tatami weave: A weaving method in which the relationship between the warp and weft lines of the plain tatami weave is reversed. This is used in screen changers, etc. because the mountain shape of the wire mesh continues in the long side direction. It is used in applications where the strict direction of the wire mesh surface is important.

This is a weaving method that balances the vertical and horizontal lines of the Hi-Flo

plain tatami weave to an extreme degree. The thick vertical lines ensure strength, while the horizontal lines are made very thin, achieving high permeability, as the name suggests. It is suitable for use in environments where you want to increase the capture rate without increasing pressure loss.

Specification

| Code | mesh | Micron (nominal μm) | Absolute μm | Porosity | Weight kg/m2 | Material thickness % |

|---|---|---|---|---|---|---|

| SPW 34 | 80×30 | twenty five | 32-36 | 51 | 0.98 | 0.25 |

| SPW 40 | 80×400 | 36 | 36-45 | 55 | 0.82 | 0.23 |

| SPW 45 | 2/50×250 | 30 | 42-48 | 1.15 | 0.31 | |

| SPW 63 | 50×250 | 40 | 56-63 | 61 | 1 | 0.32 |

| SPW 71 | 50×280 | 45 | 71-75 | 61 | 1 | 0.32 |

| SPW 75 | 40×200 | 56 | 75-80 | 59 | 1.3 | 0.4 |

| SPW100 | 30×150 | 63 | 100-112 | 60 | 1.6 | 0.5 |

| SPW 125 | 24×110 | 80 | 112-125 | 49 | 2.7 | 0.67 |

| SPW 140 | 22×140 | 140-170 | 60 | 2.1 | 0.66 | |

| SPW 160 | 20×160 | 160-180 | 61 | 1.55 | 0.5 | |

| SPW 180 | 20×150 | 170-190 | 63 | 1.6 | 0.55 | |

| SPW 200 | 16×120 | 200-210 | 62 | 1.95 | 0.64 | |

| SPW 240 | 14×110 | 220-240 | 62 | 2.15 | 0.72 | |

| SPW 250 | 12x 95 | 240-260 | 63 | 2.3 | 0.79 | |

| SPW 260 | 14x 88 | 280-300 | 48 | 3.15 | 0.76 | |

| SPW 280 | 10x 90 | 270-290 | 66 | 2.5 | 0.93 | |

| SPW300 | 12x 64 | 280-300 | 57 | 4.1 | 1.21 | |

| SPW 360 | 8x 85 | 330-350 | 66 | 2.5 | 0.93 | |

| RPD 15 | 720×150 | 15 | 16-20 | 45 | 0.65 | 0.15 |

| RPD 17 | 630×130 | 17 | 20-24 | 51 | 0.85 | 0.22 |

| RPD 25 | 600×100 | 25 | 34-38 | 56 | 0.8 | 0.23 |

| RPD 40 | 290×75 | 40 | 53-58 | 51 | 1.55 | 0.4 |

| RPD 60 | 175×50 | 60 | 67-75 | 47 | 2.4 | 0.57 |

| RPD 80 | 130×35 | 80 | 95-105 | 49 | 3.1 | 0.77 |

| RPD 85 | 175×37 | 85 | 100-106 | 54 | 2.1 | 0.57 |

| RPD 90 | 170×40 | 90 | 106-118 | 54 | 2.1 | 0.57 |

| RPD 400 | 84×14 | 450-530 | 62 | 3.5 | 1.15 | |

| RPD 500 | 80×14 | 560-630 | 64 | 3.4 | 1.18 | |

| HIFLO 20 | 165×1100 | 19-20 | 61 | 0.29 | 0.09 | |

| HIFLO 25 | 80×1020 | 22-25 | 63 | 0.49 | 0.17 | |

| HIFLO 30 | 80×0820 | 28-30 | 67 | 0.41 | 0.16 | |

| HIFLO 36 | 80×0700 | 34-36 | 64 | 0.6 | 0.21 | |

| HIFLO 40 | 80×0525 | 38-40 | 64 | 0.53 | 0.19 | |

| HIFLO 45 | 70×0450 | 42-45 | 58 | 0.8 | 0.24 | |

| HIFLO 50 | 53×0480 | 48-50 | 64 | 0.72 | 0.25 | |

| HIFLO 70 | 53×0380 | 67-70 | 60 | 0.82 | 0.26 |