ISHIKAWA

ISHIKAWA Punching Metal

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

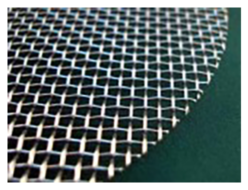

Punching metal (also called perforated metal. This is the origin of the name of Ishikawa Kanaami Design Punching Metal, Perforart)

Ishikawa Wire Netting’s perforated metals are available in two types: “custom-made products,” which allow you to order products with the optimum processing for your application, including not only the choice of material but also the thickness, hole diameter, aperture rate, flatness, width, and length, and “fixed-length products,” whose hole diameter and dimensions are preset.

We stock custom-made punched metal materials with round holes, square holes, long holes, etc. Please refer to the list of custom-made products for the hole diameters and pitches we handle. We will also consider processing patterns that are not listed in the list of custom-made products. Please feel free to contact us.

Perforated metal standard-length products are products with preset hole diameters, pitches, and dimensions. They are supplied as aluminum blanks, and the standards are unified, so we can respond to short delivery times. Please see the list of standard-length products.

For details on “Design Punching Panels,” which allow you to express designs using punched holes, please see Design Punching Panels Perforart®.

Second Processing

Ishikawa Wire Netting can perform secondary processing on custom-made punched metal products. Since secondary processing is carried out in our own factory, we can consistently manage quality and shorten delivery times for quick delivery.

Main processing examples

- Mounting hole processing (simple hole, loose hole, burring)

- Processing irregular cutouts, processing holes for doorknobs, etc.

- Diagonal panel processing for staircase slopes, and irregular panel processing for circles, etc.

- Bending

Box bending, R bending, caulking support (hat bend), corner bending (outer corners, inner corners, etc.), crushing (hemming)

Z-bending, L-bending, U-bending (U-shaped bending), and other compound bending processes welding- Joint welding, box processing welding, other welding

Stud pin welding

We will also consider processing if requested.

- Joint welding, box processing welding, other welding

Surface Finish

- Raw materials (custom-made products, fixed-length materials)

- The metal material is as is. Iron and aluminum are susceptible to corrosion and require some kind of surface finishing. If you would like to finish them yourself, we can provide them as raw materials.

Please note that standard length materials are provided as raw aluminum materials.

- The metal material is as is. Iron and aluminum are susceptible to corrosion and require some kind of surface finishing. If you would like to finish them yourself, we can provide them as raw materials.

- Paint finish (custom product)

- The surface of the material is finished with paint. The advantages of a paint finish are:

- You can color it as you like

- Prevents corrosion

- It is possible to achieve a finish that blends seamlessly with other materials such as plastic.

There are various finishes available, such as acrylic paint, fluorine paint, urethane paint, photocatalyst paint, etc. We will consult with you about the finish according to your request.

- The surface of the material is finished with paint. The advantages of a paint finish are:

- Anodized coating (anodized aluminum) (custom-made product)

- This is a finish exclusively for aluminum. The surface is electrically oxidized to create an oxide film. The oxide film is hard and can give the material durability. Because it is an oxide film, the texture of the metal can be kept as it is. Silver and stainless colors (close to brown) are common, but recently various colored anodizing has also been used for automobile parts.

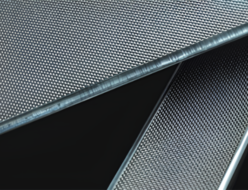

- Polished (stainless steel) (custom order product)

- This is a finish exclusively for stainless steel, which is almost never corroded even when left as is. Finishes include 2D, 2B, and HL. We can provide a variety of finishes, from mirror finishes to hairline and almost no gloss finishes, making effective use of the metallic texture.

Please contact us to discuss the best finish for you. We will work with you to find the right one.

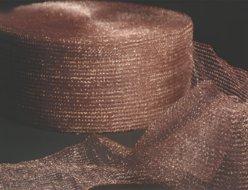

Materials

We process custom-made products using cold-rolled and hot-rolled steel sheets, galvanized steel sheets, surface-treated steel sheets, PVC steel sheets, high-tensile steel sheets, stainless steel sheets, aluminum, and colored aluminum.

If you have any other desired materials, please let us know. We will consider processing them.

The standard length material is aluminum A1050P-H24 plain.

Material shape

The maximum size of a sheet of material that can be processed into custom-made products is 1,585 mm wide and 4,000 mm long. For larger sizes, there are methods such as dividing the panel into multiple pieces, so please feel free to contact our experienced sales staff.

Punching Metal Standards Table

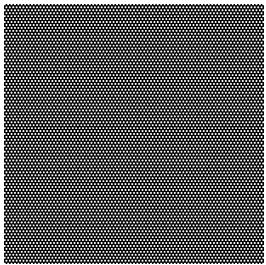

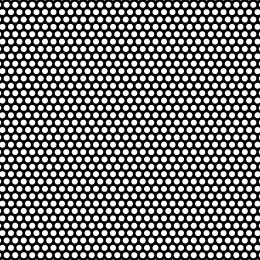

ROUND PERFORATION (Round hole punched plate)

| Part Number | pattern | Opening rate | |

|---|---|---|---|

| 60 DEGREE PATTERN (60° staggered plate) | |||

| R005011 | 0.5φx1.1P | 18.70% |

| R006012 | 0.6φx1.2P | 22.60% |

| R008015 | 0.8φx1.5P | 25.70% |

| R00805 | 0.8φx5P | 2.30% | |

| R01015 | 1φx1.5P | 40.20% |

| R0102 | 1φx2P | 22.60% |

| R0108 | 1φx8P | 1.40% |

| R01503 | 1.5φx3P | 22.00% |

| R01504 | 1.5φx4P | 12.50% |

| R02026 | 2φx2.6P | 48.50% |

| R0203 | 2φx3P | 40.20% |

| R02032 | 2φx3.2P | 35.20% |

| R02035 | 2φx3.5P | 29.60% |

| R0204 | 2φx4P | 22.60% |

| R02045 | 2φx4.5P | 17.80% |

| R025035 | 2.5φx3.5P | 46.20% |

| R02504 | 2.5φx4P | 35.40% |

| R02505 | 2.5φx5P | 22.60% |

| R02506 | 2.5φx6P | 15.50% |

| R0304 | 3φx4P | 50.80% |

| R03045 | 3φx4.5P | 40.20% |

| R0305 | 3φx5P | 32.50% |

| R0306 | 3φx6P | 22.60% |

| R0405 | 4φx5P | 57.90% |

| R0406 | 4φx6P | 40.20% |

| R0407 | 4φx7P | 29.60% |

| R0408 | 4φx8P | 22.60% |

| R04506 | 4.5φx6P | 50.00% |

| R045065 | 4.5φx6.5P | 43.30% |

| R0506 | 5φx6P | 62.80% |

| R0507 | 5φx7P | 46.10% |

| R0508 | 5φx8P | 35.40% |

| R0509 | 5φx9P | 27.90% |

| R0510 | 5φx10P | 22.60% |

| R0608 | 6φx8P | 50.90% |

| R0609 | 6φx9P | 40.20% |

| R0610 | 6φx10P | 32.60% |

| R0612 | 6φx12P | 22.60% |

| R0710 | 7φx10P | 44.40% |

| R0711 | 7φx11P | 36.60% |

| R0712 | 7φx12P | 30.70% |

| R0810 | 8φx10P | 57.90% |

| R0812 | 8φx12P | 40.20% |

| R0815 | 8φx15P | 25.70% |

| R0911 | 9φx11P | 60.50% |

| R0913 | 9φx13P | 43.30% |

| R0915 | 9φx15P | 32.50% |

| R1012 | 10φx12P | 62.80% |

| R1013 | 10φx13P | 53.60% |

| R1015 | 10φx15P | 40.20% |

| R1215 | 12φx15P | 57.90% |

| R1218 | 12φx18P | 40.20% |

| R1520 | 15φx20P | 51.00% |

| R1530 | 15φx30P | 22.60% |

| R1830 | 18φx30P | 32.50% |

| R2028 | 20φx28P | 46.10% |

| R2030 | 20φx30P | 40.20% |

| R2535 | 25φx35P | 46.20% |

| R3040 | 30φx40P | 50.80% |

| R4050 | 40φx50P | 57.90% |

| R50 | 50φ | |

| 45 DEGREE PATTERN (45° staggered plate) | |||

| RD01805 | 1.8φx5P | 20.30% |

| RD024067 | 2.4φx6.7P | 20.10% |

| RD02508 | 2.5φx8P | 15.30% |

| RD0818 | 8φx18P | 31.00% |

| RD1020 | 10φx20P | 39.20% |

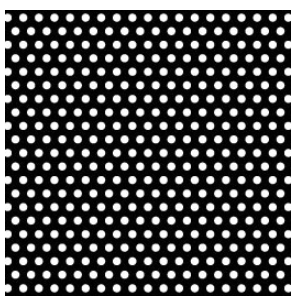

| STRAIGHT LINE PATTERN (Straight (flat)) row cutout plate | |||

| RS0204 | 2φx4P | 19.60% |

| RS0307 | 3φx7P | 14.40% |

| RS0510 | 5φx10P | 19.60% |

| RS0520 | 5φx20P | 4.90% |

| RS0812 | 8φx12P | 34.80% |

| RS0813 | 8φx13P | 29.70% |

| RS1015 | 10φx15P | 34.80% |

| RS1020 | 10φx20P | 19.60% |

| RS1520 | 15φx20P | 44.10% |

| RS2030 | 20φx30P | 34.80% |

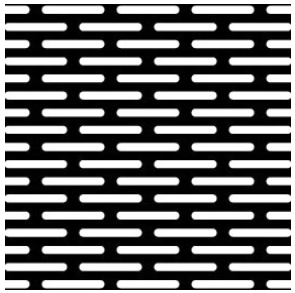

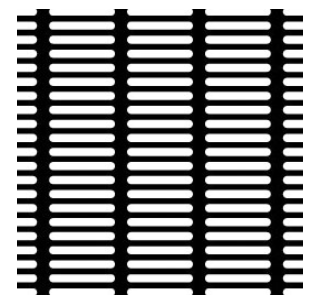

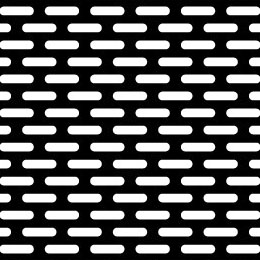

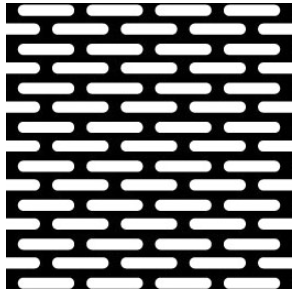

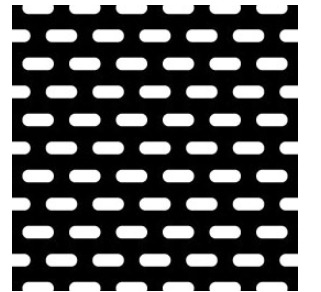

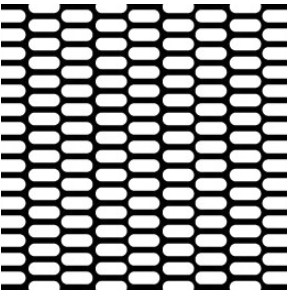

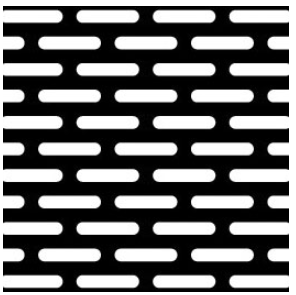

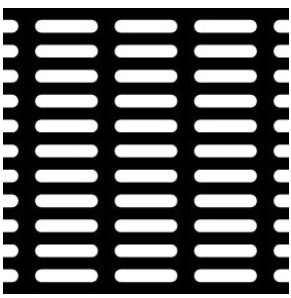

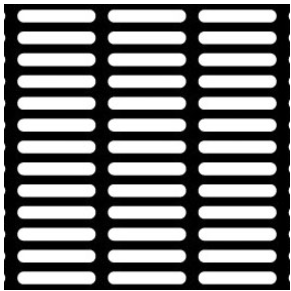

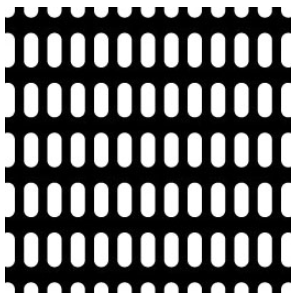

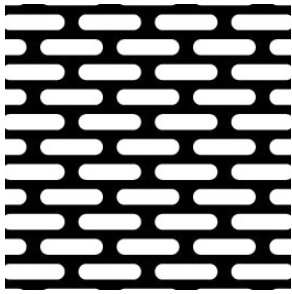

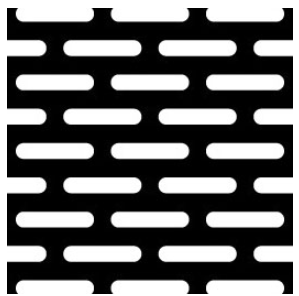

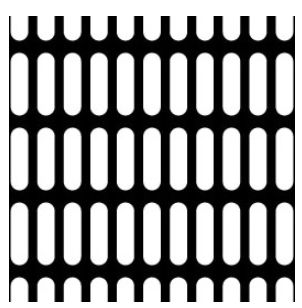

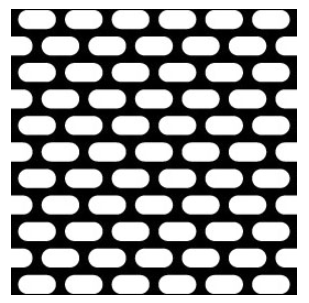

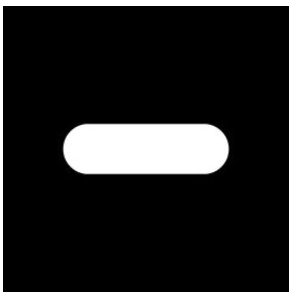

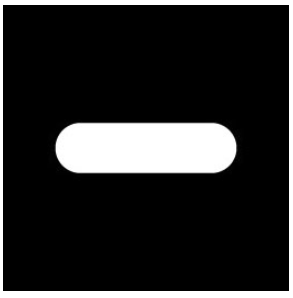

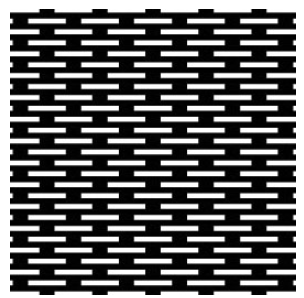

LONG PERFORATION (Long hole punch plate)

| Part Number | pattern | Opening rate | |

|---|---|---|---|

| SLOT (Oval hole punched plate) | |||

| SL0112 | 1×12 | |

| SL0113 | 1×13 | |

| SL0125 | 1×25 | |

| SL01510 | 1.5×10 | |

| SL01515A | 1.5×15 | |

| SL01515B | 1.5×15 | |

| SL01518 | 1.5×18 | |

| SL0212 | 2×12 | |

| SL0215 | 2×15 | |

| SL0220 | 2×20 | |

| SL0224 | 2×24 | |

| SL02512 | 2.5×12 | |

| SL02520 | 2.5×20 | |

| SL02521 | 2.5×21 | |

| SL02524 | 2.5×24 | |

| SL0310 | 3×10 | |

| SL0312 | 3×12 | |

| SL0320A | 3×20 | |

| SL0320B | 3×20 | |

| SL0333 | 3×33 | |

| SL03518 | 3.5×18 | |

| SL0410A | 4×10 | |

| SL0410B | 4×10 | |

| SL0412 | 4×12 | |

| SL0420 | 4×20 | |

| SL0421 | 4×21 | |

| SL0425 | 4×25 | |

| SL0428 | 4×28 | |

| SL04511 | 4.5×11 | |

| SL0520A | 5×20 | |

| SL0520B | 5×20 | |

| SL0525A | 5×25 | |

| SL0525B | 5×25 | |

| SL05520 | 5.5×20 | |

| SL0611 | 6×11 | |

| SL0612 | 6×12 | |

| SL0620 | 6×20 | |

| SL0709 | 7×9 | |

| SL0720 | 7×20 | |

| SL0725 | 7×25 | |

| SL0730 | 7×30 | |

| SL0830A | 8×30 | |

| SL0830B | 8×30 | |

| SL0832 | 8×32 | |

| SL0846 | 8×46 | |

| SL1020 | 10×20 | |

| SL1030 | 10×30 | |

| SL1045 | 10×45 | |

| SL1075 | 10×75 | |

| SL1135 | 11×35 | |

| SL1136 | 11×36 | |

| SL1653 | 16×53 | |

| SL1658 | 16×58 | |

| SL1876 | 18×76 | |

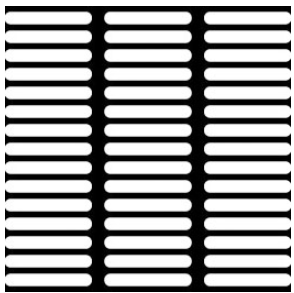

| OBLONG (Oblong hole punch plate) | |||

| OB01512 | 1.5×12 | |

| OB01530 | 1.5×30 | |

| OB0421 | 4×21 | |

| OB0840 | 8×40 | |

| OB1644 | 16×44 | |

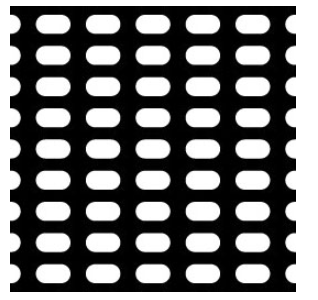

SQUARE PERFORATION (Square hole punching plate)

| Part Number | pattern | Opening rate | |

|---|---|---|---|

| SQUARE (Square hole punch plate) | |||

| SD025035 | D2.5×3.5 | 51% |

| SD0305 | D3x5 | 36.00% |

| SD03506 | D3.5×6 | 34.00% |

| SD06095 | D6x9.5 | 39.80% |

| SD0710 | D7x10 | 49.00% |

| SD0711 | D7x11 | 40.40% |

| SD0811 | D8x11 | 52.80% |

| SD0915 | D9x18 | 36.00% |

| SD1013 | D10x13 | 59.00% |

| SD10517 | D10.5×17 | 38.00% |

| SR0407 | 4□x7P | 32.60% |

| SR0508 | 5□x8P | 39.00% |

| SS02035 | 2□x3.5P | 32.60% |

| SS0204 | 2□x4P | 25.00% |

| SS02504 | 2.5□x4P | 39.00% |

| SS0305 | 3□x5P | 36.00% |

| SS03506 | 3.5□x6P | 34.00% |

| SS0407 | 4□x7P | 32.60% |

| SS05075 | 5□x7.5P | 44.40% |

| SS0508 | 5□x8P | 39.00% |

| SS0609 | 6□x9P | 44.40% |

| SS0710 | 7□x10P | 49.00% |

| SS0711 | 7□x11P | 40.40% |

| SS0810 | 8□x10P | 64.00% |

| SS0813 | 8□x13P | 38.00% |

| SS1013 | 10□x13P | 59.00% |

| SS1015 | 10□x15P | 44.40% |

| SS1520 | 15□x20P | 64.00% |

| SS2030 | 20□x30P | 44.40% |

| SS2530 | 25□x30P | 69.00% |

| SS2538 | 25□x38P | 43.00% |

| SS3040 | 30□x40P | 56.20% |

| SS40 | 40□ | 41.60% |

| SS50 | 50□ | 37.50% |

DIAMOND (Diamond punched plate)

| Part Number | pattern | Opening rate | |

|---|---|---|---|

| DD0610 | 6×10 | |

| DD0714A | 7×14 | |

| DD0714B | 7×14 | |

| DD1017 | 10×17 | |

| DD1121 | 11×21 | |

| DD1528 | 15×28 | |

| DD1729 | 17×29 | |

| DD2239 | 22×39 |

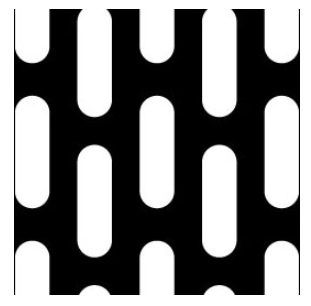

DECORATIVE PERFORATION (Decorative perforation plate)

| Part Number | pattern | Opening rate | |

|---|---|---|---|

| DECORATIVE (Decorative hole punch plate) | |||

| DC049 | ||

| DC050 | ||

| DC051 | ||

| DC052 | ||

| DC053 | ||

| DC054 | ||

| DC057 | ||

| DC194 | ||

| DC570 | ||

| DC571 | ||