ISHIKAWA

ISHIKAWA Rolled Wire Mesh

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

Reliable Filtration Media and Filter Media Using Rolled Wire Mesh. Various combinations are possible according to your usage.

- Uniform filtration accuracy is required

- Strong pressure resistance is needed

- Repeated regeneration is necessary

- When wanting to reduce pressure loss

- When removing gel from polymers or refining the gel into fine particles

We conduct differential pressure (pressure loss) tests using extruders according to your requirements. We carefully examine conditions such as injection methods, kneading methods, and additives to consider the optimal combination. You can select from the filter media specifications table.

Three Types of Rolled Wire Mesh

Ishikawa Wire Mesh offers three types of rolled wire mesh and provides screens.

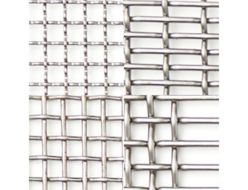

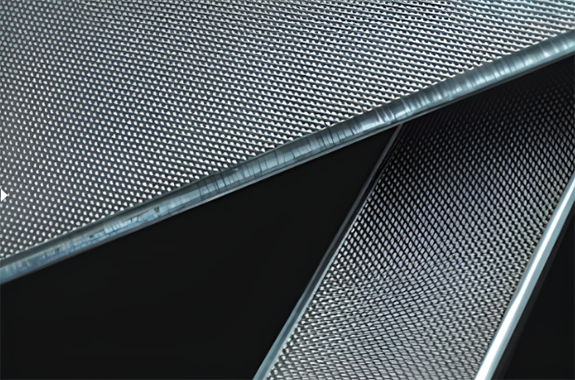

Type A: Rolled Wire Mesh (Calendar Screen / CS)

This woven wire mesh has undergone rolling processing. By applying rolling processing, we firmly combine the intersections of the wires, maintaining high strength with no open gaps. Additionally, you can control the thickness according to the rolling conditions. Furthermore, as the surface becomes flatter, the open gap size decreases even with the same mesh. When used as filter media, the open gap size is verified through bubble point tests. The term “calendar” in calendar screens originally means a polishing process. The rolling conditions give the wire mesh a sheen, making it usable for decorative purposes as well.

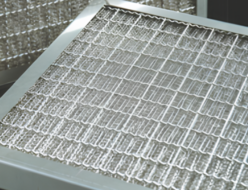

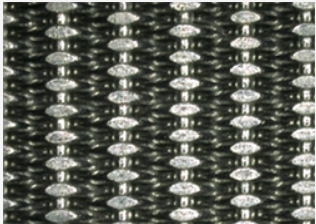

Type B: Laminated Rolled Wire Mesh (Laminated Calendar Mesh / LCM)

We use strong woven wire mesh with a thick wire diameter that has undergone rolling processing as a reinforcing mesh. To ensure high pressure resistance and durability, we employ a multi-layer structure with a guarantee mesh in between. It withstands backwashing and can be repeatedly cleaned. The difference from sintering processing is that we laminate the woven wire mesh through resistance welding (spot welding).

- Type B-1

- Pressing and crushing the outer edge of Type B improves seam performance, preventing leakage from the outer edge.

- Type B-2

- Attaching a frame to the outer edge of Type B improves seam performance, preventing leakage from the outer edge.

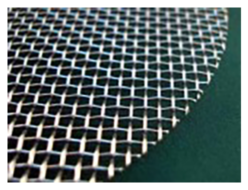

Type C: Laminated Rolled Wire Mesh & Fiber Cloth (LCM&F) Using strong woven wire mesh with thick wire diameter that has undergone rolling processing as a reinforcing mesh, a multi-layer structure with a guarantee mesh and metal non-woven fabric in between ensures high pressure resistance and durability. It withstands backwashing and can be repeatedly cleaned. The difference from sintering processing is that the woven wire mesh is laminated through resistance welding (spot welding).

- Type C-1

- Pressing and crushing the outer edge of Type C improves seam performance, preventing leakage from the outer edge.

- Type C-2

- Attaching a frame to the outer edge of Type C improves seam performance, preventing leakage from the outer edge.