ISHIKAWA

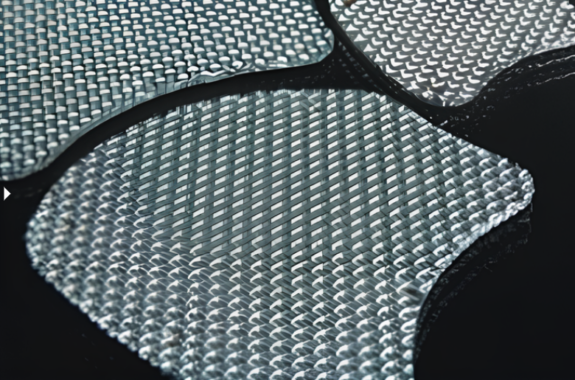

ISHIKAWA Sintered Wire Mesh

Product Made In Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

Model: Sintered Wire Mesh

Sintered Metal Mesh

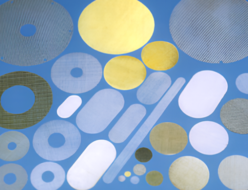

Reliable filter material and filter media using sintered metal mesh. Various combinations are possible depending on your application When :

- Uniform filtration accuracy is required

- Strong pressure resistance is needed

- Repeated regeneration is necessary

- Pressure loss needs to be reduced

- Removing or granulating gels in polymers

We will conduct differential pressure (pressure loss) tests using an extruder upon request. We will consider the optimal combination by examining conditions such as the input method, kneading method, and additives. You can select from the filter media specification table.

Four types of sintered metal mesh

Ishikawa Wire Mesh offers four types of sintered metal mesh and screens.

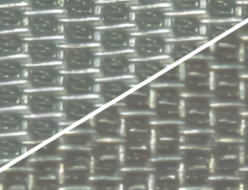

Type A: Sinter Metal Wire Cloth (SMWC)

Sintered woven wire mesh. By maintaining the woven wire mesh at temperatures around the metal’s melting point for a certain period, crystals form across the contact points within the metal structure, resulting in complete integration. This process maintains high strength without opening the mesh and prevents expansion due to pressure, while also preventing wire unraveling. Uniform accuracy is maintained until the wire breaks under pressure. However, due to heat treatment, it becomes more flexible compared to before heat treatment. It is similar to a welded state, so it has less flexibility in mesh size and is prone to tearing or breaking under high pressure when used alone.

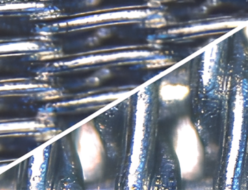

Type B: Sinter Metal Fiber Cloth (SMFC)

Sintered metal fiber. Metal fibers are opened into a web and sintered under controlled high-temperature conditions. This ensures that contact points between fibers are integrally bonded. This maintains high strength without opening the mesh and prevents expansion due to pressure. However, as it is a very thin material like paper, it is flexible and prone to folding, tearing, or breaking under high pressure when used alone.

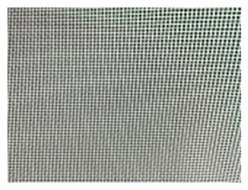

Type C: Laminated Sinter Mesh (LSM)

Sintered woven wire mesh of Type A. When used alone, it is prone to folding, tearing, or breaking under high pressure. However, by using a thicker, stronger woven wire mesh as a reinforcement mesh and incorporating a guarantee mesh in a multi-layer structure, high pressure resistance and durability are ensured, making it resistant to backwashing and allowing for repeated cleaning.

Type D: Laminated Sinter Mesh & Fiber Cloth (LSM&F)

Sintered laminated woven wire mesh and nonwoven fabric of Type A and Type B. When used alone, Type A and Type B are prone to folding, tearing, or breaking under high pressure. However, by using a thicker, stronger woven wire mesh as a reinforcement mesh and incorporating a guarantee mesh and metal nonwoven fabric in a multi-layer structure, high pressure resistance and durability are ensured, making it resistant to backwashing and allowing for repeated cleaning.