ISHIKAWA

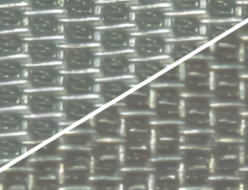

ISHIKAWA Twill and Reverse Weave Woven Wire Mesh

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co.,Ltd.

Twill weave with tightly packed wefts.

The most dense and durable woven wire mesh that can withstand high pressure.

■ Twill Tatami Weave A weaving method in which the horizontal lines of

plain weave cross over two vertical lines, just like twill weave. The bending angle of the horizontal lines is shallow, allowing the use of thicker lines, which increases the strength of the wire mesh, and the horizontal lines are tightly attached, which increases the filtration accuracy. This type of woven wire mesh is particularly suitable for environments that require strength. When even greater strength is required, we use a double warp specification in which the vertical lines are doubled.

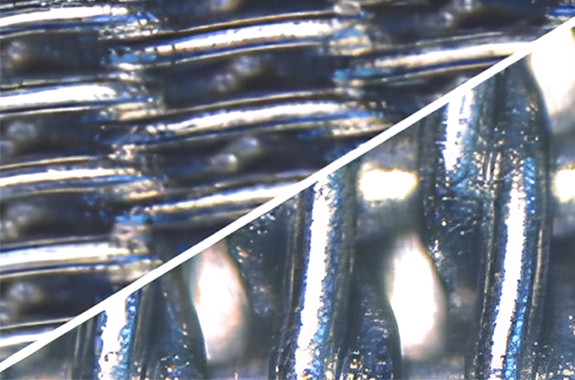

Reverse twill

Tatami weave: This is a twill tatami weave with the warp and weft lines reversed. It is more suitable for environments that require strength and filtration precision than reverse plain tatami weaves. It has an excellent smoothness of the wire mesh surface. Like reverse plain tatami weave, we use it in applications where the strict direction of the wire mesh surface is important..

Specifications

Calculating the particle size that passes through is very complicated since the gaps in the wire mesh are in the shape of a diagonally distorted triangle. To understand the performance, we consider not only theoretical values but also actual values from glass bead tests, bubble point tests, pressure loss tests, etc. Since the linear density of the actual wire mesh is not constant, we use plain weave in addition to it to control the particle size that passes through.

We call tatami weave “mesh = vertical line diameter x horizontal line diameter.”

| Code | mesh | Micron (nominal μm) | Absolute μm | Porosity % | Weight kg/m2 | Material thickness (mm) |

|---|---|---|---|---|---|---|

| DTW 4 | 425×2800 | < 1 | 5-6 | twenty five | 0.36 | 0.06 |

| DTW 6 | 375×2300 | 1 | 6-7 | 39 | 0.39 | 0.08 |

| DTW 8 | 325×2300 | 2 | 7-8 | 34 | 0.47 | 0.09 |

| DTW 9 | 260×1550 | 3 | 8-10 | 29 | 0.68 | 0.12 |

| DTW 10 | 250×1400 | 4 | 11-12 | 29 | 0.68 | 0.12 |

| DTW 12 | 200×1400 | 5 | 11-13 | 33 | 0.75 | 0.14 |

| DTW 14 | 130×700 | 8 | 13-15 | 28 | 1.6 | 0.28 |

| DTW 16 | 200×1120 | 9 | 15-17 | 25 | 0.95 | 0.16 |

| DTW 18 | 165×1400 | 10 | 15-18 | 41 | 0.7 | 0.15 |

| DTW 20 | 165×1100 | 12 | 20-21 | 29 | 0.9 | 0.16 |

| TW 36 | 80×700 | 25 | 34-36 | 42 | 1.2 | 0.26 |

| DTW 71 | 40×560 | 50 | 71-80 | 45 | 1.7 | 0.39 |

| DTW 95 | 30×360 | 80 | 95-106 | 39 | 2.6 | 0.54 |

| DTW 100 | 30×250 | 100-112 | 38 | 3.2 | 0.65 | |

| DTW 106 | 20×260 | 100-120 | 42 | 3.1 | 0.67 | |

| DTW 112 | 28×560 | 106-112 | 47 | 1.95 | 0.46 | |

| DTW 118 | 24×300 | 112-118 | 43 | 2.85 | 0.63 | |

| TRD 75 | 400×120 | 75 | 75-80 | 62 | 0.73 | 0.24 |

| TRD 125 | 260×40 | 125 | 112-125 | 54 | 2.25 | 0.62 |

| TRD 400 | 132×17 | 400-450 | 57 | 4.65 | 1.35 | |

| TRD 500 | 72×15 | 500-600 | 57 | 6.35 | 1.85 |