ISHIKAWA

ISHIKAWA Ultrasonic Vibration Sieve

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co., Ltd.

We propose combinations of wire mesh and equipment tailored to your company’s situation

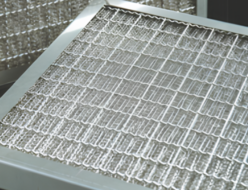

Ishikawa Wire Mesh provides advanced technology related to wire mesh, such as the “ultrasonic vibrating sieve.” From the perspective of a specialized wire mesh manufacturer, we propose the best matching of ultrasonic transducers and screens.

We adopt a sweep vibration method, which significantly reduces the setup effort that was difficult with the traditional single-wavelength resonance method of rings. This revolutionary product meets many on-site needs, such as reducing machine downtime and easy skill inheritance.

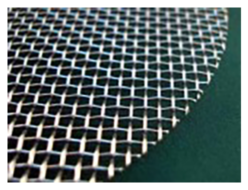

The composite frequency vibration uniformly amplifies the entire screen, improving sieving efficiency. By preventing stress concentration at specific parts of the wire mesh and using a system that does not require tapping balls, the screen’s lifespan can be extended, and productivity can be improved.

Effects

- Stable feed

- Prevents powder bridging, reduces friction resistance on hopper sidewalls

- Increased sieving efficiency

- Speeds up, increases processing capacity by 1.5 times with the vibrator attached

- Downsized sieving

- Miniaturizes and lightens equipment, lowers screen costs used

- Upsized effect

- Exhibits performance equivalent to large-area screens due to high processing capacity

- Extended wire mesh lifespan

- Prevents screen damage, mesh opening, and mesh collapse due to long-term vibration

- Extended wire mesh lifespan

- No mixing of different materials due to the absence of tapping balls

Target particle size and effects

- Effective for particles between 20 microns and 500 microns

- Significant increase in sieving efficiency for particles between 150 microns and 500 microns

- High effectiveness in preventing clogging for particles at 20 microns and 150 microns

Applications

- Fine powders: Titanium oxide, talc, calcium carbonate, abrasives, powder coatings, foundation, toner, ceramic powder, precious metal powders, lactose, powdered sugar, cornstarch, flour, food additives, pharmaceuticals, etc.

Since it can be installed later on existing machines, smooth introduction is possible. Detachment is very easy. We also have a handheld ultrasonic cleaning system for screen maintenance. If you have a test sample for sieving, please feel free to contact us.