ISHIKAWA, Japan

ISHIKAWA Woven Wire Mesh

Made in Japan

Manufacturer: ISHIKAWA WIRE NETTING Co.,Ltd.

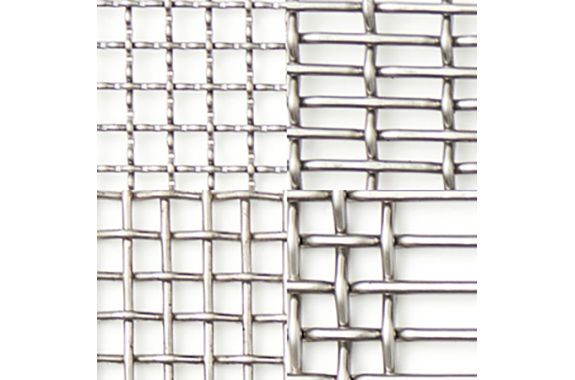

Crimped Wire Mesh

Crimped wire mesh is made by bending the wires into wavy shapes and weaving them together vertically and horizontally. The mesh does not deform due to the fixed peaks and valleys of the waves. With thicker wires, crimped wire mesh is stronger than plain woven wire mesh.

In addition to the standard “standard crimped wire mesh,” we also offer customized products such as “double crimped wire mesh,” “flat top wire mesh,” and “ton cap wire mesh.” Depending on the application, the suitable material and size will vary, so please feel free to contact us for specific advice.

Main Applications:

Construction, Industrial, Mining, Various machinery, Protection, Decoration, Threshing machines, Concrete protection, Warehouse shelves, Partitions, Grilling

Main Wire Types:

Stainless steel wire, Galvanized wire, Iron wire, Brass wire

Crimped Wire Mesh (Standard Type) – In Stock.

This is the standard type of crimped wire mesh. As it is available in stock, we can ensure speedy delivery.

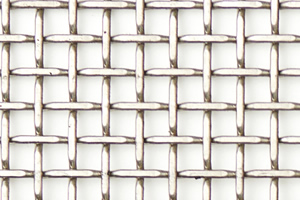

Double crimped wire mesh (Made to order)

This mesh is made by uniformly bending and weaving the vertical and horizontal wires together. It prevents the wires from moving during use, allowing the mesh to maintain accurate apertures for a long period. It has a similar structure to “plain woven wire mesh,” where the vertical and horizontal wires are woven alternately at regular intervals.

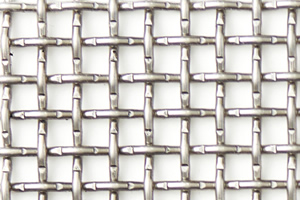

Flat top wire mesh (Made to order)

Wire mesh with one flat side (surface). The flat surface prevents wear and enhances screening efficiency due to the absence of unevenness.

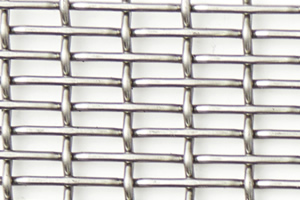

Ton Cap wire mesh (Made to order)

Wire mesh woven into a rectangular pattern. Its high open area increases screening efficiency.

Lock crimp wire mesh (Made to order)

This wire mesh is woven using pre-crimped wires. The wires lock together, allowing the mesh to maintain its structure and enabling the use of thin wires to create large openings. It has no front or back side and is used for screening coarse particles.

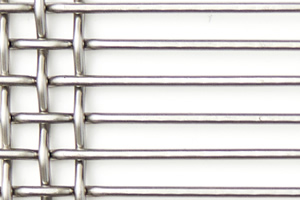

Tie rod wire mesh (Made to order)

This wire mesh features rectangular openings, providing a high open area and large flow-through space, which enhances screening efficiency. Additionally, particles slightly larger than the mesh openings are caught by two wires, preventing clogging. It is suitable for vibrating screens and various other sieving applications.

Contrast wave mesh wire mesh

This type of screen is woven by fixing wavy wires with flat wires. It utilizes secondary vibrations, causing the vertical wires to vibrate alternately in opposite directions, making it ideal for preventing clogging.