- Home

- Products

- KAJI TECHNOLOGY KJ Series Compressors For PET Bottle Molding Medium/Large Capacity Models

KAJI TECHNOLOGY CORPORATION

KAJI TECHNOLOGY KJ Series Compressors For PET Bottle Molding Medium/Large Capacity Models

Manufacturer: KAJI TECHNOLOGY CORPORATION

Made in Japan

Model: KJ Series (KJ-016, KJ-017, KJ-018, KJ-019, KJ-020)

Feature of KJ Series

High Efficiency, Energy Savings, and Low Running Costs

We focus on delivering high efficiency, energy savings, and easy maintenance. Our “Screw & Booster system” compressor ensures durability, allowing for extended continuous operation, longer maintenance cycles, and fewer consumable parts. Its compact design also provides flexibility for various factory layouts , adapting easily to meet client requirements.

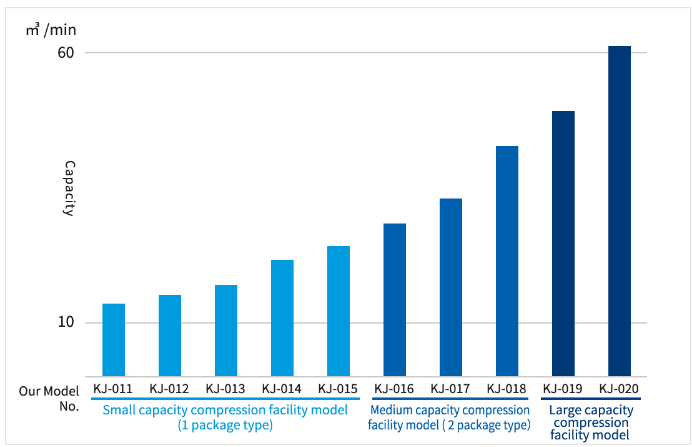

Extensive Product Lineup to Support Different Capacities

To meet the diverse air volume needs for PET bottle molding, we offer a lineup of 10 models that can boost air pressure up to 4.5 MPa, ensuring optimal model selection. This includes 5 models for small capacity, 3 for medium capacity, and 2 for large capacity applications.

Specifications

| Our Model No. | KJ-016 | KJ-017 | KJ-018 |

|---|---|---|---|

| Discharge volume(m3/min) | 25.0~ | → | → |

| Suction Air conditions | 0~35℃ RH: Less than 75% | → | → |

| Discharge conditions (Supply conditions) | (3.6) ~4.5MPa Less than 45℃ | → | → |

| Dew point of supplied air (Under atmospheric pressure) | Less than −30℃ | → | → |

| Installing location | Indoors (Non-explosion proof area) | → | → |

| Main power supply (3Φ) | 400V×50Hz 440V×60Hz (3000V×50Hz) (3300V×60Hz) (6000V×50Hz) (6600V×60Hz) | → | → |

| Manufacturing range of package type | 2 package type※ | ||

※Medium capacity type compression facility (KJ-016~018) Compactness by utilizing the integral design covering the discharge-side Dryer of the separate Screw compressor (2 package type)

| Our Model No. | KJ-019 | KJ-020 |

|---|---|---|

| Discharge volume(m3/min) | 45.0~ | → |

| Suction Air conditions | 0~35℃ RH: Less than 75% | → |

| Discharge conditions (Supply conditions) | (3.6) ~4.5MPa Less than 45℃ | → |

| Dew point of supplied air (Under atmospheric pressure) | Less than −30℃ | → |

| Installing location | Indoors (Non-explosion proof area) | → |

| Main power supply (3Φ) | 3000V×50Hz 3300V×60Hz 6000V×50Hz 6600V×60Hz | → |

| Manufacturing range of package type | ※ | |

※Large capacity compression facility (KJ-019~020) Enables layout in accordance with client’s factory layout requirements.

Related Products

-

KAJI TECHNOLOGY YD2-180-OL Medium and High Pressure Oil-Free Compressor

-

KAJI TECHNOLOGY VD3-150GH-OL Compressors For Plant-Related Business

-

KAJI TECHNOLOGY AV Series RECEIVERS Oil-Free Compressor

-

KAJI TECHNOLOGY VS-45H Water-Cooled Lubricated Compressor

-

KAJI TECHNOLOGY WH3-75 Water-Cooled Lubricated Compressor

-

KAJI TECHNOLOGY YD3-140L Water-Cooled Lubricated Compressor