KAJI TECHNOLOGY CORPORATION

KAJI TECHNOLOGY VD3-110-OL Medium and High Pressure Oil-Free Compressor

Manufacturer: KAJI TECHNOLOGY CORPORATION

Made in Japan

Model: VD3-110-OL

Feature of VD3-110-OL

High Reliability

We use only high-quality materials that undergo rigorous testing against corrosion and abrasion. Our advanced manufacturing facilities, backed by cutting-edge technologies and a robust quality control system, ensure stable performance for long-term compressor operation.

Economical and Simplified Operations

Our compressors reduce overall operational costs with streamlined operation and maintenance systems. Features like the patented Dual Control System, Multiple Operation Control System, and Integrated Control System help users easily select optimal operational conditions for specific purposes, ensuring efficiency and simplicity.

Cost-Effective Design with a Building Block System

We design standardized compressor parts such as cylinders, pistons, and valves to accommodate a wide range of specifications. The Building Block System allows for quick assembly of units based on required pressure, capacity, and operational conditions. This approach ensures reliable machines at competitive costs and faster delivery times.

Tailored Solutions for Individual Applications

We carefully select seal rings and implement anti-corrosion measures to meet the specific requirements of each gas application, ensuring durability and safety.

Interchangeable Parts for Greater Flexibility

Our compressors cover a capacity range from 3.7kW to 730kW. Most components within this range are interchangeable, allowing users to maintain compressors of various sizes with ease. This flexibility reduces the need for extensive spare part inventories while ensuring seamless operation across multiple compressor models.

Application of VD3-110-OL

- Typical example of Oil-free compressor applications

- PET bottles blowing

- Electronics

- Environment, Biogas

- Industrial automatic controls:

-Automatic measurement by precision instruments

-Automatic handling - Chemical industries:

-Agitation, filtration, pneumatic transport, suctions, and also recovery, compression, and purifications of gases. - Pharmaceutical and food industries:

-Air supply to cultivation chambers and agitation - Electronic industries:

-Gas spraying, and drying - Petrochemical industries:

-Compression and pneumatic transport - Energy industries:

-Installations for coal gasification and liquefaction, heat pump, fuel cell, etc. - Power generating plant:

-Control equipment for nuclear power stations, compression of sealing gas for nuclear power generating plant, pushing down of water level at Hydroelectric power stations. - Medical equipment:

-High pressure forming facilities - Others:

-Shock test for vehicles, clean rooms, etc.

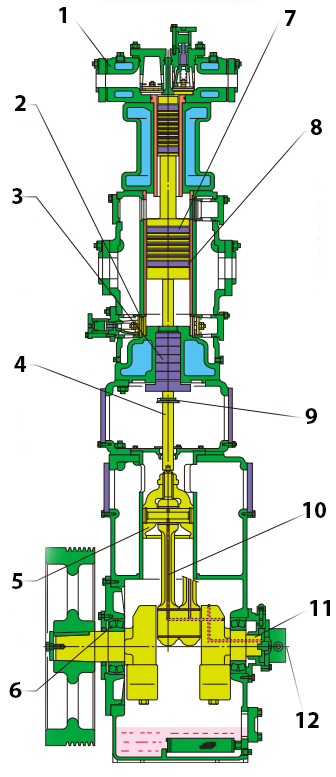

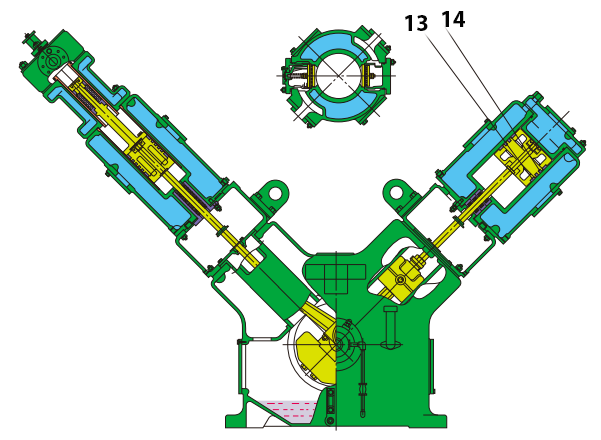

Techical drawing

- Cylinder Head: Our system includes independent sealing for both gas and cooling water sides. This design eliminates gas and cooling water leakage, ensuring efficient operation.

- Suction and Discharge Valves: We use guideless suction and discharge valves, specially treated to resist corrosion and abrasion, ensuring long-lasting performance.

- Rod Packing: The rod packing incorporates elements made from special carbon or TFE (tetrafluoroethylene) composites, stacked in a gland holder. The design uses cylinder pressure as pilot pressure to press the packing elements against the piston rod, ensuring a strong self-sealing effect and minimal leakage.

- Piston Rod: Made from high-quality carbon steel, the piston rod undergoes high-frequency induction hardening, followed by hard chromium plating and mirror finishing. This process makes it resistant to corrosion and abrasion, durable, and airtight. Its extended idle length effectively prevents oil carryover.

- Crosshead: We manufacture the crosshead from aluminum alloy or ductile cast iron to minimize reciprocating inertia force. This design reduces vibrations caused by unbalanced inertia forces.

- Main Bearing: The main bearing features a double self-aligning design with a wide margin, eliminating the need for bearing gap adjustments.

- Piston: Our pistons, made from aluminum alloy, ductile cast iron, or stainless steel, undergo special surface treatments to resist corrosion. The slightly smaller outside diameter of the piston compared to the rider ring prevents direct contact with the cylinder surface, even during piston ring erosion.

- Cylinder and Cylinder Liner: The cylinder’s running bore surface features hard chromium plating and mirror finishing to ensure superior gas and air tightness. The design minimizes erosion and gas passage resistance while extending the cooling surface to enhance gas temperature reduction. The one-piece cast cylinder and back head construction completely prevents gas or coolant leakage. Non-contact liners prevent coolant intrusion and liner corrosion.

- Oil Seal and Oil Wiper Ring: Heat- and oil-resistant synthetic rubber oil seals and oil wiper rings prevent oil vapor from the crankcase from reaching the cylinder.

- Connecting Rod: Made of ductile cast iron, the connecting rod features precision machining and includes precision metal at the big end. This eliminates the need for clearance adjustments.

- Crankshaft: The crankshaft, crafted from ductile cast iron or forged steel, undergoes precise machining. One end features a tapered design to simplify mounting and dismounting of the driving pulley.

- Lubrication System: For compressors up to 45 kW, we use a splash lubrication system, while forced lubrication with a geared pump is used for systems above 55 kW. The oil reservoir includes a strainer, relief valves, and oil pressure switches for added safety.

- Rider Ring: We use rider rings made of special carbon or TFE composites for extended service life. Endless-type rider rings offer even longer durability, as they remain unaffected by backpressure.

- Piston Ring: Our piston rings, crafted from special carbon or TFE composites, deliver exceptional resistance to leakage and abrasion, doubling the lifespan compared to previous designs.

Specifications of VD3-110-OL

4.9MPa SERIES

| Model | Cyl. Bore (mm) x No. | Stroke (mm) | No of rev. (rpm) | Piston displacement (m³/min) | Motor (kW) x (p) | Cooling water (l/min) |

|---|---|---|---|---|---|---|

| VD3-110-OL | 300×1 200×1 100×1 | 180 | 440 | 11.0 | 110×6 | 130 |

| 500 | 12.5 | 125×6 | 150 | |||

| 540 | 13.5 | 132×6 | 160 |

7.35MPa SERIES

| Model | Cyl. Bore (mm) x No. | Stroke (mm) | No of rev. (rpm) | Piston displacement (m³/min) | Motor (kW) x (p) | Cooling water (l/min) |

|---|---|---|---|---|---|---|

| VD3-110-OL | 300×1 200×1 100×1 | 180 | 390 | 9.7 | 110×6 | 130 |

| 440 | 11.0 | 125×6 | 150 | |||

| 480 | 12.0 | 132×6 | 160 |

9.8MPa SERIES

| Model | Cyl. Bore (mm) x No. | Stroke (mm) | No of rev. (rpm) | Piston displacement (m³/min) | Motor (kW) x (p) | Cooling water (l/min) |

|---|---|---|---|---|---|---|

| VD3-110-OL | 300×1 200×1 100×1 | 180 | 390 | 9.7 | 110×6 | 130 |

| 440 | 11.0 | 125×6 | 150 | |||

| 480 | 12.0 | 132×6 | 160 |

Related Products

-

KAJI TECHNOLOGY KJ Series Compressors For PET Bottle Molding Medium/Large Capacity Models

-

KAJI TECHNOLOGY YD2-45-OL Medium and High Pressure Oil-Free Compressor

-

KAJI TECHNOLOGY KL40V-11OL-RSII SF6 Gas Recovery Unit

-

KAJI TECHNOLOGY WH5A-15 Water-Cooled Lubricated Compressor

-

KAJI TECHNOLOGY YD2-220-OL Medium and High Pressure Oil-Free Compressor

-

KAJI TECHNOLOGY WH3-75 Water-Cooled Lubricated Compressor