Japan, Kaneko Sangyo

Kaneko Sangyo LM Series Magnet Float Liquid Level Gauges

Manufactuer: Kaneko Sangyo

Model: LM Series

Overview

The liquid level gauge consists of a non-magnetic indicator chamber (pipe body) and an indicator float with a built-in magnet. Additionally, it includes a rotor float. When the liquid flows into the chamber through the nozzle, the float rises and falls with the liquid level. Consequently, the float moves up and down, indicating the liquid level accurately.

At that time, we will display rotating the rotor and the rotor magnet float while suction and repulsion.

In addition, because of its good seal without the use of a pressure-resistant glass in the fluid at high risk, such as high-pressure and high-temperature fluid alkali, strong acid, flammable or toxic, odor, dirt, etc. on the fluid viscosity is relatively large, be suitable.

In white (or light liquid) red every 10mm, every green vapor 100mm, instruction color indicator, liquid level appears generally clear liquid phase (liquid or heavy).

Features of LM Series

- Built as hermetically sealed, pressure-resistant containers, these level gauges can be safely used in gas/vapor explosion hazardous areas (classes I and II).

- Safe and reliable operation owing to the use of magnetic force only.

- Varying liquid levels can be identified owing to red and white markings.

- Products certified for high-pressure services are also available.

- An explosion-proof type or ordinary-type reed switch can be attached.

Standard Specifications of LM Series

WORKING PRESSURE

1.96MPa

LIQUID TEMPERATURE

150℃

SPECIFIC GRAVITY OF LIQUID

0.7or over

VISCOSITY OF LIQUID

1.5 P or less

Max specification of LM Series

- WORKING PRESSURE

- 24.5MPa

- LIQUID TEMPERATURE

- 420℃

- SPECIFIC GRAVITY OF LIQUID

- 0.4

※General-purpose type liquid level gauges using plate glass, available in reflex and transparent.

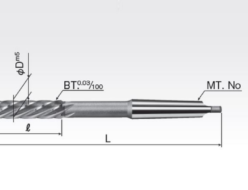

Dimension

| NOMINAL SIZE | MOUNTING LENGTH L | VISIBLE LENGHT B |

|---|---|---|

| 20 | APPOINT | APPOINT |