Japan, Kanetec

Kanetec EPT-3060F/EPT-LW1530F Permanent Electromagnetic Chuck (Standard)

Product Made in Japan

Manufacturer: Kanetec

Model: EPT-3060F/EPT-LW1530F

![]()

Application of Model EPT-3060F/EPT-LW1530F

Most suitable for highly accurate grinding such as precision grinding and slicing.

Features of Model EPT-3060F/EPT-LW1530F

- Electricity is applied momentarily only to control the magnetomotive force when mounting and dismounting workpieces, minimizing heat generated internally to ensure high-precision machining operations.

- Electricity needs not be applied continuously even when holding workpieces, helping reduce running costs.

- The holding power is maintained by the permanent magnet in the event of power failure, improving safety.

- An environment-friendly resin-bonded face plate is employed.

- Type EPT-LW is equipped with a low magnetic force (weak attraction) control function, which is difficult to achieve with conventional permanent electromagnetic chucks, to facilitate stress relieving and workpiece positioning to the same level achieved by electromagnetic chucks. (When the low magnetic force control function is active, the chuck is in the continuous power-on state.) Note that this must be used together with the dedicated Chuck Master (Type EPH-LW)

| [Standard Type]

EPT-3060F |

[Low Magnetic Force Control Type]

EPT-LW1530F |

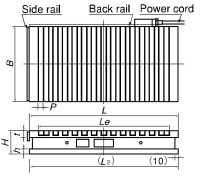

Technical drawings

NOTE: The dimension L2 has not been machined together with the dimension L and some variation exists.

Specification

[Standard Type]

| mm(in) | ||||||||||||||

| Model | Nominal Dimensions |

Top Plate | Pole Pitch | Bottom Plate | Height | Voltage | Current | Power cord |

Mass | Electro Chuck Master |

||||

| B | L | Le | t | P | L2 | h | H | |||||||

| EPT-1530F | 150 (5.90) X 300 (11.8) |

150 (5.90) |

300 (11.8) |

240 (9.44) |

20.5 (0.80) |

14(2+12) 0.55 (0.07+0.47) |

300 (11.8) |

20 (0.78) |

80 (3.14) |

90 VDC |

1.91A | 2m (78.7) |

24kg /52.9lb |

EPS-215B

|

| EPT-1535F | 150 (5.90) X 350 (13.7) |

350 (13.7) |

296 (11.6) |

350 (13.7) |

2.43A | 28kg /61.7lb |

||||||||

| EPT-1545F | 150 (5.90) X 450 (17.7) |

450 (17.7) |

380 (14.9) |

450 (17.7) |

2.64A | 36kg /79.3lb |

||||||||

| EPT-2050F | 200 (7.87) X 500 (19.6) |

200 (7.87) |

500 (19.6) |

436 (17.1) |

500 (19.6) |

5.88A | 3m (118.1) |

53kg /116.8lb |

||||||

| EPT-2060F | 200 (7.87) X 600 (23.6) |

600 (23.6) |

548 (21.5) |

600 (23.6) |

7.87A | 65kg /143.3lb |

||||||||

| EPT-3060F | 300 (11.8) X 600 (23.6) |

300 (11.8) |

529 (20.8) |

25.0 (0.98) |

19.5(2.5+17) 0.79 (0.09+0.66) |

25 (0.98) |

100 (3.93) |

6.14A | 140kg /308.6lb |

|||||

| EPT-4080F | 400 (15.7) X 800 (31.4) |

400 (15.7) |

800 (31.4) |

724 (28.5) |

800 (31.4) |

11.0A | 5m (196.8) |

211kg /465.1lb |

||||||

| EPT-40100F | 400 (15.7) X 1000 (39.3) |

1000 (39.3) |

919 (36.1) |

1000 (39.3) |

12.5A | 265kg /584.2lb |

||||||||

| EPT-5080F | 500 (19.6) X 800 (31.4) |

500 (19.6) |

800 (31.4) |

724 (28.5) |

800 (31.4) |

9.01A | ||||||||

| EPT-50100F | 500 (19.6) X 1000 (39.3) |

1000 (39.3) |

919 (36.1) |

1000 (39.3) |

11.7A | 330kg /727.5lb |

||||||||

*The chuck controller and clamp parts are not included.

*The KANETEC chucks work best when a KANETEC chuck controller is used.

*Turning the parmanent electromagnetic chucks on and off must be limited to once per several minutes.

If on/off operations are repeated frequently, the chucks may be damaged by overheating

[Low Magnetic Force Control Type]

| mm(in) | ||||||||||||||

| Model | Nominal Dimensions |

Top Plate | Pole Pitch | Bottom Plate | Height | Voltage | Current | Power cord |

Mass | Electro Chuck Master | ||||

| B | L | Le | t | P | L2 | h | H | |||||||

| EPT-LW1530F | 150 (5.90) X 300 (11.8) |

150 (5.90) |

300 (11.8) |

240 (9.44) |

20.5 (0.80) |

14(2+12) 0.55 (0.07+0.47) |

300 (11.8) |

20 (0.78) |

80 (3.14) |

180 VDC |

0.80A | 2m (78.7) |

24kg /52.9lb |

EPH-LW205B

EPH-LWE205B |

| EPT-LW1535F | 150 (5.90) X 350 (13.7) |

350 (13.7) |

296 (11.6) |

350 (13.7) |

0.93A | 28kg /61.7lb |

||||||||

| EPT-LW1545F | 150 (5.90) X 450 (17.7) |

450 (17.7) |

380 (14.9) |

450 (17.7) |

1.17A | 36kg /79.3lb |

||||||||

| EPT-LW2050F | 200 (7.87) X 500 (19.6) |

200 (7.87) |

500 (19.6) |

436(17.1) | 500 (19.6) |

3.31A | 3m (118.1) |

53kg /116.8lb |

||||||

| EPT-LW2060F | 200 (7.87) X 600 (23.6) |

600 (23.6) |

548 (21.5) |

600 (23.6) |

3.82A | 65kg /143.3lb |

||||||||

| EPT-LW3060F | 300 (11.8) X 600 (23.6) |

300 (11.8) |

529 (20.8) |

25.0 (0.98) |

19.5(2.5+17) 0.79 (0.09+0.66) |

100 (3.93) |

2.55A | 140kg /308.6lb |

||||||

| EPT-LW4080F | 400 (15.7) X 800 (31.4) |

400 (15.7) |

800 (31.4) |

724 (28.5) |

800 (31.4) |

6.59A | 5m (196.8) |

211kg /465.1lb |

EPH-LWE210B | |||||

| EPT-LW40100F | 400 (15.7) X 1000 (39.3) |

1000 (39.3) |

919 (36.1) |

1000 (39.3) |

6.45A | 265kg /584.2lb |

||||||||

| EPT-LW5080F | 500 (19.6) X 800 (31.4) |

500 (19.6) |

800 (31.4) |

724 (28.5) |

800 (31.4) |

5.41A | ||||||||

| EPT- LW50100F |

500 (19.6) X 1000 (39.3) |

1000 (39.3) |

919 (36.1) |

1000 (39.3) |

6.00A | 330kg /727.5lb |

||||||||

*The chuck controller and clamp parts are not included.

*The KANETEC chucks work best when a KANETEC chuck controller is used.

*Turning the parmanent electromagnetic chucks on and off must be limited to once per several minutes.

If on/off operations are repeated frequently, the chucks may be damaged by overheat.

Kouei is Distributor/Agent of Kanetec.

Other items of Kanetec

Request the quotation for Kanetec

Related Products

-

Hammer Caster 920 SMA / 915 SMA 100-150mm Caster

-

Hachiken EA Expansion

-

Niigata Seiki DL-D5 Transmitter/ Display Set

-

Kyowa ASPD-A-45 ASPD-A Piezoelectric Acceleration Transducer (Built-in Amplifier)

-

Obishi Keiki Seisakusho Straight Edge with Graduation B Type ( Production Example )

-

Kyowa PGR-100KA PGR-A High-pressure-resistant Pressure Transducer