Japan, Kimoto Rubber Industry Co.

Kimoto Rubber Sponge Sheet

Product Made in Japan

Manufacturer: Kimoto

Model: Rubber Sponge Sheet

Features

It is a sheet made by kneading foam material into the raw material rubber. Rubber sponges have two types of bubbles: closed bubbles with independent bubbles and semi-continuous bubbles with semi-continuous bubbles. In addition, there are various materials and hardness like rubber sheets, so you can choose according to your application.

Closed-cell rubber sponge

Each bubble is a closed-cell synthetic rubber sponge covered with a rubber film. It is resilient and has good thermal insulation.

Depending on the type of rubber, it has properties such as flame retardancy (CR) and chemical resistance (EPDM). There are also product variants such as sulphur-free and ultra-low sulfur (EPDM).

| material |

|

|---|---|

| feature |

|

| use |

|

Sulfur-free, ultra-low-sulfur, low-sulfur rubber sponge

(Closed-cell rubber sponge)

Rubber sponges usually use “sulfur” as a method of cross-linking rubber, but some EPDM rubber sponges are cross-linked with “peroxide”. We also handle foams with a low sulfur content.

Low sulfur component = less likely to corrode metals (copper, iron, aluminum, etc.)!

Copper Plate Corrosion Test

Test Condition

1. Specimens… EP-101 (ultra-low sulfur), OP-130 (sulfur vulcanized)

2. Test Method… Corrosion and stickiness test on copper plate

(JIS B 2403:1995 compliant)

Copper plate after the test

* The scratches are made by polishing the copper plate, and other copper plates have similar scratches.

EP-101 (ultra-low sulfur) No

EP-101 (ultra-low sulfur) Nodiscoloration can be confirmed.

There is no stickiness.

OP-130 (sulfur vulcanized) has

OP-130 (sulfur vulcanized) hasa slight black discoloration overall.

There is no stickiness.

| Specimen name and color | notation | Sulfur Analysis Results | Lower limit of quantitation |

|---|---|---|---|

| EP-071 White | Sulfur-free | Less than 0.01% | 0.01% |

| EP-151 White | Sulfur-free | Less than 0.01% | 0.01% |

| EP-100/Black | Ultra-low sulfur | Total sulfur content : 190 mg/kg | 50㎎/kg |

| 0.01% | 0.01% | ||

| EP-101 Gray | Ultra-low sulfur | Less than 0.01% | 0.01% |

| EP-200 Black | Ultra-low sulfur | Total sulfur content : 140 mg/kg | 50㎎/kg |

| 0.01% | 0.01% | ||

| EP-130 Black | Ultra-low sulfur | Total sulfur content : 640 mg/kg | 50㎎/kg |

| EP-070 Black | Low sulfur | 250ppm | 50ppm |

| EP-200NN Black | Ultra-low sulfur | 140ppm | 50ppm |

| Sulfur-free | If no sulfur inclusions are used and not detected in the measurement. |

|---|---|

| Ultra-low sulfur | Like sulfur-free, it does not use sulfur-containing substances, and if black carbon is used, although it has not been detected in measurements. or if a value of less than 0.02% (200 ppm) is detected. |

| Low sulfur | When sulfur powder is not used and a value of 0.02% (200 ppm) or more and less than 0.3% (3,000 ppm) is detected. |

Semi-continuous cellular rubber sponge

It is a foam made of synthetic rubber as a base material and made into a semi-continuous bubble state. It is highly flexible and can be compressed with a slight force. It fits smoothly on uneven areas. EPDM-based, NBR/PVC-based, which is resistant to acid and alkali, and has excellent heat resistance and oil resistance. There are product variations such as acrylic rubber that is low sulfur and does not emit white Mr./Ms..

| material |

|

|---|---|

| feature |

|

| use | It is used as a joint material and sealing material in civil engineering and construction, electrical equipment, automobiles, etc. In addition, it is also used as crevice tape and anti-slip. |

About the processing of rubber sponges

From the above sponges, it is possible to cut and drill to the specified size, apply double-sided tape, and manufacture packing and cushioning materials. We support the selection of materials according to the application and quantity, the proposal of processing methods, manufacturing, and products. Please feel free to contact us.

* Depending on the material, a lot may be required.

Related Products

-

Kokosha Roller Screen

-

NAGANO KEIKI JB50 Pressure Gauge with Reed Switch Contact

-

Nippon Chemical Screw PA6/HR-R(D-L) PA6/Hit rivet (resin nail type)

-

YOSHITAKE GD-6N Pressure Reducing Valve-Steam

-

Vessel No.GT-S4TG Air Screwdriver Torque Control Type

-

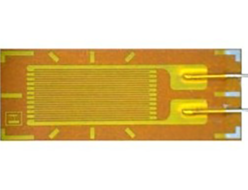

Showa Measuring Instruments N22-FA Series Strain Gages Accessories