Japan, KITZ

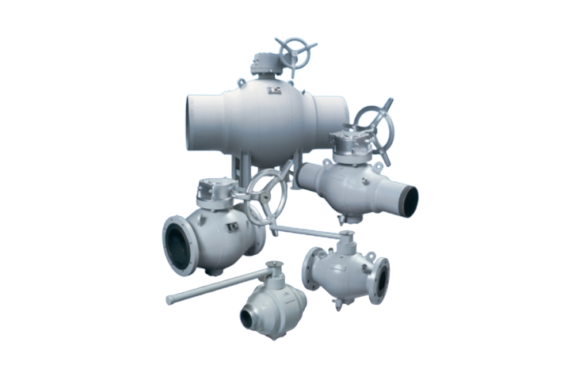

Kitz All-Welded Forged Steel Ball Valve

Product made in Japan

Manufacturer: Kitz

Features

Construction

Body

The forged steel body, which has no longitudinal welds and provides superior material strength, and the body cap are welded on both sides of the stem.

Seat seal

The spring force of the rubber seat compresses the primary seal, pressing the ball into the outer ring. Additionally, force generated by the fluid pressure is utilized, compressing the secondary seal and pressing the seat retainer into the ball, thus applying a “double seal”. Furthermore, a wiper is included inside the seat assembly to prevent the entry of foreign substances and uniformly distribute sealant.

Stem seal

The trough hole and matching face together form a double seal. The bottom stem assembly forms an additional double seal.

Static-electricity prevention mechanism

This mechanism prevents the transmission of static electricity from the ball’s continuous contact with the valve’s outer ring, seat retainer, spring or body.

Fire safe construction

The seat seal assembly often touches the metal of the ball or outer ring, creating the potential for fire. Fire safe construction maintains a seal even when the seat is destroyed by a conflagration. Even if the seat retainer’s O-ring is destroyed, the outer ring’s noncombustible retainer ring will prevent excessive leakage.

*Kitz offers the option of adding noncombustible gaskets to the stem and bottom stem assemblies.

Block and bleed

When a valve is closed, pressure in the body cavity can be expelled into the atmosphere. In such an event, a hose can be attached to a vent valve, allowing the media to be expelled into a safe location. The valve is equipped with a safety lock to prevent the vent valve from blowing off.