Japan, Krohne

Krohne OPTIBAR P 2010 Pressure Level Transmitters

Made in Japan

Manufacturer: KROHNE Japan KK

Model: OPTIBAR P 2010

Features

- Fully welded hygienic design with surface roughness of Ra <0.4 μm

- Suitable for SIP (Sterilisation In Place) and CIP (Cleaning In Place)

- 3A certified process connections

- Extraordinary accuracy of ±0.25%

- Outstanding temperature stability

- Long-term stability: ±0.1%/year (uncertainty)

- Modular design: free combination of device options such as electrical connections, diaphragm material, fill oil, measuring range, process connections

- Ingress protection up to IP68 / NEMA 6P

- ATEX/IECEx intrinsically safe approval for Zone 0

Typical Applications

General

- Absolute and gauge pressure measurement, without crevices and cavities, in gases and liquids

- Hygienic level measurement of liquids

Food, beverage and pharmaceutical industries

- Viscous and crystallizing media

- General sterile process technology

Water industry

- Level measurement in drinking water tanks

Specifications

| General Information | |

|---|---|

| Product type | Pressure transmitter |

| Product family name | OPTIBAR |

| Product positioning | For hygienic pressure and level applications |

| Measurement principle | Hydrostatic |

| Measured media | Liquids, Gases |

| Measuring point | Open tank |

| Operating conditions | |

| Process pressure | max. 40 bar / 580 psi |

| Process temperature | -40…+150°C / -40…+302°F |

| Materials | |

| Diaphragm | Austenitic stainless steel (1.4435/316L) |

| Fill fluid | Silicone oil, Food grade oils (FDA listed) |

| Measuring cell seal | Fluoroelastomer rubber (FKM), Perfluoroelastomer rubber (FFKM) |

| Process connections | |

| Thread connections | Male: Hygienic G½, G1 for hygienic adapters, G½, G¾, G1 (DIN 3852) |

| Hygienic adapters | Clamp (DIN 32676): DN25, DN32, DN40, DN50 Clamp (ISO 2852): 25, 38, 51 Tri-Clamp: ½”, ¾”, 1″, 2″ Collar ferrule (DIN 11851): DN25, DN40, DN50 VARIVENT® N |

| Approvals/Standards | |

| Certificates/Approvals Ex | ATEX, IECEx |

| Certificates/Approvals Hygienic | FDA, 3A, EC 1935/2004 |

| Certificates/Approvals Others | Pressure Equipment Directive (PED) |

| Communication | |

| Analogue outputs | 0…10 VDC, 4…20 mA |

Related Products

-

LOBTEX WP-H (G・R・B・Y・V・S)Water Pump Pliers Skeleton

-

Sawada ALK-50A type (lining) Level gauge – Magnetic Float Type Level Gauge

-

Organo PH-A Polypropylene Housing

-

SAKUSAKU EHB421130 Square End Mill 4-Flute

-

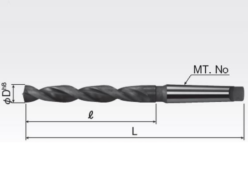

Okazaki Seiko TTD Taper Shank Drills For Iron Frames (Standard Type)

-

Kyowa CR-20 runout fastener Sensor/Transmitter Accessories