Japan, Krohne

Krohne OPTITEMP TCA-P62 Thermocouple Temperature Assemblies

Made in Japan

Manufacturer: KROHNE Japan KK

Model: OPTITEMP TCA-P62

Features

- High temperature measurement of gases

- Thermowell material: 1.4762 / AISI 446 or 1.4767 / Kanthal AF

- Standard or customised lengths

- Different connection heads available (IP54…IP68)

- With optional temperature transmitter

Typical Applications

- High temperature measurement of flue gases or other furnace exhaust gases at ambient or low operating pressures

- Suitable for combustion process applications in various industries:

- Power generation

- Iron and steel

- Chemical

- Rubbish incineration

- Basic materials

Specifications

| General Information | |

|---|---|

| Product type | Temperature assembly |

| Product family name | OPTITEMP |

| Product positioning | For high temperature applications |

| Product variants | Standard: OPTITEMP TCA-P62 |

| Measurement variables | Temperature |

| Measurement principle | Thermocouple (TC) |

| Measured media | Gases |

| Assembly with thermowell | Yes |

| Temperature assembly design | DIN-style |

| Thermowell type | Multipart welded |

| Thermowell form (according to DIN 43772) | Form 1 |

| Sensor mounting | Plug-in |

| Measuring insert replaceable | Yes |

| Measuring insert type | Replaceable spring loaded mineral isolated measuring insert OPTITEMP TC 100 |

| Tolerance class (according to DIN EN 60584) | 1 |

| Temperature sensor connection type option | Ceramic terminal block, Flying wires, Temperature transmitter |

| Thermocouple (TC) configuration | 1 x Type J, 1 x Type K, 2 x Type J, 2 x Type K |

| Thermowell diameters | Ø19 mm / 0.75″, Ø22 mm / 0.87 |

| Thermowell tip design | Straight |

| Mounting point | Pipe |

| Measuring point | Pipe |

| Operating Conditions | |

| Process temperature | -40…+1150°C / -40…+2100°F |

| Materials | |

| Wetted parts | Ferritic stainless steel (1.4762/AISI 446), Ferritic alloy (1.4767/Kanthal AF) |

| Process Connections | |

| Compression fittings | Male: G3/4, G1 |

| Approvals/Standards | |

| Certificates/Approvals Ex | ATEX, IECEx |

Related Products

-

BBK Technologies 410-FMK Manifold Kit (With Hoses) In A Carring Case

-

Saitama Seiki U-TOOL U-71 Tip Sander

-

Kyowa PVL-20KA PVL Voltage-output Pressure Transducer

-

TAIYO SA-40 Series Shock Absorber (Fixed Type (Air Return Type))

-

TONE CSC2000 Service Board Carry

-

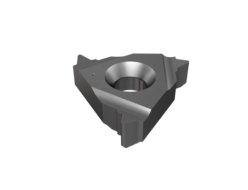

SAKUSAKU 16IR 19W Outer Thread Cutting Insert Whitworth 55°