Japan, Krohne

Krohne OPTITEMP TRA-S50 Resistance Temperature Assemblies

Made in Japan

Manufacturer: KROHNE Japan KK

Model: OPTITEMP TRA-S50

Features

- Temperature measurement of liquids, gases and steam

- Modular design: Flexible union neck tube or threaded DIN neck tube for easy exchange under operating conditions

- Without thermowell, sheath material: 1.4404 / 316L

- Also suitable for installation into existing thermowells

- Standard or customised lengths

- Different connection heads available (IP54…IP68)

- With optional temperature transmitter

- Available as intrinsically safe: ATEX, IECEx

Typical Applications

- For installation into existing thermowells as well as bearings or similar machinery in various industries:

- Chemical and petrochemical

- Oil and gas

- Power generation

- Machinery and apparatus / OEM

- Iron and steel

- Pulp and paper

Specifications

| General Information | |

|---|---|

| Product type | Temperature assembly |

| Product family name | OPTITEMP |

| Product positioning | For use in existing thermowells or machinery |

| Product variants | Standard: OPTITEMP TRA-S50 EX: OPTITEMP TRA-S50 Ex |

| Measurement variables | Temperature |

| Measurement principle | Resistance (RTD) |

| Measured media | Liquids, Gases, Steam |

| Assembly with thermowell | No |

| Temperature assembly design | ASME-style |

| Sensor mounting | Screw-in |

| Measuring insert replaceable | Yes |

| Measuring insert type | Replaceable spring loaded mineral isolated measuring insert OPTITEMP TR 100 |

| RTD element type | 1 x Pt100, 2 x Pt100 |

| RTD configuration | 3-wire, 4-wire |

| Tolerance class (according to DIN EN 60751) | 1/10 DIN B, A, AA, B |

| Temperature sensor connection type option | Ceramic terminal block, Flying wires, Temperature transmitter |

| Sheath diameters | Ø6 mm / 0.23″ |

| Mounting point | Pipe, Machinery |

| Measuring point | Machinery, Pipe |

| Operating Conditions | |

| Process temperature | -200…600°C / -328…1100°F |

| Materials | |

| Wetted parts | Austenitic stainless steel (1.4404/316L) |

| Process Connections | |

| Thread connections | Male: G½ M 18 x 1.5 mm ½ NPT |

| Approvals/Standards | |

| Certificates/Approvals Ex | ATEX, IECEx |

Related Products

-

Chiyoda Seiki CA-4-D1S Alarm Panel/remote Monitoring System Compact Alarm Box (Desktop Type) Share

-

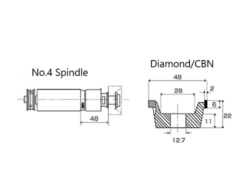

UHT Corporation #100 Diamond Grinding Wheels For Spindle No.4

-

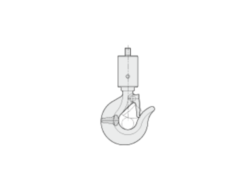

Kyowa THD-10 hook Sensor/Transmitter Accessories

-

Nippon Daiya Valve Lining Diaphragm Valves With Excellent Corrosion And Chemical Resistance

-

TOKU MG-7204B Grinders

-

Krohne OPTIFLUX 6100 Electromagnetic Flowmeter