Japan, Krohne

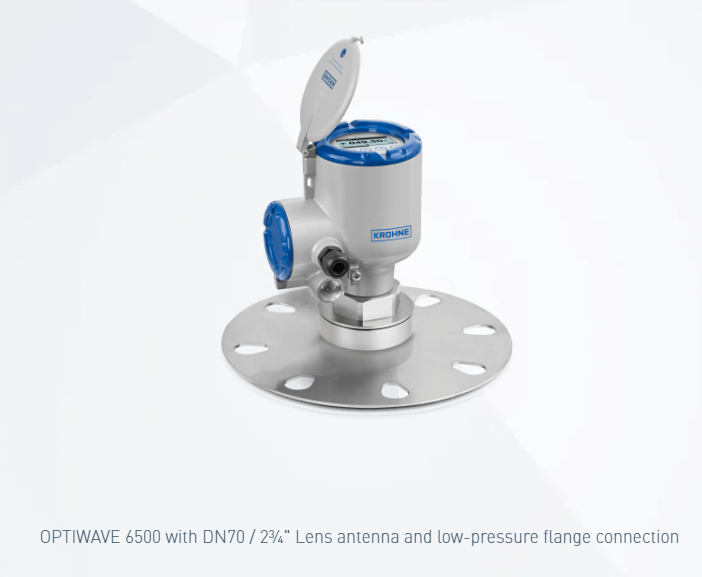

Krohne OPTIWAVE 6500 Radar (FMCW) Level Transmitter

Made in Japan

Manufacturer: KROHNE Japan KK

Model: OPTIWAVE 6500

Features

- 2-wire, loop-powered, with HART®7

- High dynamics for clear vision despite dusty atmospheres or low reflective media

- Empty tank spectrum function eliminates false reflections caused by tank internals

- Flush-mounted PEEK or PTFE Lens antennas (no tank intrusion):

- DN70 / 2¾″ with 4° beam angle for distances up to 100 m / 328 ft

- 112 mm / 4.4″ antenna extension for long nozzles

- Unaffected by angle of repose

- Purging system for antenna cleaning

- TBM (Tank Bottom Management) ensures reliable measurement even in empty tanks:

- dedicated algorithms to filter and compensate for irregular radar wave reflections that occur at tank bottom when the vessel is empty

- allows for quick and easy commissioning of tanks regardless of their size, material or geometry

- ±2 mm / ±0.08″ accuracy

- Large choice of flange and thread connections

- Low-cost 316L low-pressure flange discs

- Large, backlit LCD screen with 4-button keypad for operation with bar magnet; no need to open the housing cover

- PACTware™, HART® DD and DTM provided free of charge with full functionality

- Extensive device diagnostics acc. to NAMUR NE 107

- SIL 2/3 certified for safety-related applications

- 3-year warranty

Typical Applications

Level measurement in high and narrow silos with internal obstructions, buffer silos, bulk storage containers, hoppers

Processes with fast changing levels (≤60 m/min / 196.85 ft/min)

Specifications

| General Information | |

|---|---|

| Product type | Level transmitter |

| Product family name | OPTIWAVE |

| Product positioning | For powders and dusty atmospheres |

| Measurement variables | Distance, Level, Mass, Reflection, Volume |

| Measurement principle | Radar |

| Level measurement type | Continuous measurement |

| Contact to measured medium | No |

| Interface measurement | No |

| Redundancy | No |

| Measured media | Solids, Granulates, Powders |

| Measuring range (solids) | 0…100 m / 0…328 ft |

| Ambient temperature | -40…+80°C / -40…+176°F |

| Measuring point | Silo, Stockpile, Conveyor belt, Shaft, Bunker, Crusher |

| Operating conditions | |

| Process pressure | -1…40 barg / -14.5…580 psig |

| Process temperature | -50…+150°C / -58…+302°F |

| Materials | |

| Antenna | Polyetheretherketone (PEEK) |

| Gaskets | Ethylene propylene diene monomer (EPDM), Fluoroelastomer rubber (FKM/FPM), Kalrez® 6375 |

| Process connections | |

| Flange connections | EN (1092-1): DN50…200 ASME (B 16.5): 2…8″ JIS (B 2220): 50…200A |

| Pressure ratings | EN (1092-1): PN40 ASME (B 16.5): Cl 300# JIS (B 2220): 10k |

| Thread connections | Male: G1½, G3 1½ NPT, 3 NPT |

| Approvals/Standards | |

| Ingress protection | IP66/68, NEMA4X/6P |

| Certificates/Approvals Ex | ATEX, cQPSus, IECEx, NEPSI, EAC Ex, KCs |

| Certificates/Approvals Marine | DNV |

| Certificates/Approvals Others | WHG, CRN / ASME B31.3 |

| Certificates/Approvals Safety | SIL 2/3 |

| NAMUR compliance | NE 107, NE 21, NE 43, NE 53 |

| Communication | |

| Analogue outputs | 4…20 mA |

| Digital outputs | FOUNDATION™ fieldbus, HART®, Profibus-PA |

| Accuracy | |

| Accuracy (solids) | ±2 mm / ±0.08 in |