Kurimoto

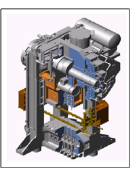

Kurimoto C2F-25 Forging Press

Product Made in Japan

Manufacturer: KURIMOTO

Model: C2F-25

Accommodate the Specifications in accordance with Customers’ needs for Optimum Operation

C2F Series perform stable operation and a varieties of Options can be added to suit for your needs and requirement.

High rigid frame structure achieves very precise and constant forging operation.

Features

High-Rigidity and High-Precision Structure

Upper Frame, Upright, and Lower Frame are tightened by Four Tie Rods to be very Rigid Frame Structure.

Wide Range of Allowable Eccentric Load

Adoption of 2 Point Connecting Rods allows very wide Allowable Eccentric Load which contributes Forged Parts Accuracy Improvement.

KURIMOTO’s Patented Slide Adjustment / Stick Release Device

Simple and Reliable Structure with Simple Operation

Automatic Slide Adjustment Device – Achieve High Precision

Combination of Hydraulic Cylinder and Eccentric Wrist Pin enable adequate die height adjustment during high speed operation to resolve the Forged Parts Accuracy Issue.

Easy Maintenance

Press Main keeps clean with Oil Lubrication. It is circulated type which allows collection / re-use. Hard Plate is being used on Slide Gib for KURIMOTO Press to maintain long preciseness. For Clutch and Brake, Block type Friction Material is being use for ease use and longevity.

Applications

Hot / Warm Forged Parts

Non-ferrous (Aluminum) Forged Parts

Options

Optional accessories to Press

Load meter with over load sensor

Thermometer for journals & con-rods with alarm

Adaptor plate

Bolster plate

Peripheral Devices

Other options and various kind of peripheral devices are available.

Automatic Transfer System

The simplified structure contributes to better maintainability.

The ball screw ensures high-accuracy and high-speed transfer with back-lash less.

The servo control provides the optimum transfer motion for particular product and simplify setting and selection of the die lubrication pattern.

Left/Right and Front/Rear boxes are independently positioned.

Layout flexibility around loading and unloading is greatly improved.

Material Supply System

Can be customed to accommodate specific product, transfer speed and applications.

Can be designed to incorporate an optional servo system.

Accommodates optional design variations such as vertical-horizontal combination transfer.

Die Lubrication System

The timing of servo-driven movable nozzle is synchronized with the automatic transfer system.

This ensure the most efficient due lubrication, thus extending die service life.

Quick Die Changer (QDC) System

We offer a variety of systems including T-type,V-type, I-type and F-type to accommodate diverse facility layouts.

Specification

| C2F-16 | C2F-20 | C2F-25 | C2F-30 | C2F-40G | C2F-50 | C2F-63 | |

| Capacity (MN) | 16 | 20 | 25 | 30 | 40 | 50 | 63 |

| Die height (㎜) | 900 | 950 | 1050 | 1100 | 1100 | 1370 | 916 |

| Stroke length (㎜) | 320 | 320 | 320 | 360 | 400 | 400 | 450 |

| Stroke rate (rpm) | 60 | 60 | 60 | 50 | 45 | 45 | 45 |

| Slide adjustmen (㎜) | 10 | 10 | 10 | 10 | 10 | 10 | 10 |

| Adapter size (㎜×㎜) |

1030 ×1100 |

1200 ×1200 |

1200 ×1300 |

1200 ×1300 |

1600 ×1400 |

1720 ×1600 |

1860 ×1700 |

| Bolster size (㎜×㎜) |

1150 ×1200 |

1350 ×1200 |

1350 ×1300 |

1350 ×1500 |

1800 ×1600 |

1720 ×1600 |

1720 ×1600 |

| Press height (㎜) | 6300 | 6600 | 7200 | 7400 | 9000 | 10100 | 9800 |

Sample Forging Parts: Common Rail