Japan, Kurimoto

Kurimoto Continuous Band Type Through-flow Dryer

Product Made in Japan

Manufacturer: KURIMOTO

This dryer serves to layer materials up to 30 to 100 mm in thickness on the band comprised of wire mesh or perforated sheet and perform drying by feeding hot air from the top or the bottom at right angles to the materials layered.

Features

Evenly dried products are discharged.

This dryer is used to dry formed materials, enabling you to get homogeneous products with uneven drying diminished.

Products of low moisture content are discharged.

Extended contact time makes it possible to dry materials of high internal moisture up to considerably low moisture content.

Minimized material destruction

Materials are dried in a state of packed layer, enabling you to get products with minimized particle destruction.

Short drying time

Compared to concurrent-flow compartment dryers, you are able to finish drying step in far shorter period of time.

Reduced floor space for drying

Materials can be layered thick in a state of packed bed for shorter drying time, reducing the floor space required for drying as well as the volume of the equipment.

Diminished flying of materials

Materials are dried as they are left at rest to diminish their flying, enabling you to cut the costs of flue gas treatment.

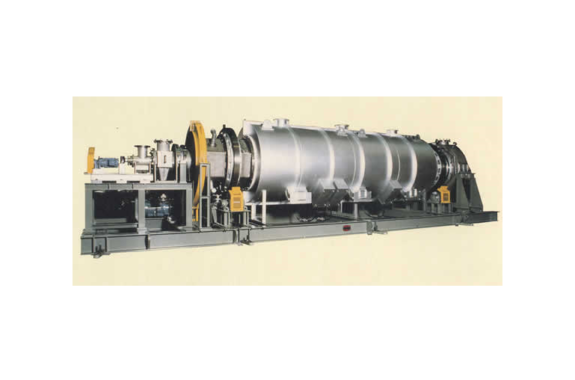

Construction

The above figure shows an example of sludgy materials forming and drying system. Materials formed through the pelletizer are stacked in layers on the conveyor screen to enter the drying chamber, where the materials, while passing to the outlet, are dried with hot air forcibly ventilated from the top through the bottom of the material layers.

Application

Fibrous materials

Solids forming of sludgy materials

Calcium carbonate and magnesium carbonate

Titanium oxide, white carbon, and carbon black

Synthetic resin pellets