Japan, Kurimoto

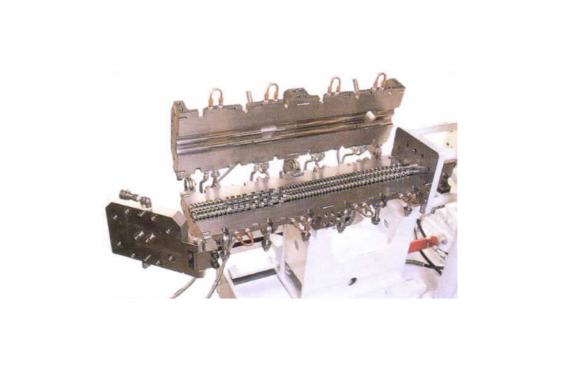

Kurimoto KEXP Powder Paints Dedicated Extruder

Product Made in Japan

Manufacturer: KURIMOTO

The Kurimoto KEXP series extruders are a two-shaft continuous kneading machine specially designed to meet the needs of functions for key steps of thermosetting resin powder paint manufacturing process, such as melting, kneading and dispersing steps, which therefore can be called a processor dedicated for powder paints.

Features

Minimal retention of raw materials inside the barrel enables no production of gelled paint.

Superb self-clearing capability is provided between screws and between the barrel internal surface and screw.

Minimal dead space at the raw material discharging section provides prompt discharging.

Precise temperature control of processing materials

The cooling jacket of the barrel has a structure enabling efficient cooling (heating).

The shaft cooling can be performed from the screw side.

Great ease of cleaning inside the barrel for changing the type and color of materials

The barrel is two-segmented into upper and lower parts. The upper part can be opened and closed easily by a hydraulic cylinder.

Wear resistant structure

Standard barrels have a liner structure of Kurimoto’s special wear-resistant steel (CHST).

The liner is two-segmented into for upper and lower parts and further 4-segmented in the shaft direction, enabling you to replace only wear parts.

Promising increased processing capacity

Ability to support high-torque operation is provided.

Vertical forced feed unit is equipped with the raw material hopper.

Applications

Powder paints

Toner

EMC

Specifications

| Model number | Max. rotation [min-1] |

Motor capacity [kW] |

L/D | Throughput (reference value) [kg/h] |

Dimensions W×L×H[mm] |

Weight [kg] |

|---|---|---|---|---|---|---|

| KEXP 40 |

300 | 11 | 17.5 | 60 | 1000×2500×1800 | 1500 |

| KEXP 50 |

300 | 22 | 17.5 | 120 | 1100×3000×1900 | 2500 |

| KEXP 65 |

300 | 45 | 17.5 | 250 | 1200×3700×2000 | 3500 |

| KEXP 80 |

300 | 90 | 17.5 | 500 | 1500×4400×2200 | 4500 |

| KEXP 100 |

300 | 180 | 17.5 | 1000 | 1900×5200×2400 | 8000 |

| KEXP 125 |

300 | 360 | 17.5 | 1900 | 2300×6200×2600 | 12000 |

Related Products

-

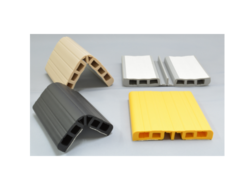

Kimoto Peace of mind guard Corners

-

Chiyoda Seiki MCHP-100A Semi-automatic Switching Gas Supply Device Stand Set (standard flow rate: 50ℓ/min・Air)

-

Super Tool SLH1N/2N/3N Super Lock Hook

-

TONE MDD220T Shear Wrench

-

Kyowa LCW-C-10KN35SA3 LCW-C-SA3 Washer-type Load Cell

-

Chiyoda Seiki GS-500 Series Large Flow Self-powered Pressure Regulator (Primary pressure: 15.0 MPa or less/adjustment pressure 0.2 to 1.5 MPa, standard flow rate: 560 m3/h・Air)