Kuwana Metals 03W Series Chilled Tower

Manufacturer: Kuwana Metals, Ltd.

Model : 03W Series

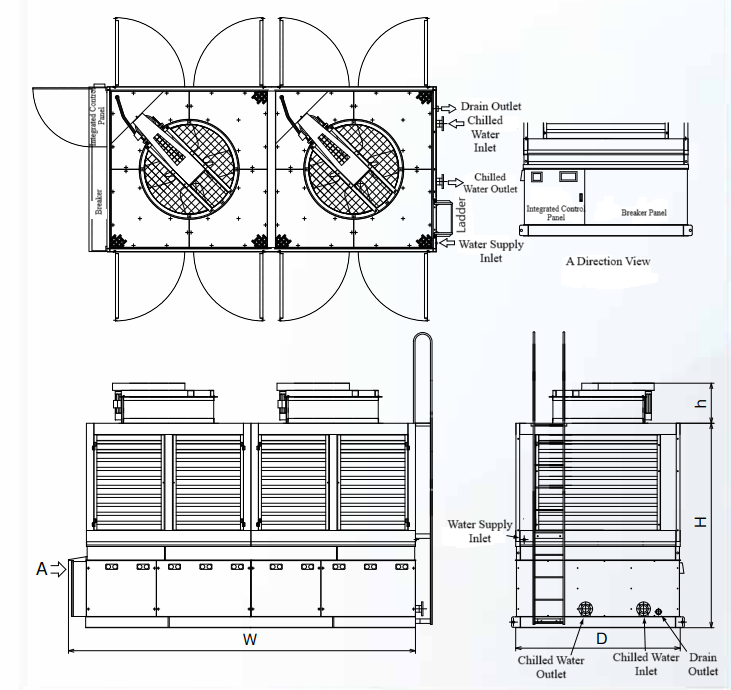

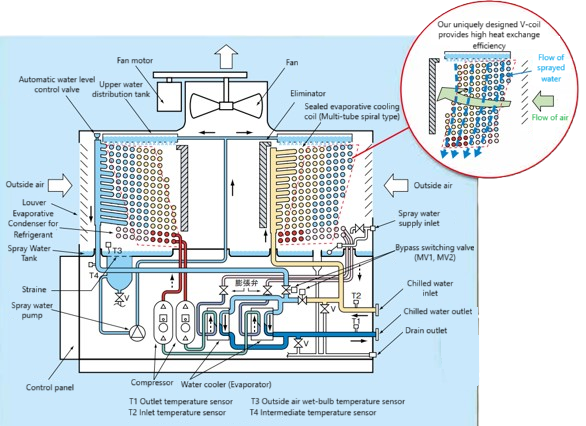

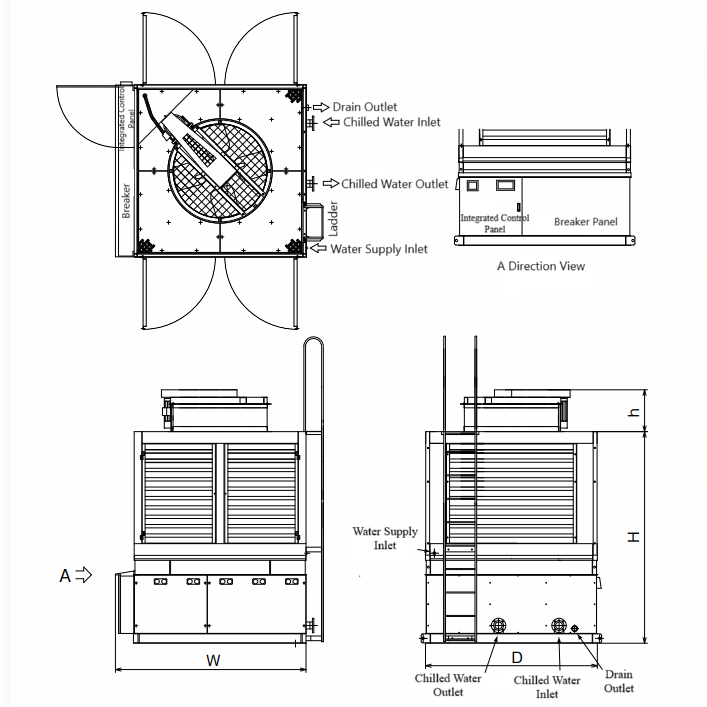

Structural Diagram

Specification

| Item (Unit) | Model | ||||||

|---|---|---|---|---|---|---|---|

| CTS-303W | CTS-403W | CTS-503W | CTS-603W | CTS-803W | CTS-1003W | ||

| Performance ※1 | Inlet temperature 20°C (Cooling capacity ) (kW) Outlet temperature 15°C (Chilled water flow rate) (m³/h) | 102.3/120.3 | 136.6/160.5 | 170.9/200.6 | 205.2/240.7 | 273.3/320.9 | 341.9/401.2 |

| 17.6/20.7 | 23.5/27.6 | 29.4/34.5 | 35.3/41.4 | 47.0/55.2 | 58.8/69.0 | ||

| Inlet temperature 25°C (Cooling capacity ) (kW) Outlet temperature 20°C (Chilled water flow rate) (m³/h) | 109.9/133.1 | 146.5/177.3 | 183.1/221.5 | 219.8/265.7 | 293.0/354.7 | 366.3/443.0 | |

| 18.9/22.9 | 25.2/30.5 | 31.5/38.1 | 37.8/45.7 | 50.4/61.0 | 63.0/76.2 | ||

| Inlet temperature 30°C (Cooling capacity ) (kW) Outlet temperature 25°C (Chilled water flow rate) (m³/h) | 118.0/145.3 | 157.6/194.2 | 197.1/242.4 | 236.6/290.7 | 315.1/387.8 | 394.2/484.9 | |

| 20.3/25.0 | 27.1/33.4 | 33.9/41.7 | 40.7/50.0 | 54.2/66.7 | 67.8/83.4 | ||

| Chilled water flow rate range (Minimum – Maximum) (m³/h) | 9~27 | 12~36 | 15~45 | 18~54 | 24~72 | 30~90 | |

| Internal pressure loss (flow rate) (kPa at m³/h) | 158(18) | 158(24) | 158(30) | 158(36) | 158(48) | 158(60) | |

| Rated Freezing Capacity (50/60Hz) (Ton) | 158(18) | 158(24) | 158(30) | 158(36) | 158(48) | 158(60) | |

| High-Pressure Gas Safety Law Classification ※3 | 50Hz | Manufacturing Notification Not Required | Manufacturing Notification Not Required / Manufacturing Notification Required | Manufacturing Notification Required | |||

| 60Hz | |||||||

| Exterior | Main Frame, Fan, Ladder: Hot-Dip Galvanized, Mechanical Room Decorative Panel: Highly Corrosion-Resistant Hot-Dip Galvanized Steel Plate, Louver: Aluminum | ||||||

| External Dimensions | Width [W](mm) | 2,200 + 240 (Control Panel Roof) | 4,400 + 240 (Control Panel Roof) | ||||

| Depth [D] (mm) | 2,200 | ||||||

| Height to Shoulder [H] (mm) | 2,178 | 2,444 | 2,712 | 2,203 | 2,469 | 2,737 | |

| Fan Height [h] (mm) | 536 | ||||||

| External Diagram | A | B | |||||

| Fan | Model | Axial Fan (V-Belt Drive Type) | |||||

| Dimensions : mm | φ1,200 | ||||||

| Motor Output : kW (Number of Poles) × Number of Units | 3.7 (6) ×1 | 5.5 (6) ×1 | 3.7 (6) ×2 | 5.5 (6) ×2 | |||

| Spray Pump | Model Type | Stainless steel centrifugal pump | |||||

| Motor Output : kW (Number of Poles) × Number of Units | 0.75 (2) ×1 | 0.75 (2) ×2 | |||||

| Compressor | Model Type | Fully Enclosed Scroll Type | |||||

| Motor Output : kW (Number of Poles) × Number of Units | 7.5 (2) ×3 | 7.5 (2) ×4 | 7.5 (2) ×5 | 7.5 (2) ×6 | 7.5 (2) ×8 | 7.5 (2) ×10 | |

| Refrigerant Control System | External Equalizing Type Automatic Expansion Valve | ||||||

| Protection Device | High-Pressure Cutout Device, Low-Pressure Cutout Device, Discharge Gas Overheat Prevention Temperature Switch, Breaker (NFB), Thermal Relay, Reverse Rotation Prevention Relay, Anti-Freezing Flow Switch, Anti-Freezing Temperature Switch | ||||||

| Refrigerant Type | R407C | ||||||

| Chilled Water System Operating Pressure (Normal Use) (MPa) | 0.7 | ||||||

| Spray Water Replenishment Amount ※4 (m³/h) | 0.31/0.36 | 0.41/0.48 | 0.51/0.68 | 0.64/0.73 | 0.83/0.96 | 1.03/1.19 | |

| Electrical Characteristics ※5 | Power Consumption(kW) | 29/35 | 37/45 | 46/56 | 57/70 | 73/90 | 91/112 |

| Operating Current(A) | 112/115 | 142/147 | 173/179 | 222/228 | 282/291 | 344/356 | |

| Power Supply | Driving Power Supply | AC3ϕ 200V 50/60Hz | |||||

| Control Power Supply | AC1ϕ 200V 50/60Hz | ||||||

| Piping Dimensions | Chilled Water Inlet/Outlet | JIS 10K Flange 80A | JIS 10K Flange 100A | ||||

| Spray Water Supply Inlet | Rc 3/4 | ||||||

| Drain Connection Port | Rc 2 | ||||||

| Product Mass (Operating Mass) (kg) | 2,500(3,210) | 2,900(3,730 | 3,100(4,050) | 4,700(6,140) | 5,300(7,050) | 5,900(7,910) | |

| Stored Water Volume | Spray System (m³) | 0.34 | 0.35 | 0.36 | 0.68 | 0.71 | 0.73 |

| Circulation System (m³) | 0.37 | 0.48 | 0.59 | 0.76 | 1.04 | 1.28 | |

| Operating Noise (Measured at 2m Distance and 1.5m Height) ※6 | dB(A) | 72 | 73 | 74 | 74 | 75 | 76 |

| Standard Accessories | Ladder, Anti-Vibration Pad, Circulating Water Strainer | ||||||

| Options ※7 | Safety Fence, Ladder Backrest, Automatic Blowdown Management Device (Conductivity Management Device), Spray System & Chilled Water System Anti-Freezing Heater, Live Electrical Part Cover, Main Power Supply Voltage Variation Support (50Hz-400V / 60Hz-440V), Control Circuit Voltage Variation Support (100V), Salt Damage Resistant Specification, Large Flow Rate Specification, Small Flow Rate Specification, Others. | ||||||

- ※1… Performance (cooling capacity, chilled water flow rate) indicates the values at an ambient wet-bulb temperature of 27°C.

- ※2… Please adhere to the specified chilled water flow range. Insufficient flow may lead to freezing damage or clogging due to dirt accumulation, while excessive flow may cause corrosion due to the impact of flow velocity.

- ※3… In cases where a high-pressure gas manufacturing notification is required under the High-Pressure Gas Safety Act, please submit the necessary documents to the prefectural governor.

- ※4… The spray water replenishment volume indicates the value under the conditions of an ambient wet-bulb temperature of 27°C, a chilled water inlet temperature of 30°C, and a chilled water outlet temperature of 25°C (with a fourfold concentration blowdown).

- ※5… Electrical characteristics (power consumption, operating current) indicate values under conditions of an ambient wet-bulb temperature of 27°C, a chilled water inlet temperature of 30°C, and a chilled water outlet temperature of 25°C. Additionally, the transformer capacity and wiring capacity should be at least 1.2 times the power consumption and operating current to account for variations in usage conditions.

- ※6… The operating noise level represents values measured outdoors in an open area with minimal reflections (A-scale). In actual installation conditions, surrounding reflections may increase the noise level by approximately 3 dB(A).

- ※7… When requesting optional features, specifications should generally be provided at the time of ordering the main unit.

- ※8… These are recommended optional features for enhanced safety and functionality.

External Diagram

Figure A

Note: Please ensure a service space of at least 1.5 meters around the entire unit.

Figure B

Note: Please ensure a service space of at least 1.5 meters around the entire unit.