Kuwana Metals

Kuwana Metals A Series Chilled Tower

Manufacturer: Kuwana Metals, Ltd. (Gourd Brand)

Model : A Series

Features

- Chilled Tower: A Pioneer in Energy Saving.

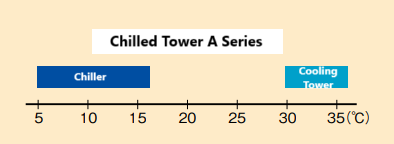

- Provides environmentally friendly chilled water at 10°C to 30°C, available year-round.

Supply Temperature Range

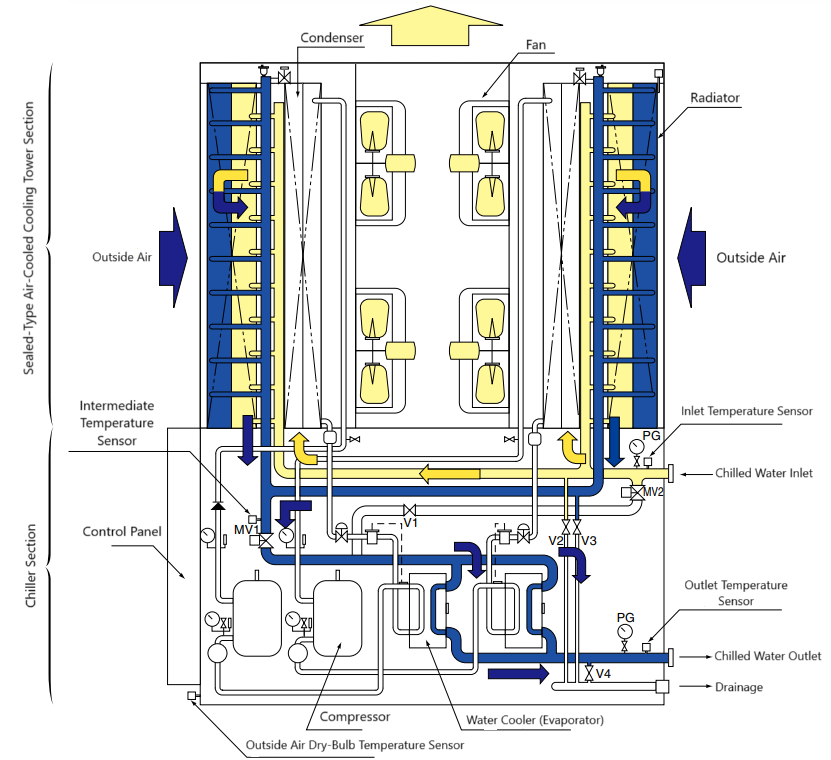

Cooling Mechanism

Operation During Low to Medium Temperature Periods (Winter to Intermediate Seasons)

- During periods of low ambient temperature, the chilled water returning from the load side is sent to the sealed-type air-cooled cooling tower (cooling tower section). Utilizing the outside air drawn in by the fan, the water is cooled to the set temperature.

- By using inverter control for fan speed regulation, the system precisely and stably supplies chilled water at the desired temperature to the load side.

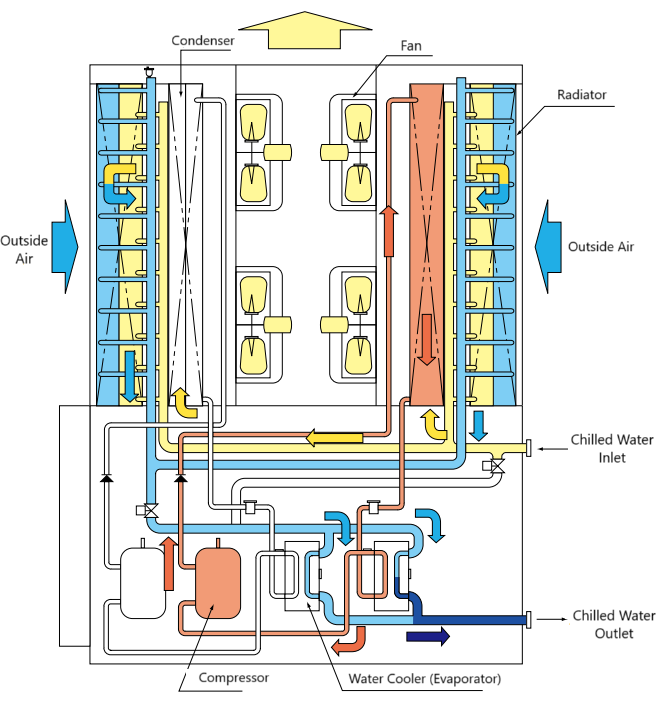

Operation During Medium to High Temperature Periods (Intermediate to Summer Seasons)

- During periods of high ambient temperature, when the cooling tower section alone is insufficient for cooling, the compressors are sequentially operated to cool the water to the set temperature.

- By controlling the number of operating compressors, the system ensures a stable supply of chilled water to the load side.

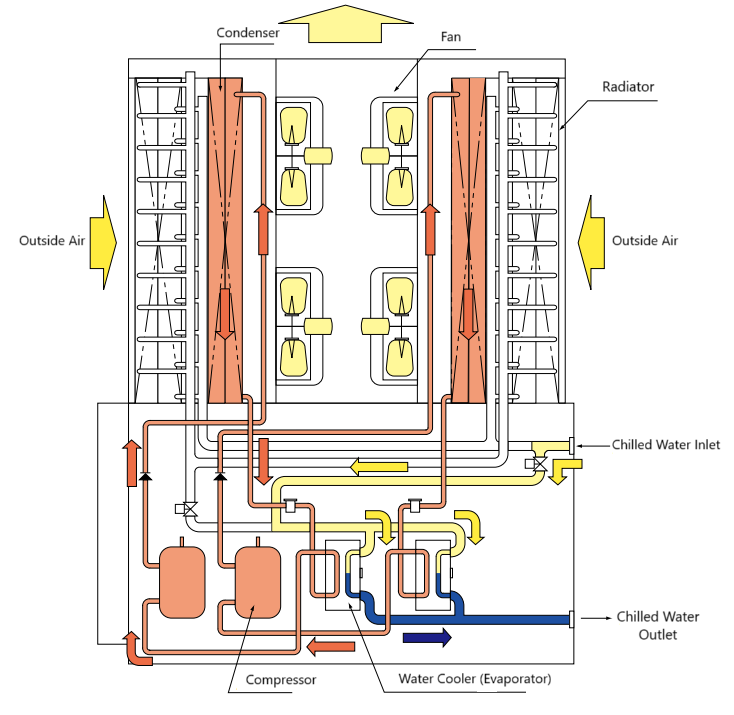

Operation During High-Temperature Peak Periods (Bypass Operation)

- When the outside air dry-bulb temperature becomes higher than the chilled water inlet temperature of the chilled tower, passing water through the cooling tower section would cause heat absorption and cooling loss.

- In this case, the system automatically redirects the water directly to the chiller section (bypass operation) to prevent cooling loss and efficiently supply chilled water at the set temperature.

Specification Table

| Item (Unit) | Model | ||||

|---|---|---|---|---|---|

| CTS-202A2 | CTS-402A2 | CTS-602A2 | CTS-802A2 | ||

| Performance ※1 | Cooling Capacity at Inlet Temperature 25°C (kW) Chilled Water Flow at Outlet Temperature 20°C (m³/h) | 69.8/80.2 | 139.5/160.5 | 209.3/240.7 | 279.1/320.9 |

| 12.0/13.8 | 24.0/27.6 | 36.0/41.4 | 48.0/55.2 | ||

| Cooling Capacity at Inlet Temperature 35°C (kW) Chilled Water Flow at Outlet Temperature 25°C (m³/h) | 77.9/89.5 | 155.8/179.1 | 233.7/268.6 | 311.7/358.1 | |

| 6.7/7.7 | 13.4/15.4 | 20.1/23.1 | 26.8/30.8 | ||

| Chilled Water Flow Range (m³/h) | 6~18 | 12~36 | 18~54 | 24~72 | |

| Internal Pressure Loss (kPa at m³/h) | 56(12) | 56(24) | 56(36) | 56(48) | |

| Legal Refrigeration Capacity (Ton) | 5.78/6.88 | 11.56/13.76 | 17.34/20.64 | 23.12/27.52 | |

| High-Pressure Gas Safety Law Application Category ※3 | No Report Required | No Report Required / Report Required | Report Required | ||

| Exterior | Hot-Dip Galvanized Coating, High Corrosion-Resistant Hot-Dip Galvanized Steel Plate | ||||

| External Dimensions | Width (+Control Panel) (mm) | 2,200(+215) | 2,200(+215) | 4,400(+215) | 4,400(+215) |

| Depth (mm) | 1,100 | 2,200 | 2,200 | 2,200 | |

| Height (mm) | 3,150 | 3,150 | 3,150 | 3,150 | |

| Fan | Model | Axial Fan | |||

| Outer Diameter (mm) | 600 | ||||

| Motor Output (kW (poles) × units) | 0.75(6)×4 | 0.75(6)×8 | 0.75(6)×12 | 0.75(6)×16 | |

| Compressor | Model | Scroll | |||

| Motor Output (kW (poles) × units) | 7.5(2)×2 | 7.5(2)×4 | 7.5(2)×6 | 7.5(2)×8 | |

| Refrigerant Control Device | External Equalization Type Thermal Expansion Valve | ||||

| Protection Device | High-Pressure Cutoff Device, Low-Pressure Cutoff Device, Discharge Gas Overheat Prevention Temperature Switch Breaker (NFB), Freeze Prevention Flow Switch, Freeze Prevention Temperature Switch Thermal Relay (Overload Protection Device), Reverse Rotation Prevention Relay | ||||

| Refrigerant Type | R407C | ||||

| Maximum Operating Pressure for Chilled Water System (MPa) | 0.7 | ||||

| Electrical Characteristics ※4 | Power Consumption (kW) | 21.2/26.2 | 42.2/52.2 | 62.2/78.2 | 83.2/104.2 |

| Operating Current (A) | 71.0/82.0 | 142.0/163.0 | 212.0/244.0 | 283.0/325.0 | |

| Power Supply※5 | AC3φ200V 50/60Hz | ||||

| Piping Dimensions | Chilled Water Inlet/Outlet | 65A JIS10K Flange | 80A JIS10K Flange | 100A JIS10K Flange | |

| Drain Connection Port | Rc1 | ||||

| Product Weight (Operating Weight) (kg) | 1,340(1,400) | 2,280(2,410) | 3,350(3,530) | 4,230(4,490) | |

| Water Capacity (m³) | 0.06 | 0.13 | 0.18 | 0.26 | |

| Accessories | 1 Set of Vibration Isolation Pads, 1 Strainer | ||||

| Noise Level (Measured at 2m Distance and 1.5m Height) ※6 (dB(A)) | 66 | 68 | 70 | 71 | |

- ※1 Performance values (cooling capacity, chilled water flow rate) are based on an ambient dry-bulb temperature of 35°C.

- ※2 Please adhere to the specified chilled water flow range.

- If the flow rate is too low, it may cause freezing damage or blockages due to sediment buildup.

- If the flow rate is too high, it may lead to corrosion due to excessive velocity.

- ※3 Depending on the model, submission of a high-pressure gas manufacturing report may be required under the High-Pressure Gas Safety Act.

- ※4 Electrical characteristics (power consumption, operating current) are based on the following conditions:

- Ambient dry-bulb temperature: 35°C

- Inlet temperature: 35°C

- Outlet temperature: 25°C

- Additionally, to account for usage variations, transformer capacity and wiring capacity should be at least 1.2 times the power consumption and operating current.

- ※5 The control circuit operates at AC 200V 50/60Hz.

- ※6 Noise levels are measured in an environment with minimal surrounding reflections (A-scale).

- In actual installation conditions, noise levels may vary by approximately ±3 dB(A) due to surrounding noise and reflections.

- ◆ The specifications in this document are subject to change without notice.

For inquiries, please contact our sales department to create a delivery specification sheet tailored to your usage conditions.

Option

If you request an option, it must be specified at the time of ordering the main unit as a general rule.

| No. | Option | Description |

|---|---|---|

| ① | Charging Section Cover | To ensure electric shock safety, a transparent acrylic cover is installed on the exposed charging section. |

| ② | Main Power Supply Voltage Compatibility | Compatible with AC 3-phase 400V 50Hz and 440V 60Hz. |

| ③ | Control Circuit Voltage Compatibility | Compatible with AC 100V. For other voltage requirements, please consult us. |

| ④ | Chilled Water Freeze Prevention Heater | To prevent freezing of chilled water, an electric heater is installed. (202A2: 10kW, 402A2: 15kW, 602A2: 20kW, 802A2: 30kW) |

| ⑤ | Anti-Corrosion (Salt-Resistant) Specification | For installations near the coast, special specification coatings are applied. |

| ⑥ | High Flow Rate Specification | If the flow rate exceeds 150% of the standard, please consult us individually. (For flow rate ratio details, refer to “9. Standard Cooling Capacity Curve.”) |

| ⑦ | Other Custom Options | Please consult us if you have any specific requests. (Examples: Low-noise specifications, snow accumulation countermeasures, wind protection measures, protective net, etc.) |

Related Products

-

Kuwana Metals SAM SFC1480FX / SFC2480FX Series Mass Flow Controller

-

Kuwana Metals Aera HG200 Series HC100/HM100 Series Pressure Insensitive (PI) Mass Flow Controller/Digital Mass Flow Controller (Non-PI) Mass Flow Meter

-

Kuwana Metals Malleable Iron Pipe Fittings For General Use

-

Kuwana Metals S-A075M Chilled Tower

-

Kuwana Metals SAM PS200 Series Pressure-Based PI Mass Flow Controller

-

Kuwana Metals Aera FC-R7800 Series Mass Flow Controller